Polylactic Acid (PLA) is a biodegradable polymer derived from renewable resources, offering excellent ease of printing and environmental benefits, yet it has lower heat resistance and impact strength compared to Polycarbonate (PC). Polycarbonate is a durable, high-performance thermoplastic known for its superior toughness, heat resistance, and optical clarity but is less eco-friendly and more challenging to process. Selecting between PLA and PC depends on balancing environmental impact, mechanical properties, and application requirements.

Table of Comparison

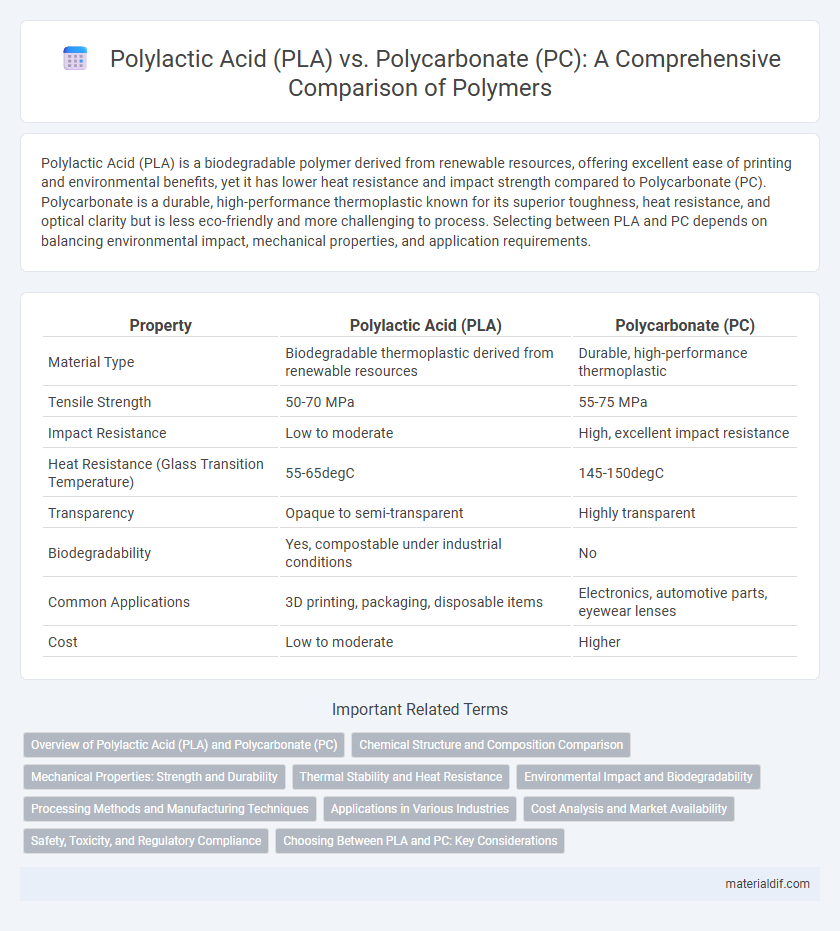

| Property | Polylactic Acid (PLA) | Polycarbonate (PC) |

|---|---|---|

| Material Type | Biodegradable thermoplastic derived from renewable resources | Durable, high-performance thermoplastic |

| Tensile Strength | 50-70 MPa | 55-75 MPa |

| Impact Resistance | Low to moderate | High, excellent impact resistance |

| Heat Resistance (Glass Transition Temperature) | 55-65degC | 145-150degC |

| Transparency | Opaque to semi-transparent | Highly transparent |

| Biodegradability | Yes, compostable under industrial conditions | No |

| Common Applications | 3D printing, packaging, disposable items | Electronics, automotive parts, eyewear lenses |

| Cost | Low to moderate | Higher |

Overview of Polylactic Acid (PLA) and Polycarbonate (PC)

Polylactic Acid (PLA) is a biodegradable thermoplastic derived from renewable resources such as corn starch or sugarcane, widely used for environmentally friendly packaging and 3D printing applications due to its compostability and ease of processing. Polycarbonate (PC) is a durable, high-performance thermoplastic known for its exceptional impact resistance, transparency, and thermal stability, making it ideal for electronic components, automotive parts, and optical lenses. PLA offers advantages in sustainability and biodegradability, while PC excels in mechanical strength and heat resistance, catering to vastly different industrial needs.

Chemical Structure and Composition Comparison

Polylactic Acid (PLA) is a biodegradable thermoplastic polymer composed primarily of lactic acid monomers linked by ester bonds, giving it a linear aliphatic polyester structure. Polycarbonate (PC), on the other hand, features a more complex aromatic polymer backbone with carbonate groups bonding bisphenol A units, resulting in enhanced thermal stability and impact resistance. The ester linkages in PLA contribute to its biodegradability, whereas the aromatic carbonate linkages in PC provide superior mechanical strength and chemical resistance.

Mechanical Properties: Strength and Durability

Polylactic Acid (PLA) exhibits high tensile strength but lower impact resistance and durability compared to Polycarbonate (PC), which offers superior toughness and impact resistance suitable for demanding mechanical applications. PC's enhanced flexibility and resistance to cracking under stress contribute to its longevity in environments requiring sustained mechanical performance. While PLA is biodegradable and works well for rigid, low-stress components, PC's strength and durability make it ideal for high-impact and load-bearing parts.

Thermal Stability and Heat Resistance

Polylactic Acid (PLA) exhibits lower thermal stability with a glass transition temperature around 60degC and melting point near 180degC, making it susceptible to deformation under high heat. Polycarbonate (PC) offers superior heat resistance, maintaining structural integrity up to 130degC and withstanding continuous use at elevated temperatures without significant degradation. This thermal advantage positions PC as the preferred choice for applications requiring high durability and resistance to heat exposure.

Environmental Impact and Biodegradability

Polylactic Acid (PLA) is derived from renewable resources like corn starch and offers biodegradability under industrial composting conditions, significantly reducing plastic waste accumulation. In contrast, Polycarbonate (PC) is petroleum-based with limited biodegradability, leading to long-term environmental persistence and reliance on fossil fuels. PLA's lower carbon footprint and compostable nature make it a more sustainable option compared to the durable but environmentally taxing PC.

Processing Methods and Manufacturing Techniques

Polylactic Acid (PLA) primarily utilizes injection molding and extrusion due to its lower melting point and biodegradability, making it suitable for applications requiring environmentally friendly processing. Polycarbonate (PC) demands higher processing temperatures and precise thermal management during injection molding and extrusion to maintain its strength and dimensional stability. Advanced manufacturing techniques like 3D printing benefit from PLA's ease of use, while PC is often preferred for components requiring superior impact resistance and heat tolerance in industrial applications.

Applications in Various Industries

Polylactic Acid (PLA) is widely used in packaging, disposable tableware, and biomedical applications due to its biodegradability and biocompatibility. Polycarbonate (PC) finds extensive use in electronics, automotive parts, and eyewear lenses for its high impact resistance and optical clarity. Both polymers serve distinct industry needs, with PLA favored for eco-friendly products and PC preferred where durability and transparency are critical.

Cost Analysis and Market Availability

Polylactic Acid (PLA) offers a cost advantage over Polycarbonate (PC) due to its bio-based production and lower raw material expenses, making it favorable for budget-sensitive applications. Polycarbonate maintains a higher market price driven by its superior impact resistance and thermal stability, limiting its use to specialized sectors like electronics and automotive. Market availability of PLA is expanding rapidly, supported by growing demand for sustainable materials, while PC remains widely available but at a relatively stable supply constrained by petrochemical feedstock volatility.

Safety, Toxicity, and Regulatory Compliance

Polylactic Acid (PLA) is a biodegradable polymer commonly derived from renewable resources like corn starch, exhibiting low toxicity and generally recognized as safe (GRAS) for food contact applications under FDA and EU regulations. Polycarbonate (PC), a durable thermoplastic known for impact resistance, contains bisphenol A (BPA), raising concerns about potential endocrine disruption and stricter regulatory scrutiny by agencies such as the European Chemicals Agency (ECHA). Safety considerations favor PLA in contexts requiring biocompatibility and minimal chemical leaching, while PC's regulatory compliance demands careful assessment of BPA migration limits and usage conditions.

Choosing Between PLA and PC: Key Considerations

Choosing between Polylactic Acid (PLA) and Polycarbonate (PC) involves evaluating factors such as mechanical strength, heat resistance, and environmental impact. PLA, a biodegradable polymer derived from renewable resources, is ideal for applications requiring eco-friendly and easy-to-process materials but lacks high-temperature durability and impact resistance. In contrast, PC offers superior toughness, high heat deflection temperature, and excellent dimensional stability, making it suitable for more demanding engineering applications despite its non-biodegradable nature.

Polylactic Acid (PLA) vs Polycarbonate (PC) Infographic

materialdif.com

materialdif.com