Extrusion involves forcing molten polymer through a shaped die to produce continuous profiles like pipes, sheets, or films, offering precise control over thickness and dimensions. Blow molding shapes hollow plastic parts by inflating molten polymer inside a mold cavity, making it ideal for producing containers such as bottles with uniform wall thickness. Both processes differ in their applications, with extrusion suited for solid or tubular shapes and blow molding optimized for hollow, seamless products.

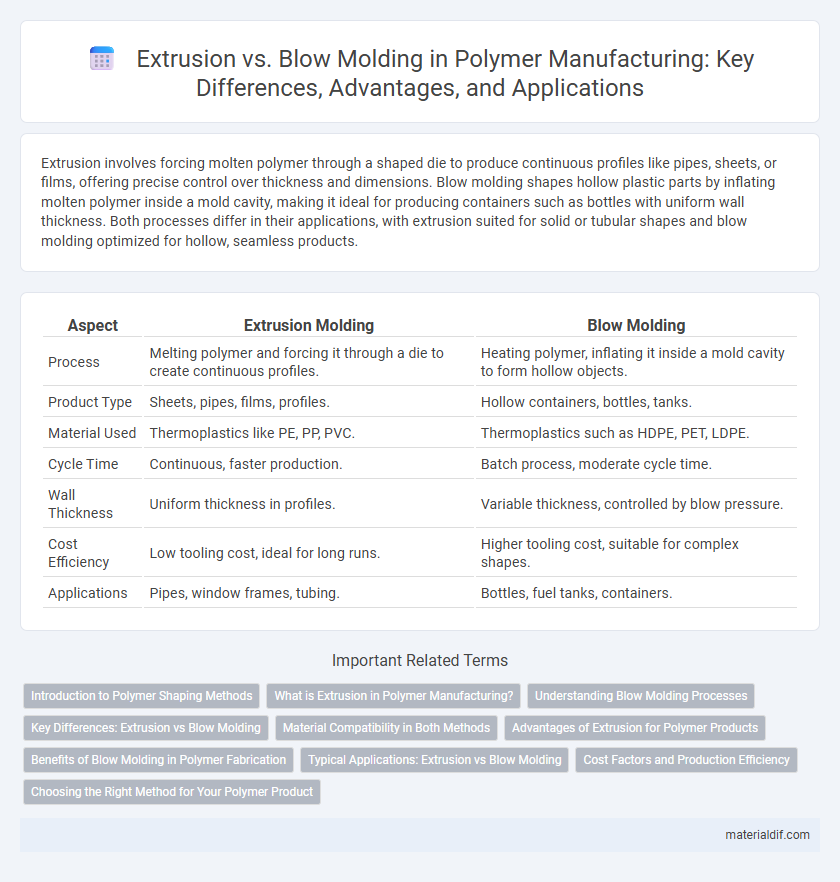

Table of Comparison

| Aspect | Extrusion Molding | Blow Molding |

|---|---|---|

| Process | Melting polymer and forcing it through a die to create continuous profiles. | Heating polymer, inflating it inside a mold cavity to form hollow objects. |

| Product Type | Sheets, pipes, films, profiles. | Hollow containers, bottles, tanks. |

| Material Used | Thermoplastics like PE, PP, PVC. | Thermoplastics such as HDPE, PET, LDPE. |

| Cycle Time | Continuous, faster production. | Batch process, moderate cycle time. |

| Wall Thickness | Uniform thickness in profiles. | Variable thickness, controlled by blow pressure. |

| Cost Efficiency | Low tooling cost, ideal for long runs. | Higher tooling cost, suitable for complex shapes. |

| Applications | Pipes, window frames, tubing. | Bottles, fuel tanks, containers. |

Introduction to Polymer Shaping Methods

Extrusion and blow molding are fundamental polymer shaping methods distinguished by their processing techniques and end-use applications. Extrusion forces molten polymer through a shaped die to create continuous profiles such as pipes and sheets, optimizing material uniformity and production efficiency. Blow molding inflates a heated polymer tube within a mold cavity to form hollow products like bottles, enabling precise wall thickness control and complex geometries.

What is Extrusion in Polymer Manufacturing?

Extrusion in polymer manufacturing is a continuous process where melted plastic material is forced through a shaped die to create long objects with a consistent cross-section, such as pipes, sheets, or films. The polymer resin is heated until it reaches a molten state, then pushed through the die using a screw mechanism, ensuring uniformity and precise dimensions. This method is highly efficient for producing large quantities of products with complex profiles and smooth surface finishes.

Understanding Blow Molding Processes

Blow molding is a polymer processing technique used to create hollow plastic parts by inflating a heated plastic tube against a mold cavity, enabling complex shapes such as bottles and containers. Unlike extrusion, which produces continuous profiles by forcing molten polymer through a die, blow molding focuses on shaping molten polymer into hollow forms through air pressure expansion. Key blow molding methods include extrusion blow molding, injection blow molding, and stretch blow molding, each tailored for specific product requirements and material characteristics.

Key Differences: Extrusion vs Blow Molding

Extrusion and blow molding are distinct polymer processing techniques primarily differentiated by their shaping methods; extrusion forces melted polymer through a die to create continuous profiles, while blow molding inflates heated polymer into a mold cavity to form hollow objects. Extrusion is ideal for producing pipes, sheets, and films, emphasizing uniform cross-sectional areas, whereas blow molding excels in manufacturing containers like bottles with complex hollow shapes. Material flow, mold design, and product geometry directly influence process selection, with extrusion favoring linear shapes and blow molding enabling three-dimensional hollow structures.

Material Compatibility in Both Methods

Extrusion processes excel with thermoplastics like polyethylene, polypropylene, and PVC, enabling continuous shaping into sheets or pipes with consistent wall thickness. Blow molding mainly suits ductile polymers such as HDPE, LDPE, and PET, which soften uniformly to form hollow objects through air expansion. Material compatibility hinges on thermal stability and melt flow characteristics, dictating optimal processing parameters and final product quality in each method.

Advantages of Extrusion for Polymer Products

Extrusion offers significant advantages for polymer products, including continuous production capabilities that enhance efficiency and reduce manufacturing time. This process allows precise control over product dimensions and properties, resulting in consistent quality and material utilization. Extrusion also supports a wide range of polymer types and complex cross-sectional shapes, making it versatile for various industrial applications.

Benefits of Blow Molding in Polymer Fabrication

Blow molding in polymer fabrication offers superior ability to create hollow, seamless, and complex shapes with uniform wall thickness, which is challenging for extrusion methods. This technique enhances material efficiency by minimizing waste and enables high-volume production of lightweight, durable containers such as bottles and tanks. The versatility of blow molding supports a wide range of polymers, optimizing mechanical properties and enabling cost-effective manufacturing for diverse applications.

Typical Applications: Extrusion vs Blow Molding

Extrusion is typically used for producing continuous profiles such as pipes, sheets, and films due to its ability to create long, uniform shapes with consistent cross-sections. Blow molding is primarily applied in manufacturing hollow plastic products like bottles, containers, and fuel tanks, benefiting from its capability to form complex, lightweight, and seamless parts. Both processes serve distinct industrial needs, with extrusion suited for solid shapes and blow molding optimized for hollow, airtight designs.

Cost Factors and Production Efficiency

Extrusion offers lower initial tooling costs and faster cycle times ideal for high-volume production of continuous profiles, making it cost-effective for long runs. Blow molding incurs higher mold expenses but enables efficient production of hollow parts with reduced material waste and shorter lead times for complex shapes. Production efficiency depends on product design and volume, with extrusion favored for simple geometries and blow molding preferred for packaging applications requiring uniform wall thickness.

Choosing the Right Method for Your Polymer Product

Extrusion excels in creating continuous profiles such as pipes, sheets, and films, offering high production speeds and precise thickness control for thermoplastics like polyethylene and PVC. Blow molding is ideal for hollow objects like bottles and containers, utilizing materials such as HDPE and PET to achieve lightweight, uniform walls with complex shapes. Selecting the right process depends on product geometry, material properties, and volumetric output requirements to optimize cost-efficiency and structural integrity.

Extrusion vs Blow Molding Infographic

materialdif.com

materialdif.com