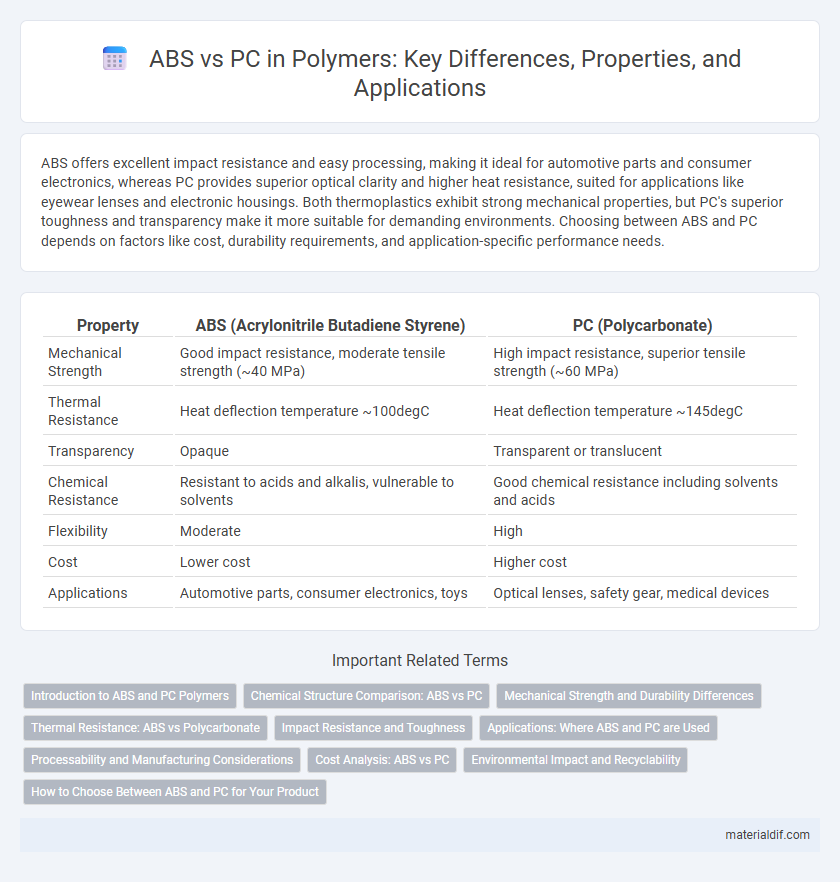

ABS offers excellent impact resistance and easy processing, making it ideal for automotive parts and consumer electronics, whereas PC provides superior optical clarity and higher heat resistance, suited for applications like eyewear lenses and electronic housings. Both thermoplastics exhibit strong mechanical properties, but PC's superior toughness and transparency make it more suitable for demanding environments. Choosing between ABS and PC depends on factors like cost, durability requirements, and application-specific performance needs.

Table of Comparison

| Property | ABS (Acrylonitrile Butadiene Styrene) | PC (Polycarbonate) |

|---|---|---|

| Mechanical Strength | Good impact resistance, moderate tensile strength (~40 MPa) | High impact resistance, superior tensile strength (~60 MPa) |

| Thermal Resistance | Heat deflection temperature ~100degC | Heat deflection temperature ~145degC |

| Transparency | Opaque | Transparent or translucent |

| Chemical Resistance | Resistant to acids and alkalis, vulnerable to solvents | Good chemical resistance including solvents and acids |

| Flexibility | Moderate | High |

| Cost | Lower cost | Higher cost |

| Applications | Automotive parts, consumer electronics, toys | Optical lenses, safety gear, medical devices |

Introduction to ABS and PC Polymers

ABS (Acrylonitrile Butadiene Styrene) is a common thermoplastic polymer known for its toughness, impact resistance, and ease of processing, making it ideal for automotive parts, consumer electronics, and toys. PC (Polycarbonate) exhibits high impact strength, transparency, and heat resistance, widely used in optical discs, eyewear lenses, and medical devices. Both polymers serve diverse applications but differ in mechanical properties and chemical resistance, influencing their selection in engineering and manufacturing.

Chemical Structure Comparison: ABS vs PC

ABS (Acrylonitrile Butadiene Styrene) features a copolymer composed of acrylonitrile, butadiene, and styrene units, giving it a heterogeneous structure with rubbery butadiene segments for impact resistance and styrenic units for rigidity. PC (Polycarbonate) is a linear polymer consisting of bisphenol A linked by carbonate groups, resulting in a highly transparent, amorphous thermoplastic with superior thermal stability and toughness. The key chemical difference lies in ABS's multi-phase copolymer system versus PC's uniform carbonate backbone, influencing their mechanical and thermal properties.

Mechanical Strength and Durability Differences

ABS (Acrylonitrile Butadiene Styrene) offers good impact resistance and toughness, making it suitable for applications needing moderate mechanical strength. Polycarbonate (PC) exhibits superior mechanical strength with higher impact resistance and excellent durability, often used where enhanced toughness and long-term performance are critical. The difference in molecular structure grants PC higher tensile strength and resistance to deformation compared to ABS, resulting in greater durability under heavy mechanical stress.

Thermal Resistance: ABS vs Polycarbonate

Polycarbonate (PC) exhibits superior thermal resistance compared to Acrylonitrile Butadiene Styrene (ABS), with a heat deflection temperature typically around 140degC, while ABS withstands approximately 100degC. The higher glass transition temperature of PC makes it suitable for applications requiring prolonged exposure to elevated temperatures. Consequently, polycarbonate is preferred in environments demanding enhanced thermal stability and durability.

Impact Resistance and Toughness

ABS (Acrylonitrile Butadiene Styrene) offers good impact resistance with moderate toughness, making it suitable for applications requiring durability and flexibility under sudden forces. PC (Polycarbonate) exhibits superior impact resistance and exceptional toughness due to its high molecular weight and amorphous structure, allowing it to withstand significant mechanical stress without cracking. When comparing ABS and PC, polycarbonate consistently outperforms ABS in impact strength, making it ideal for high-impact demanding environments such as safety helmets and automotive parts.

Applications: Where ABS and PC are Used

ABS (Acrylonitrile Butadiene Styrene) is widely used in automotive parts, consumer electronics housings, and household appliances due to its excellent impact resistance and ease of molding. PC (Polycarbonate) is preferred for applications requiring high optical clarity and superior heat resistance, such as eyewear lenses, medical devices, and safety helmets. Both polymers serve crucial roles in manufacturing but are selected based on specific performance needs like transparency for PC or cost-effectiveness for ABS.

Processability and Manufacturing Considerations

ABS offers superior processability due to its lower melting point and better flow characteristics, enabling faster injection molding cycles and reduced energy consumption. PC requires higher processing temperatures and more precise thermal control to prevent degradation, which can increase manufacturing complexity and cost. Tooling for ABS is generally more durable under typical processing conditions, while PC demands robust molds capable of withstanding elevated temperatures and pressures to maintain part quality.

Cost Analysis: ABS vs PC

ABS (Acrylonitrile Butadiene Styrene) offers a lower upfront material cost compared to PC (Polycarbonate), making it more economical for high-volume applications. PC generally incurs higher processing expenses due to its elevated melting point and requirement for specialized equipment, which can impact overall production costs. Cost analysis reveals ABS as the preferred choice for budget-sensitive projects, while PC justifies its premium with superior mechanical properties and heat resistance.

Environmental Impact and Recyclability

ABS (Acrylonitrile Butadiene Styrene) is less environmentally friendly due to its lower recyclability and longer degradation time, contributing to persistent plastic waste. PC (Polycarbonate) offers better recyclability with efficient reuse in industrial applications, reducing landfill accumulation and conserving resources. Both polymers require advanced recycling processes to minimize environmental impact, yet PC's chemical structure enables more effective recovery and repurposing.

How to Choose Between ABS and PC for Your Product

Choosing between ABS and PC depends on the specific requirements of your product, such as impact resistance, heat tolerance, and surface finish. ABS offers excellent machinability and cost-effectiveness with moderate strength, making it ideal for consumer electronics and automotive parts. PC provides superior toughness, higher heat resistance, and transparency, suitable for applications demanding durability and optical clarity like safety helmets and eyewear lenses.

ABS vs PC Infographic

materialdif.com

materialdif.com