UV-stabilized polymer PET offers enhanced resistance to degradation from ultraviolet light, extending the material's durability and maintaining its mechanical properties in outdoor applications. Non-stabilized PET, lacking such protection, tends to become brittle and discolored when exposed to prolonged sunlight. Selecting UV-stabilized PET ensures optimal performance and longevity in environments subject to UV radiation.

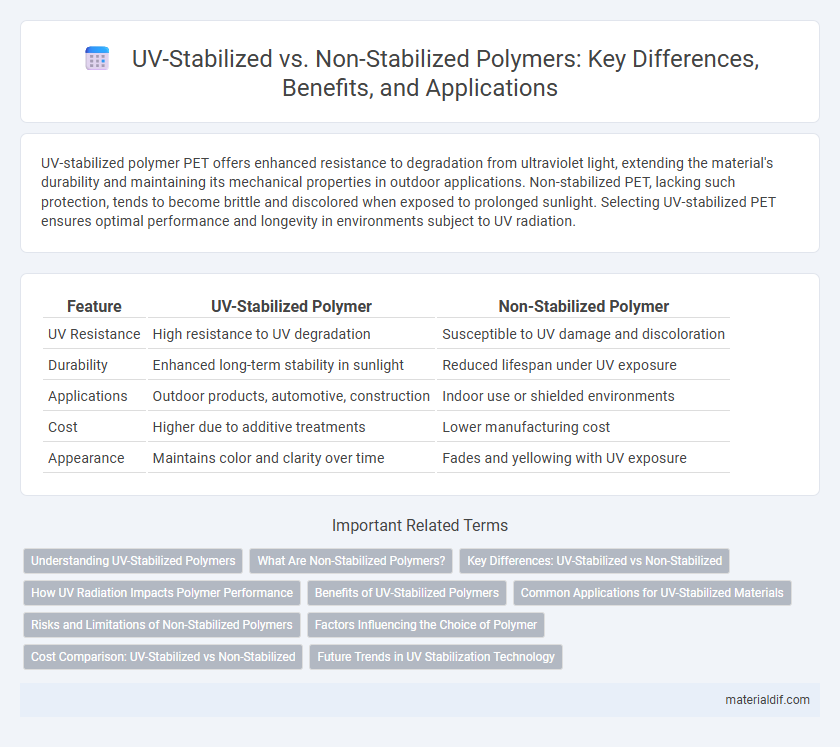

Table of Comparison

| Feature | UV-Stabilized Polymer | Non-Stabilized Polymer |

|---|---|---|

| UV Resistance | High resistance to UV degradation | Susceptible to UV damage and discoloration |

| Durability | Enhanced long-term stability in sunlight | Reduced lifespan under UV exposure |

| Applications | Outdoor products, automotive, construction | Indoor use or shielded environments |

| Cost | Higher due to additive treatments | Lower manufacturing cost |

| Appearance | Maintains color and clarity over time | Fades and yellowing with UV exposure |

Understanding UV-Stabilized Polymers

UV-stabilized polymers incorporate additives such as UV absorbers and hindered amine light stabilizers (HALS) that prevent degradation caused by ultraviolet radiation, thereby enhancing material longevity and performance. These stabilizers work by absorbing harmful UV rays or neutralizing free radicals generated during UV exposure, which otherwise cause polymer chain scission and discoloration. Understanding the mechanisms of UV stabilization is crucial for selecting appropriate polymers in outdoor applications, ensuring durability in environments with intense sunlight.

What Are Non-Stabilized Polymers?

Non-stabilized polymers lack additives that protect against ultraviolet (UV) radiation, making them prone to degradation when exposed to sunlight. This degradation typically results in reduced mechanical strength, discoloration, and surface cracking due to photo-oxidation processes. Without UV stabilizers such as UV absorbers or hindered amine light stabilizers (HALS), these polymers have limited outdoor durability and shorter lifespans.

Key Differences: UV-Stabilized vs Non-Stabilized

UV-stabilized polymers contain additives such as UV absorbers and hindered amine light stabilizers (HALS) that protect the material from degradation caused by ultraviolet radiation, enhancing durability and color retention. Non-stabilized polymers lack these protective agents, leading to accelerated photodegradation, brittleness, discoloration, and reduced mechanical performance when exposed to sunlight. This fundamental difference impacts the polymer's lifespan and suitability for outdoor applications requiring prolonged UV exposure resistance.

How UV Radiation Impacts Polymer Performance

UV radiation causes polymer chains to break down through photo-oxidation, leading to discoloration, loss of mechanical strength, and surface cracking. UV-stabilized polymers incorporate additives such as UV absorbers and hindered amine light stabilizers (HALS), which significantly slow degradation by absorbing or neutralizing harmful UV rays. Non-stabilized polymers degrade rapidly under UV exposure, resulting in reduced lifespan and compromised performance in outdoor applications.

Benefits of UV-Stabilized Polymers

UV-stabilized polymers exhibit significantly enhanced durability and longevity by resisting degradation caused by ultraviolet radiation, which commonly leads to brittleness, discoloration, and loss of mechanical properties in non-stabilized polymers. Incorporation of UV stabilizers, such as hindered amine light stabilizers (HALS) and UV absorbers, prevents polymer chain scission and maintains structural integrity, extending service life in outdoor applications. These benefits reduce maintenance costs and improve performance in industries like automotive, construction, and packaging exposed to prolonged sunlight.

Common Applications for UV-Stabilized Materials

UV-stabilized polymers are essential in outdoor applications such as automotive parts, construction materials, and agricultural films, where prolonged exposure to sunlight can cause discoloration, brittleness, and degradation. These materials incorporate UV absorbers or hindered amine light stabilizers (HALS) to enhance durability and maintain mechanical properties under UV radiation. Non-stabilized polymers lack this protection, making them unsuitable for long-term outdoor use due to rapid weathering and performance loss.

Risks and Limitations of Non-Stabilized Polymers

Non-stabilized polymers are highly susceptible to degradation when exposed to ultraviolet (UV) radiation, leading to significant risks such as discoloration, loss of mechanical strength, and surface cracking. This degradation accelerates polymer chain scission and oxidation processes, resulting in reduced lifespan and compromised material performance in outdoor applications. Without UV stabilizers like HALS (Hindered Amine Light Stabilizers) or UV absorbers, non-stabilized polymers face limitations in durability, adversely affecting product reliability and increasing maintenance costs.

Factors Influencing the Choice of Polymer

UV-stabilized polymers resist degradation caused by ultraviolet light, making them ideal for outdoor and prolonged sun exposure applications, whereas non-stabilized polymers are more prone to fading, cracking, and loss of mechanical properties. Factors influencing the choice include environmental exposure, desired longevity, cost constraints, and specific application requirements such as flexibility or transparency. Selecting UV-stabilized polymers enhances durability and performance in harsh UV environments, while non-stabilized options may be suitable for indoor or short-term use where UV degradation is minimal.

Cost Comparison: UV-Stabilized vs Non-Stabilized

UV-stabilized polymers generally incur higher upfront costs due to the incorporation of specialized UV inhibitors or absorbers that extend material lifespan by preventing photodegradation. Non-stabilized polymers are cheaper initially but often require more frequent replacement or maintenance, resulting in higher long-term expenses. Evaluating total cost of ownership, UV-stabilized variants provide better economic value in outdoor or UV-exposed applications despite the premium price.

Future Trends in UV Stabilization Technology

Emerging advancements in UV stabilization technology for polymers include the integration of nanoparticle additives and smart UV absorbers that enhance durability and extend material lifespan under extreme solar exposure. Research emphasizes bio-based UV stabilizers to align with sustainable manufacturing practices, reducing environmental impact while maintaining performance. Future trends also point to the development of multifunctional coatings combining UV stabilization with self-healing and anti-corrosive properties to optimize polymer resilience in various industrial applications.

UV-Stabilized vs Non-Stabilized Infographic

materialdif.com

materialdif.com