Elastomers exhibit high elasticity and flexibility, making them ideal for applications requiring stretch and recovery, while rigid polymers provide structural strength and dimensional stability. The molecular structure of elastomers consists of loosely cross-linked chains that allow deformation without permanent shape change. In contrast, rigid polymers have tightly packed chains with strong intermolecular forces, resulting in hardness and resistance to deformation.

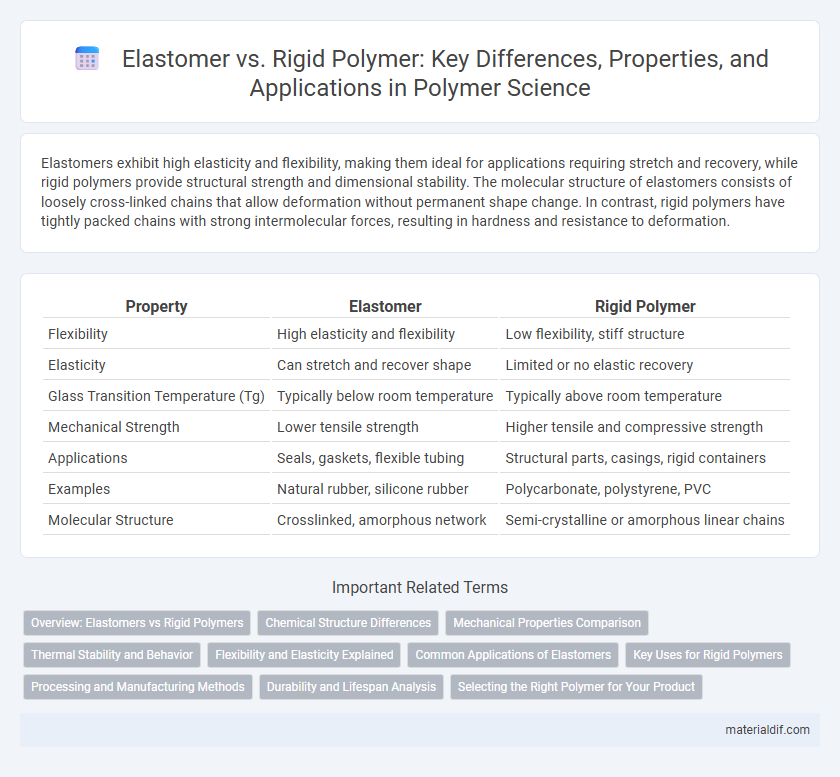

Table of Comparison

| Property | Elastomer | Rigid Polymer |

|---|---|---|

| Flexibility | High elasticity and flexibility | Low flexibility, stiff structure |

| Elasticity | Can stretch and recover shape | Limited or no elastic recovery |

| Glass Transition Temperature (Tg) | Typically below room temperature | Typically above room temperature |

| Mechanical Strength | Lower tensile strength | Higher tensile and compressive strength |

| Applications | Seals, gaskets, flexible tubing | Structural parts, casings, rigid containers |

| Examples | Natural rubber, silicone rubber | Polycarbonate, polystyrene, PVC |

| Molecular Structure | Crosslinked, amorphous network | Semi-crystalline or amorphous linear chains |

Overview: Elastomers vs Rigid Polymers

Elastomers are polymers characterized by their high elasticity and ability to undergo significant reversible deformation, making them ideal for applications requiring flexibility and resilience. Rigid polymers, in contrast, possess a high degree of stiffness and strength due to their tightly packed molecular chains, offering excellent dimensional stability and mechanical resistance. The key distinction lies in the molecular structure and cross-linking density, which governs whether the polymer exhibits elastic or rigid behavior.

Chemical Structure Differences

Elastomers possess long, flexible polymer chains with low cross-link density, allowing extensive elastic deformation under stress. In contrast, rigid polymers have tightly packed, highly cross-linked or crystalline structures that restrict chain mobility, resulting in stiffness and minimal elongation. The chemical backbone of elastomers often contains flexible segments like carbon-carbon single bonds, whereas rigid polymers feature aromatic rings or strong intermolecular forces that enhance rigidity.

Mechanical Properties Comparison

Elastomers exhibit high elasticity and flexibility, enabling them to undergo significant deformation and recover their original shape, characterized by low modulus and high elongation at break. In contrast, rigid polymers possess high stiffness and tensile strength, with a high modulus and limited elongation, resulting in brittle failure under stress. The mechanical performance differences stem from the molecular structure, where elastomers have loosely cross-linked networks and flexible chains, while rigid polymers feature tightly packed, crystalline or amorphous regions restricting molecular mobility.

Thermal Stability and Behavior

Elastomers exhibit superior thermal flexibility, maintaining elasticity over a broad temperature range, whereas rigid polymers demonstrate higher thermal stability with resistance to deformation under heat. The glass transition temperature (Tg) of elastomers is significantly lower, allowing them to remain rubbery, while rigid polymers have higher Tg values that make them more dimensionally stable but brittle at elevated temperatures. Thermal degradation in elastomers occurs at lower temperatures compared to rigid polymers, influencing their applications in high-heat environments.

Flexibility and Elasticity Explained

Elastomers are polymers characterized by their exceptional flexibility and high elasticity, enabling them to stretch significantly and return to their original shape without permanent deformation. Rigid polymers exhibit limited flexibility due to their tightly packed molecular structures, resulting in lower elasticity and more brittle behavior under stress. The key difference lies in the molecular arrangement and cross-linking density, which governs the flexibility and elastic recovery of these materials.

Common Applications of Elastomers

Elastomers are widely used in automotive parts such as tires, seals, and gaskets due to their exceptional elasticity and resistance to deformation. They also find applications in medical devices like flexible tubing and gloves, benefiting from their biocompatibility and flexibility. Consumer products including footwear soles and sports equipment rely on elastomers for durability and comfort, contrasting with rigid polymers that are usually preferred in structural components.

Key Uses for Rigid Polymers

Rigid polymers are crucial in applications requiring structural strength and durability, such as automotive components, construction materials, and electronic housings. Their high stiffness and resistance to deformation make them ideal for load-bearing parts and dimensional stability in precision instruments. These polymers are commonly used in manufacturing rigid containers, piping systems, and equipment casings where impact resistance and rigidity are essential.

Processing and Manufacturing Methods

Elastomers typically undergo vulcanization or curing processes that enhance their elasticity and resilience, making them suitable for molding, extrusion, and calendering techniques. In contrast, rigid polymers are often processed through injection molding, blow molding, or thermoforming, which require higher temperatures and precise control to maintain structural integrity. Manufacturing methods for elastomers emphasize flexibility and elongation properties, whereas rigid polymers focus on rigidity and dimensional stability during production.

Durability and Lifespan Analysis

Elastomers exhibit superior flexibility and impact resistance, contributing to enhanced durability in dynamic applications compared to rigid polymers, which offer higher structural strength but are more prone to brittle failure. The molecular architecture of elastomers, characterized by flexible cross-linked chains, enables better energy absorption and resilience, extending their lifespan under cyclic stress conditions. In contrast, rigid polymers, with their densely packed, crystalline regions, typically experience shorter service lives when subjected to mechanical fatigue or environmental stressors.

Selecting the Right Polymer for Your Product

Elastomers exhibit high elasticity and flexibility, making them ideal for products requiring impact resistance and stretchability, such as seals and flexible molds. Rigid polymers offer superior structural strength and dimensional stability, suited for applications like automotive parts and electronic housings. Selecting the right polymer depends on balancing mechanical requirements, environmental exposure, and processing methods to ensure product performance and durability.

Elastomer vs Rigid Polymer Infographic

materialdif.com

materialdif.com