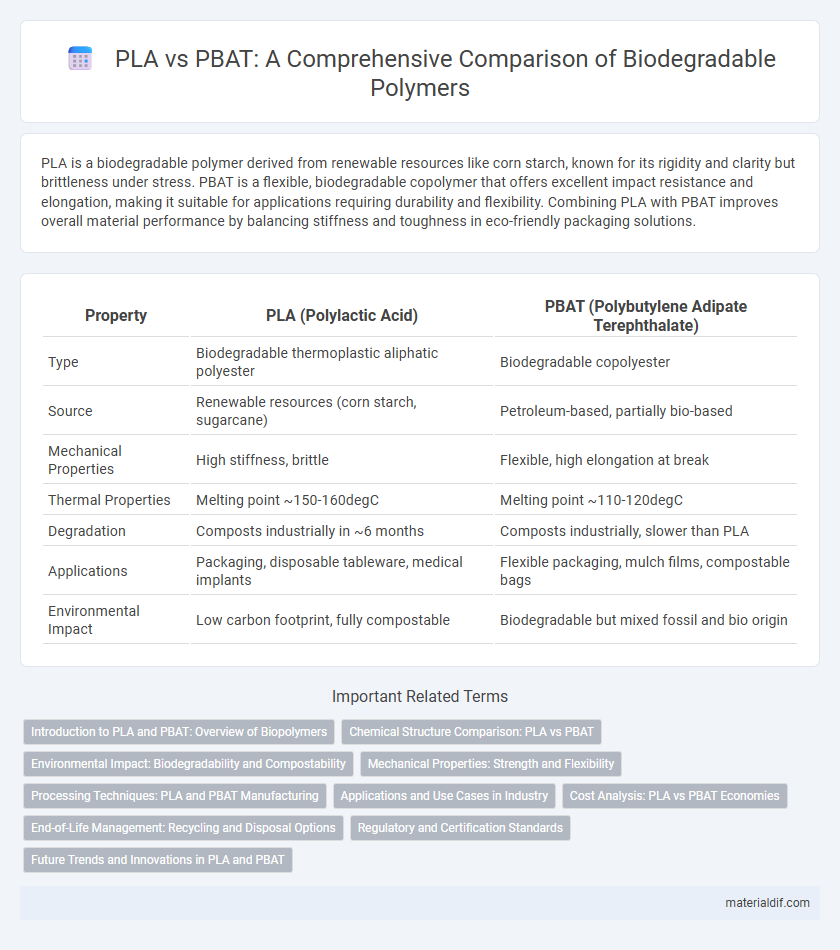

PLA is a biodegradable polymer derived from renewable resources like corn starch, known for its rigidity and clarity but brittleness under stress. PBAT is a flexible, biodegradable copolymer that offers excellent impact resistance and elongation, making it suitable for applications requiring durability and flexibility. Combining PLA with PBAT improves overall material performance by balancing stiffness and toughness in eco-friendly packaging solutions.

Table of Comparison

| Property | PLA (Polylactic Acid) | PBAT (Polybutylene Adipate Terephthalate) |

|---|---|---|

| Type | Biodegradable thermoplastic aliphatic polyester | Biodegradable copolyester |

| Source | Renewable resources (corn starch, sugarcane) | Petroleum-based, partially bio-based |

| Mechanical Properties | High stiffness, brittle | Flexible, high elongation at break |

| Thermal Properties | Melting point ~150-160degC | Melting point ~110-120degC |

| Degradation | Composts industrially in ~6 months | Composts industrially, slower than PLA |

| Applications | Packaging, disposable tableware, medical implants | Flexible packaging, mulch films, compostable bags |

| Environmental Impact | Low carbon footprint, fully compostable | Biodegradable but mixed fossil and bio origin |

Introduction to PLA and PBAT: Overview of Biopolymers

PLA (Polylactic Acid) and PBAT (Polybutylene Adipate Terephthalate) are prominent biopolymers used in sustainable packaging and biodegradable products. PLA is derived from renewable resources like corn starch or sugarcane, exhibiting high rigidity and clarity, making it ideal for disposable items. PBAT, a flexible and fully biodegradable aliphatic-aromatic copolyester, complements PLA by enhancing toughness and elasticity in composite materials.

Chemical Structure Comparison: PLA vs PBAT

Polylactic acid (PLA) is a linear aliphatic polyester derived from lactic acid, characterized by its rigid and crystalline structure due to the presence of ester linkages and chiral centers along the polymer chain. Polybutylene adipate terephthalate (PBAT) is a copolymer consisting of butylene adipate and butylene terephthalate units, combining flexible aliphatic segments with aromatic rings that impart elasticity and biodegradability. The chemical structure of PLA results in higher tensile strength and brittleness, while PBAT's copolymer architecture provides superior flexibility and toughness.

Environmental Impact: Biodegradability and Compostability

PLA (Polylactic Acid) and PBAT (Polybutylene Adipate Terephthalate) differ significantly in environmental impact, particularly in biodegradability and compostability. PLA is derived from renewable resources like corn starch and is industrially compostable under specific conditions, offering a lower carbon footprint but limited biodegradability in natural environments. PBAT is a petroleum-based biodegradable polymer with superior flexibility and biodegradability in both industrial and home composting conditions, making it a versatile option for reducing plastic waste in various environmental settings.

Mechanical Properties: Strength and Flexibility

PLA (Polylactic Acid) exhibits high tensile strength and stiffness, making it suitable for rigid applications but tends to be brittle with low elongation at break. PBAT (Polybutylene Adipate Terephthalate) offers superior flexibility and impact resistance due to its elastomeric nature, with much higher elongation at break and lower tensile strength compared to PLA. Blending PLA with PBAT improves mechanical properties by balancing strength and flexibility, enhancing overall toughness for packaging and biodegradable products.

Processing Techniques: PLA and PBAT Manufacturing

PLA is primarily processed through injection molding, extrusion, and thermoforming due to its rigidity and low melting point of approximately 150-160degC. PBAT offers greater flexibility in processing, easily adaptable to blow molding, film extrusion, and injection molding with a higher melting range of about 110-125degC. Both PLA and PBAT require precise temperature control and moisture management during manufacturing to maintain polymer integrity and optimize material properties.

Applications and Use Cases in Industry

PLA (Polylactic Acid) is widely used in packaging, disposable tableware, and agricultural films due to its biodegradability and compostability, making it ideal for eco-friendly products. PBAT (Polybutylene Adipate Terephthalate) offers flexibility and durability, which are crucial for applications like mulch films, flexible packaging, and garbage bags where mechanical strength and biodegradability are essential. Industries favor PLA for rigid applications requiring clarity and stiffness, while PBAT is preferred in flexible and stretchable materials to enhance performance and environmental sustainability.

Cost Analysis: PLA vs PBAT Economies

PLA offers a lower production cost due to its bio-based raw materials and simpler manufacturing process, making it economically favorable for large-scale applications. PBAT, with its higher flexibility and biodegradability, incurs increased expenses related to petrochemical feedstocks and more complex synthesis. Cost analysis reveals PLA's dominance in cost-efficiency, while PBAT's specialized uses justify its premium pricing in niche markets.

End-of-Life Management: Recycling and Disposal Options

PLA (Polylactic Acid) is a biodegradable polymer that composts efficiently in industrial composting facilities, but its recycling options remain limited due to contamination risks and lack of widespread collection systems. PBAT (Polybutylene Adipate Terephthalate) offers greater flexibility in mechanical recycling and can degrade under composting conditions, yet it requires specific environments to break down effectively, complicating disposal. Effective end-of-life management for both polymers depends on enhancing sorting technologies and expanding infrastructure for composting and recycling to reduce landfill accumulation.

Regulatory and Certification Standards

PLA (Polylactic Acid) complies with FDA and EU regulations for food contact materials, ensuring its safety for packaging and disposable items, while PBAT (Polybutylene Adipate Terephthalate) meets ASTM D6400 and EN 13432 standards for compostability, crucial for certified biodegradable products. PLA's certification under ISO 10993 confirms its biocompatibility for medical applications, whereas PBAT's certification aligns with industrial composting and biodegradation requirements, supporting its use in eco-friendly films and bags. Both polymers adhere to REACH regulations, but differences in certification pathways affect their suitability for specific regulatory environments and market demands.

Future Trends and Innovations in PLA and PBAT

Future trends in PLA focus on enhancing its biodegradability and mechanical properties through advanced catalyst systems and bio-based additives, promoting wider applications in sustainable packaging and medical devices. PBAT innovations target improving its flexibility and compostability by blending with bio-resins and optimizing polymerization processes, making it a preferred choice for eco-friendly agricultural films and flexible packaging. Emerging research into PLA-PBAT copolymers aims to combine the strengths of both materials, driving market growth in fully compostable and high-performance bioplastics.

PLA vs PBAT Infographic

materialdif.com

materialdif.com