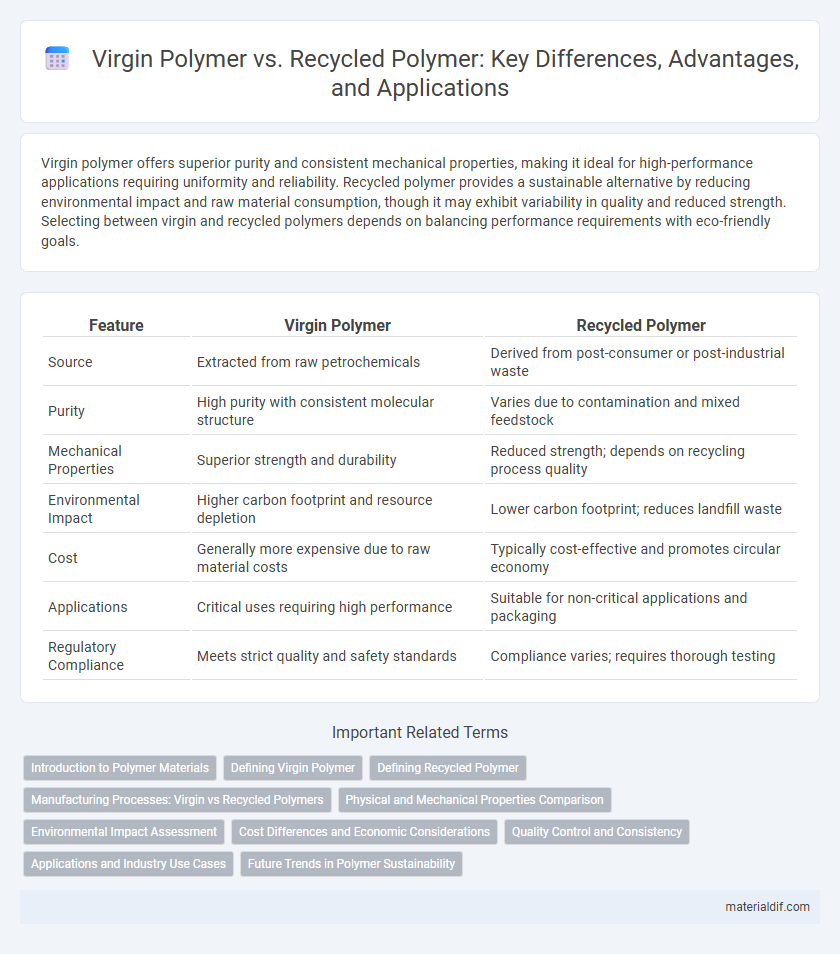

Virgin polymer offers superior purity and consistent mechanical properties, making it ideal for high-performance applications requiring uniformity and reliability. Recycled polymer provides a sustainable alternative by reducing environmental impact and raw material consumption, though it may exhibit variability in quality and reduced strength. Selecting between virgin and recycled polymers depends on balancing performance requirements with eco-friendly goals.

Table of Comparison

| Feature | Virgin Polymer | Recycled Polymer |

|---|---|---|

| Source | Extracted from raw petrochemicals | Derived from post-consumer or post-industrial waste |

| Purity | High purity with consistent molecular structure | Varies due to contamination and mixed feedstock |

| Mechanical Properties | Superior strength and durability | Reduced strength; depends on recycling process quality |

| Environmental Impact | Higher carbon footprint and resource depletion | Lower carbon footprint; reduces landfill waste |

| Cost | Generally more expensive due to raw material costs | Typically cost-effective and promotes circular economy |

| Applications | Critical uses requiring high performance | Suitable for non-critical applications and packaging |

| Regulatory Compliance | Meets strict quality and safety standards | Compliance varies; requires thorough testing |

Introduction to Polymer Materials

Virgin polymer, derived directly from petrochemical sources, offers consistent purity, mechanical strength, and predictable performance essential for high-specification applications. Recycled polymer, sourced from post-consumer or post-industrial waste, provides an eco-friendly alternative but may exhibit variability in molecular weight distribution, contamination levels, and mechanical properties. Selection between virgin and recycled polymers depends on cost-efficiency, environmental impact, and end-use performance requirements in polymer material applications.

Defining Virgin Polymer

Virgin polymer refers to plastic material produced directly from petrochemical feedstocks without prior use or processing, ensuring its purity and consistent mechanical properties. This type of polymer exhibits superior strength, clarity, and chemical resistance compared to recycled polymers, which may contain contaminants and degraded polymer chains. Virgin polymers are essential in applications demanding high performance, such as medical devices, food packaging, and automotive components.

Defining Recycled Polymer

Recycled polymer refers to plastic material that has been processed from post-consumer or post-industrial waste to create new polymer products, reducing environmental impact and conserving natural resources. Unlike virgin polymer, which is synthesized directly from raw petrochemical feedstocks, recycled polymer involves reprocessing existing plastic materials through mechanical or chemical recycling methods. This sustainable approach supports circular economy principles by minimizing plastic waste and lowering carbon emissions during manufacturing.

Manufacturing Processes: Virgin vs Recycled Polymers

Virgin polymers are produced through the polymerization of monomers derived from petrochemical resources, ensuring high purity and consistent molecular weight distribution, which results in superior mechanical and chemical properties. Recycled polymers undergo processes such as collection, sorting, cleaning, and reprocessing, often involving melting and remolding, but may exhibit variability in quality due to contamination and degradation during previous use cycles. Manufacturing recycled polymers requires advanced stabilization and compatibilizer additives to restore performance, while virgin polymer production offers predictable material characteristics without extensive post-processing.

Physical and Mechanical Properties Comparison

Virgin polymers exhibit superior physical and mechanical properties compared to recycled polymers, including higher tensile strength, better impact resistance, and greater elongation at break. Recycled polymers often show increased variability in molecular weight distribution, leading to reduced mechanical performance and potential contamination that affects consistency. Processing techniques like compatibilization can improve recycled polymer properties but generally do not reach the pristine quality of virgin materials.

Environmental Impact Assessment

Virgin polymer production generates higher carbon emissions and consumes more energy compared to recycled polymer, contributing significantly to environmental degradation. Recycled polymers reduce landfill waste, lower greenhouse gas emissions by up to 60%, and conserve non-renewable resources, making them a more sustainable choice. Life cycle assessments highlight that incorporating recycled polymers in manufacturing significantly decreases water usage and toxicity levels in comparison to virgin polymer production.

Cost Differences and Economic Considerations

Virgin polymer typically incurs higher production costs due to raw material extraction and energy-intensive processing, making it more expensive than recycled polymer. Recycled polymers benefit from reduced feedstock expenses and lower carbon footprint, translating into cost savings and increasing economic viability in circular economy models. Market demand fluctuations and quality variability influence pricing, with recycled polymers often preferred in cost-sensitive applications while virgin polymers dominate in high-performance uses.

Quality Control and Consistency

Virgin polymer offers superior quality control and consistency due to its production from raw petrochemical materials under controlled conditions, resulting in predictable properties and minimal impurities. Recycled polymer quality can vary significantly depending on the source, contamination levels, and processing methods, often requiring rigorous sorting, cleaning, and reprocessing to match virgin polymer standards. Consistency challenges in recycled polymers may affect mechanical strength, color uniformity, and thermal stability, necessitating advanced quality control measures for high-performance applications.

Applications and Industry Use Cases

Virgin polymer offers superior mechanical properties and chemical resistance, making it ideal for high-performance applications in automotive, aerospace, and medical industries. Recycled polymer finds extensive use in packaging, construction, and consumer goods, promoting sustainability and cost-efficiency while meeting regulatory standards. Both polymer types are integral to circular economy models, with recycled polymers driving innovation in eco-friendly product design.

Future Trends in Polymer Sustainability

Virgin polymers, derived directly from natural resources, offer consistent quality but pose environmental challenges due to high carbon footprints. Recycled polymers contribute to circular economy models by reducing plastic waste and lowering greenhouse gas emissions, aligning with global sustainability goals. Future trends emphasize advanced recycling technologies, such as chemical recycling and polymer blending, enhancing material performance and expanding applications in sustainable packaging and automotive industries.

Virgin Polymer vs Recycled Polymer Infographic

materialdif.com

materialdif.com