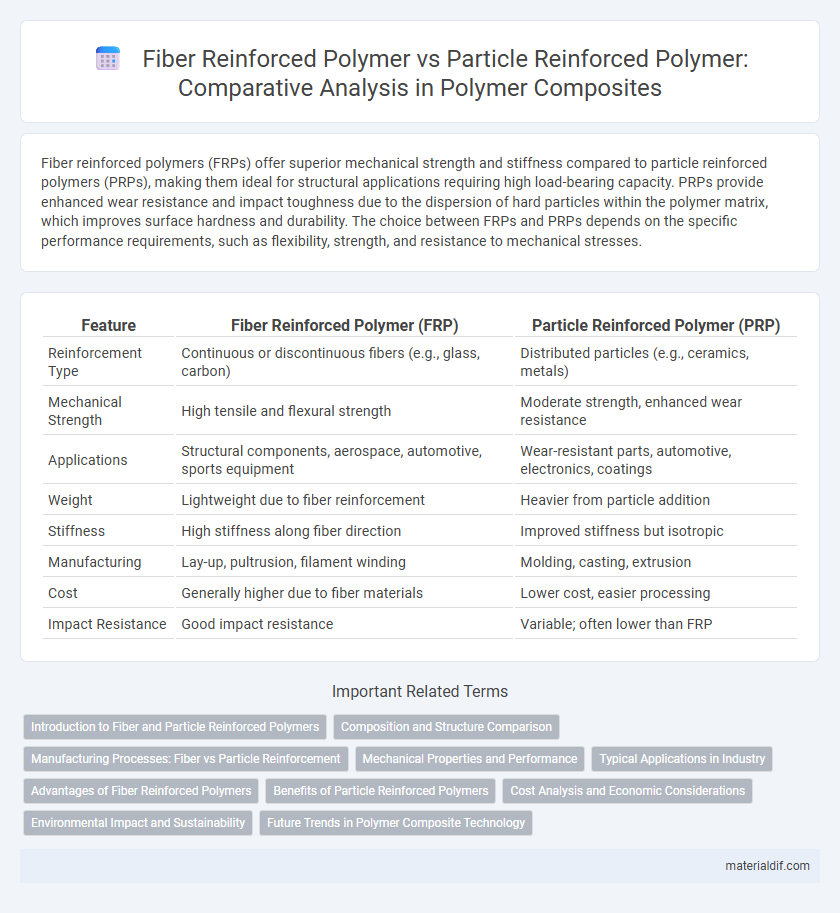

Fiber reinforced polymers (FRPs) offer superior mechanical strength and stiffness compared to particle reinforced polymers (PRPs), making them ideal for structural applications requiring high load-bearing capacity. PRPs provide enhanced wear resistance and impact toughness due to the dispersion of hard particles within the polymer matrix, which improves surface hardness and durability. The choice between FRPs and PRPs depends on the specific performance requirements, such as flexibility, strength, and resistance to mechanical stresses.

Table of Comparison

| Feature | Fiber Reinforced Polymer (FRP) | Particle Reinforced Polymer (PRP) |

|---|---|---|

| Reinforcement Type | Continuous or discontinuous fibers (e.g., glass, carbon) | Distributed particles (e.g., ceramics, metals) |

| Mechanical Strength | High tensile and flexural strength | Moderate strength, enhanced wear resistance |

| Applications | Structural components, aerospace, automotive, sports equipment | Wear-resistant parts, automotive, electronics, coatings |

| Weight | Lightweight due to fiber reinforcement | Heavier from particle addition |

| Stiffness | High stiffness along fiber direction | Improved stiffness but isotropic |

| Manufacturing | Lay-up, pultrusion, filament winding | Molding, casting, extrusion |

| Cost | Generally higher due to fiber materials | Lower cost, easier processing |

| Impact Resistance | Good impact resistance | Variable; often lower than FRP |

Introduction to Fiber and Particle Reinforced Polymers

Fiber Reinforced Polymers (FRPs) consist of polymer matrices embedded with continuous or discontinuous fibers such as glass, carbon, or aramid, which significantly enhance tensile strength and stiffness. Particle Reinforced Polymers (PRPs) include polymer matrices filled with particulate materials like ceramics, metals, or carbon black, improving wear resistance and impact strength. Both reinforcement types optimize polymer properties for diverse applications, with fibers providing superior load-bearing capacity and particles enhancing surface hardness and durability.

Composition and Structure Comparison

Fiber Reinforced Polymers (FRPs) consist of continuous or discontinuous fibers such as glass, carbon, or aramid embedded in a polymer matrix, providing high tensile strength and stiffness along the fiber direction. Particle Reinforced Polymers incorporate discrete particles like ceramic or metallic fillers dispersed within the polymer matrix, enhancing properties such as wear resistance and impact toughness without significantly increasing stiffness. The anisotropic nature of FRPs contrasts with the more isotropic behavior of Particle Reinforced Polymers due to differences in reinforcement geometry and distribution.

Manufacturing Processes: Fiber vs Particle Reinforcement

Fiber Reinforced Polymer (FRP) manufacturing involves aligning continuous or chopped fibers within a polymer matrix using processes such as filament winding, pultrusion, or hand lay-up to achieve directional strength and stiffness. In contrast, Particle Reinforced Polymer (PRP) manufacturing disperses particulate fillers like ceramic particles or metal powders uniformly within the polymer through methods including injection molding or casting, enhancing isotropic properties like wear resistance and thermal stability. The key manufacturing distinction lies in the fiber orientation control in FRP versus the homogeneous particle distribution in PRP, leading to different mechanical and physical performance outcomes.

Mechanical Properties and Performance

Fiber Reinforced Polymers (FRPs) exhibit superior tensile strength, stiffness, and impact resistance compared to Particle Reinforced Polymers (PRPs) due to the continuous fiber architecture that efficiently transfers load and resists deformation. PRPs typically offer enhanced hardness and wear resistance but have lower tensile strength and ductility, making them more suitable for applications requiring abrasion resistance rather than structural load-bearing capacity. The anisotropic mechanical performance of FRPs allows for tailored strength along fiber directions, whereas PRPs provide more isotropic properties with moderate improvements in toughness and thermal stability.

Typical Applications in Industry

Fiber Reinforced Polymers (FRPs) are predominantly utilized in aerospace, automotive, and construction industries due to their high strength-to-weight ratio and exceptional fatigue resistance. Particle Reinforced Polymers (PRPs) are commonly found in applications requiring enhanced wear resistance and thermal stability, such as automotive engine components and electronic housings. Both composite types improve material performance but are selected based on specific industry demands like load-bearing capacity or thermal endurance.

Advantages of Fiber Reinforced Polymers

Fiber Reinforced Polymers (FRPs) offer superior mechanical strength and stiffness compared to Particle Reinforced Polymers (PRPs), enabling enhanced load-bearing capacity and structural performance. The continuous fiber alignment in FRPs results in improved fatigue resistance and higher tensile strength, making them ideal for aerospace, automotive, and civil engineering applications. Moreover, FRPs exhibit better anisotropic properties and impact resistance, contributing to their widespread use in critical, high-performance environments.

Benefits of Particle Reinforced Polymers

Particle Reinforced Polymers exhibit enhanced toughness and improved impact resistance compared to Fiber Reinforced Polymers, making them ideal for applications requiring durability under dynamic loads. Their isotropic properties provide uniform strength distribution, reducing the risk of weak points seen in fiber-aligned composites. These polymers also offer cost-effective manufacturing processes and better resistance to wear and abrasion in industrial environments.

Cost Analysis and Economic Considerations

Fiber Reinforced Polymers (FRPs) generally incur higher initial costs due to the complexity of fiber extraction and alignment processes, while Particle Reinforced Polymers (PRPs) benefit from lower raw material expenses and simpler manufacturing techniques. Economic considerations favor PRPs in large-scale production where cost efficiency is critical, whereas FRPs offer superior mechanical properties justifying their premium in specialized applications. Lifecycle cost analysis often reveals FRPs deliver better long-term value through enhanced durability and performance, offsetting their upfront investment in sectors like aerospace and automotive engineering.

Environmental Impact and Sustainability

Fiber Reinforced Polymers (FRPs) typically exhibit higher strength-to-weight ratios and longer service life, contributing to reduced material consumption and lower carbon footprints in structural applications. Particle Reinforced Polymers (PRPs), while often easier to recycle due to their simpler matrix reinforcement, may have lower durability, leading to more frequent replacements that can increase environmental burdens over time. Sustainable strategies for both include the use of bio-based resins and recycled fibers or particles to enhance circularity and minimize ecological impact.

Future Trends in Polymer Composite Technology

Fiber Reinforced Polymers (FRPs) continue to dominate aerospace and automotive sectors due to their superior strength-to-weight ratio and directional mechanical properties, while Particle Reinforced Polymers (PRPs) gain traction in applications requiring enhanced wear resistance and thermal stability. Advances in nanotechnology and hybrid reinforcement methods are driving future trends, with researchers focusing on integrating carbon nanotubes and graphene within polymer matrices to boost mechanical performance and multifunctionality. Sustainable and recyclable composite materials are also emerging priorities, aligning polymer composite technology with circular economy principles and environmental regulations.

Fiber Reinforced Polymer vs Particle Reinforced Polymer Infographic

materialdif.com

materialdif.com