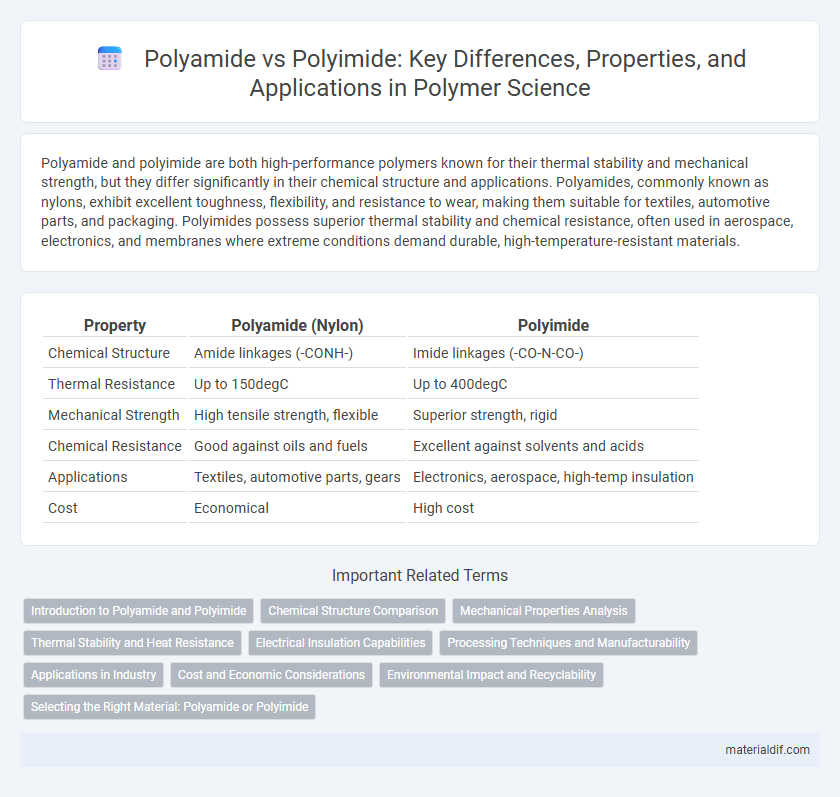

Polyamide and polyimide are both high-performance polymers known for their thermal stability and mechanical strength, but they differ significantly in their chemical structure and applications. Polyamides, commonly known as nylons, exhibit excellent toughness, flexibility, and resistance to wear, making them suitable for textiles, automotive parts, and packaging. Polyimides possess superior thermal stability and chemical resistance, often used in aerospace, electronics, and membranes where extreme conditions demand durable, high-temperature-resistant materials.

Table of Comparison

| Property | Polyamide (Nylon) | Polyimide |

|---|---|---|

| Chemical Structure | Amide linkages (-CONH-) | Imide linkages (-CO-N-CO-) |

| Thermal Resistance | Up to 150degC | Up to 400degC |

| Mechanical Strength | High tensile strength, flexible | Superior strength, rigid |

| Chemical Resistance | Good against oils and fuels | Excellent against solvents and acids |

| Applications | Textiles, automotive parts, gears | Electronics, aerospace, high-temp insulation |

| Cost | Economical | High cost |

Introduction to Polyamide and Polyimide

Polyamide, commonly known as nylon, is a versatile polymer characterized by repeating amide linkages in its backbone, renowned for its high strength, flexibility, and resistance to abrasion and chemicals. Polyimide, distinguished by its imide functional groups, exhibits exceptional thermal stability, mechanical strength, and resistance to harsh chemical and radiation environments, making it ideal for advanced electronics and aerospace applications. Both polymers serve critical roles in engineering and industrial sectors, with polyamide favored for everyday durable goods and polyimide utilized in specialized high-performance materials.

Chemical Structure Comparison

Polyamide features repeating amide groups (-CONH-) in its backbone, which provide hydrogen bonding that enhances mechanical strength and thermal resistance. Polyimide contains imide groups with two acyl groups attached to nitrogen, forming a rigid, aromatic backbone that offers superior thermal stability and chemical resistance. The key structural difference lies in the presence of amide bonds in polyamides versus imide rings in polyimides, influencing their distinct physicochemical properties.

Mechanical Properties Analysis

Polyamide exhibits high tensile strength and excellent impact resistance, making it suitable for demanding mechanical applications. Polyimide offers superior thermal stability and maintains mechanical integrity at elevated temperatures, outperforming polyamide in heat-resistant environments. The choice between polyamide and polyimide depends on the required balance of mechanical durability and thermal endurance in the target application.

Thermal Stability and Heat Resistance

Polyimide exhibits superior thermal stability compared to polyamide, maintaining structural integrity at temperatures above 400degC, whereas polyamide typically withstands up to 150-250degC. The aromatic imide rings in polyimide contribute to its exceptional heat resistance and ability to endure prolonged exposure to extreme thermal conditions. Polyamide's aliphatic structure limits its high-temperature performance, making it less suitable for applications requiring long-term heat exposure.

Electrical Insulation Capabilities

Polyimide exhibits superior electrical insulation capabilities compared to polyamide due to its high thermal stability and excellent dielectric properties, making it ideal for advanced electronic applications. Polyamide offers good insulation but is less effective under extreme temperature and chemical exposure, limiting its use in high-performance electrical components. The intrinsic aromatic structure of polyimide contributes to lower dielectric constant and loss, enhancing signal integrity in microelectronics and flexible circuits.

Processing Techniques and Manufacturability

Polyamide typically offers easier processing techniques such as injection molding, extrusion, and blow molding due to its lower melting point and thermoplastic nature, enabling high-volume manufacturability with rapid cycle times. In contrast, polyimide requires more specialized processing methods including advanced thermoset molding and film casting, often involving high-temperature curing to achieve its superior thermal stability and mechanical properties. Manufacturers favor polyimide in applications demanding extreme heat resistance and chemical stability despite more complex and costly processing compared to the more versatile and cost-effective polyamide.

Applications in Industry

Polyamide polymers are widely used in automotive manufacturing due to their excellent mechanical strength, chemical resistance, and ease of processing, making them ideal for fuel lines, gears, and electrical connectors. Polyimides, known for exceptional thermal stability and electrical insulation properties, find critical applications in aerospace and electronics industries, including flexible printed circuit boards, insulating films, and high-temperature adhesive components. Industrial sectors prioritize polyamides for durability and cost-effectiveness, while polyimides are preferred for advanced performance in extreme environments requiring sustained thermal and chemical integrity.

Cost and Economic Considerations

Polyamide typically offers a lower-cost solution compared to polyimide, making it more suitable for budget-sensitive applications where moderate thermal stability and mechanical strength are required. Polyimide commands a higher price due to its superior heat resistance, chemical stability, and performance in extreme environments, justifying the investment in high-performance industries such as aerospace and electronics. Economic considerations favor polyamide for large-scale manufacturing and consumer goods, while polyimide is preferred in specialized, high-value applications despite its elevated cost.

Environmental Impact and Recyclability

Polyamide generally has a lower environmental impact due to its easier recyclability and biodegradability compared to polyimide, which is more chemically stable and resistant to degradation. Polyimide's complex aromatic structure makes recycling challenging and limits its environmental friendliness, often requiring specialized thermal or chemical processing. Polyamide's ability to be mechanically recycled and broken down biologically contributes to a more sustainable lifecycle in various industrial and textile applications.

Selecting the Right Material: Polyamide or Polyimide

Polyamide offers excellent mechanical strength and chemical resistance, making it ideal for applications requiring flexibility and durability under moderate thermal conditions up to 150degC. Polyimide, known for its superior thermal stability and electrical insulation properties, performs exceptionally well in high-temperature environments exceeding 300degC and demanding advanced solvent resistance. Selecting the right material depends on the specific application conditions, balancing factors such as thermal stability, mechanical performance, and chemical exposure.

Polyamide vs Polyimide Infographic

materialdif.com

materialdif.com