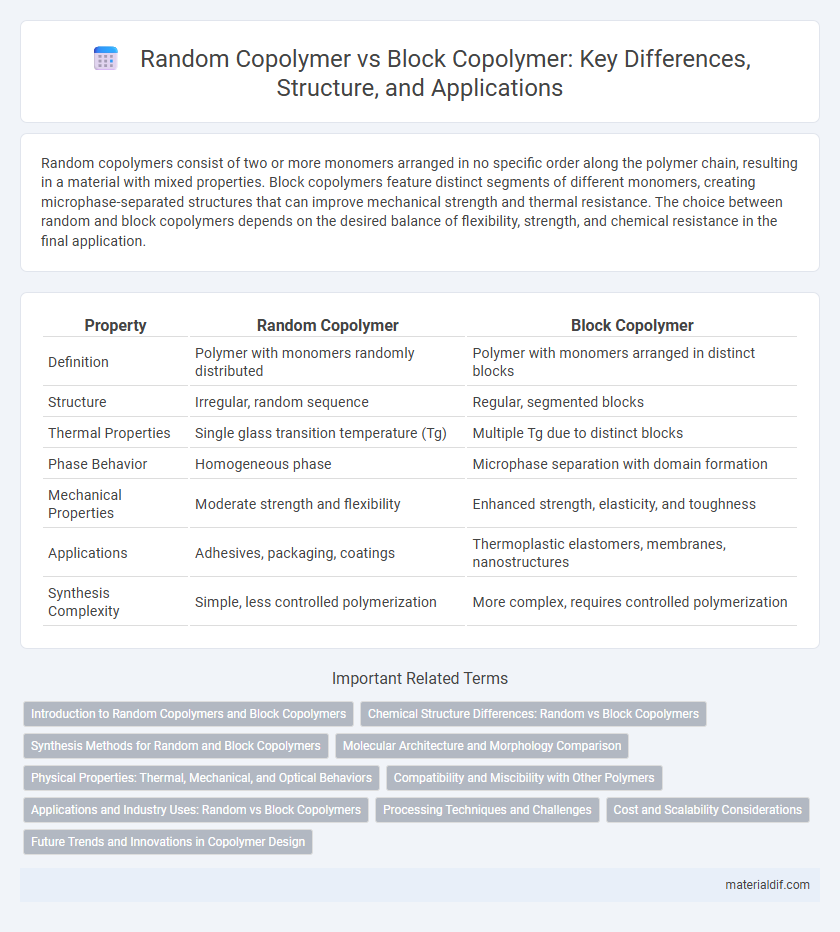

Random copolymers consist of two or more monomers arranged in no specific order along the polymer chain, resulting in a material with mixed properties. Block copolymers feature distinct segments of different monomers, creating microphase-separated structures that can improve mechanical strength and thermal resistance. The choice between random and block copolymers depends on the desired balance of flexibility, strength, and chemical resistance in the final application.

Table of Comparison

| Property | Random Copolymer | Block Copolymer |

|---|---|---|

| Definition | Polymer with monomers randomly distributed | Polymer with monomers arranged in distinct blocks |

| Structure | Irregular, random sequence | Regular, segmented blocks |

| Thermal Properties | Single glass transition temperature (Tg) | Multiple Tg due to distinct blocks |

| Phase Behavior | Homogeneous phase | Microphase separation with domain formation |

| Mechanical Properties | Moderate strength and flexibility | Enhanced strength, elasticity, and toughness |

| Applications | Adhesives, packaging, coatings | Thermoplastic elastomers, membranes, nanostructures |

| Synthesis Complexity | Simple, less controlled polymerization | More complex, requires controlled polymerization |

Introduction to Random Copolymers and Block Copolymers

Random copolymers consist of two or more monomer units distributed randomly along the polymer chain, resulting in properties that reflect an averaged behavior of all monomers. Block copolymers contain distinct segments or "blocks" of alternating monomers, creating microphase-separated domains that influence mechanical strength, thermal resistance, and self-assembling capabilities. The structural arrangement in block copolymers enables tunable material characteristics, contrasting with the more homogeneous properties of random copolymers.

Chemical Structure Differences: Random vs Block Copolymers

Random copolymers consist of two or more monomers arranged in a random sequence along the polymer chain, resulting in a heterogeneous chemical structure. Block copolymers feature distinct blocks of repeating units from each monomer, forming well-defined segments within the polymer. The chemical structure differences lead to variations in physical properties and phase behavior between random and block copolymers.

Synthesis Methods for Random and Block Copolymers

Random copolymers are typically synthesized through free radical or ionic copolymerization, where monomers are incorporated in a statistically random sequence along the polymer chain. Block copolymers are produced via controlled/living polymerization techniques such as atom transfer radical polymerization (ATRP), reversible addition-fragmentation chain transfer (RAFT), or anionic polymerization, enabling the formation of well-defined polymer blocks with distinct compositions. The precision in block copolymer synthesis allows tailoring of molecular architecture, whereas random copolymer synthesis favors simpler, less controlled polymer chain formation.

Molecular Architecture and Morphology Comparison

Random copolymers consist of monomer units distributed irregularly along the polymer chain, resulting in a more homogeneous morphology with less phase separation at the molecular level. Block copolymers feature distinct blocks of different monomers arranged sequentially, leading to microphase-separated structures that form well-defined domains such as lamellae, cylinders, or spheres, enhancing material properties. The molecular architecture of block copolymers promotes organized morphologies that can be precisely tuned for applications requiring nanoscale phase separation, unlike the more amorphous structures seen in random copolymers.

Physical Properties: Thermal, Mechanical, and Optical Behaviors

Random copolymers exhibit more amorphous structures leading to lower melting points and glass transition temperatures compared to block copolymers, which possess distinct phase-separated domains enhancing thermal stability. Mechanically, block copolymers demonstrate superior strength and elasticity due to microphase separation providing reinforcement, whereas random copolymers offer more uniform but generally lower mechanical properties. Optically, block copolymers can exhibit anisotropic behavior and increased clarity linked to their ordered domains, while random copolymers tend to have isotropic optical properties with less transparency.

Compatibility and Miscibility with Other Polymers

Random copolymers exhibit enhanced compatibility and miscibility with diverse polymer matrices due to their irregular monomer distribution, which disrupts crystallinity and reduces phase separation. Block copolymers, characterized by distinct polymer blocks, demonstrate microphase separation that can lead to unique nanostructures but may limit miscibility with incompatible polymers. The tailored block length and composition in block copolymers allow controlled self-assembly, influencing interfacial properties and compatibility in polymer blends.

Applications and Industry Uses: Random vs Block Copolymers

Random copolymers are widely used in packaging, adhesives, and automotive industries due to their enhanced toughness and uniform properties, making them suitable for flexible films and impact-resistant materials. Block copolymers are prevalent in high-performance applications such as thermoplastic elastomers, medical devices, and nanotechnology, where distinct phase-separated domains provide superior mechanical strength and elasticity. Industries leverage block copolymers for advanced coatings and drug delivery systems, while random copolymers are favored for cost-effective mass production and consistent material behavior.

Processing Techniques and Challenges

Random copolymers exhibit a more uniform distribution of monomer units, which facilitates easier processing techniques such as injection molding and extrusion due to their consistent melting properties. In contrast, block copolymers present challenges in processing because of their phase-separated microstructures, requiring precise temperature control during techniques like melt processing and solvent casting to achieve desired mechanical properties. Optimizing processing parameters for block copolymers is critical to managing microphase separation and preventing defects such as voids or inhomogeneities.

Cost and Scalability Considerations

Random copolymers generally offer lower production costs and higher scalability due to simpler synthesis processes and fewer reaction steps compared to block copolymers. Block copolymers require precise control over polymerization conditions, increasing manufacturing complexity and cost, which can limit large-scale production. The trade-off between material performance and cost efficiency influences the choice between random and block copolymers in industrial applications.

Future Trends and Innovations in Copolymer Design

Future trends in copolymer design emphasize enhanced functionality through precise control of polymer architecture, enabling tailored properties for specific applications such as drug delivery and nanotechnology. Innovations in random copolymer synthesis focus on exploiting stochastic monomer distribution to achieve tunable thermal stability and mechanical strength. Block copolymer research advances with novel self-assembly techniques and programmable sequences to create smart materials and responsive surfaces for next-generation devices.

Random Copolymer vs Block Copolymer Infographic

materialdif.com

materialdif.com