Monomeric polyethylene, derived from a single type of ethylene monomer, offers consistent polymer structure and is commonly used for applications requiring uniform density and strength. Copolymeric polyethylene incorporates different monomers, such as butene or hexene, enhancing flexibility, impact resistance, and clarity, making it ideal for films and packaging. The choice between monomeric and copolymeric polyethylene depends on specific performance requirements, including tensile strength, elasticity, and environmental stress resistance.

Table of Comparison

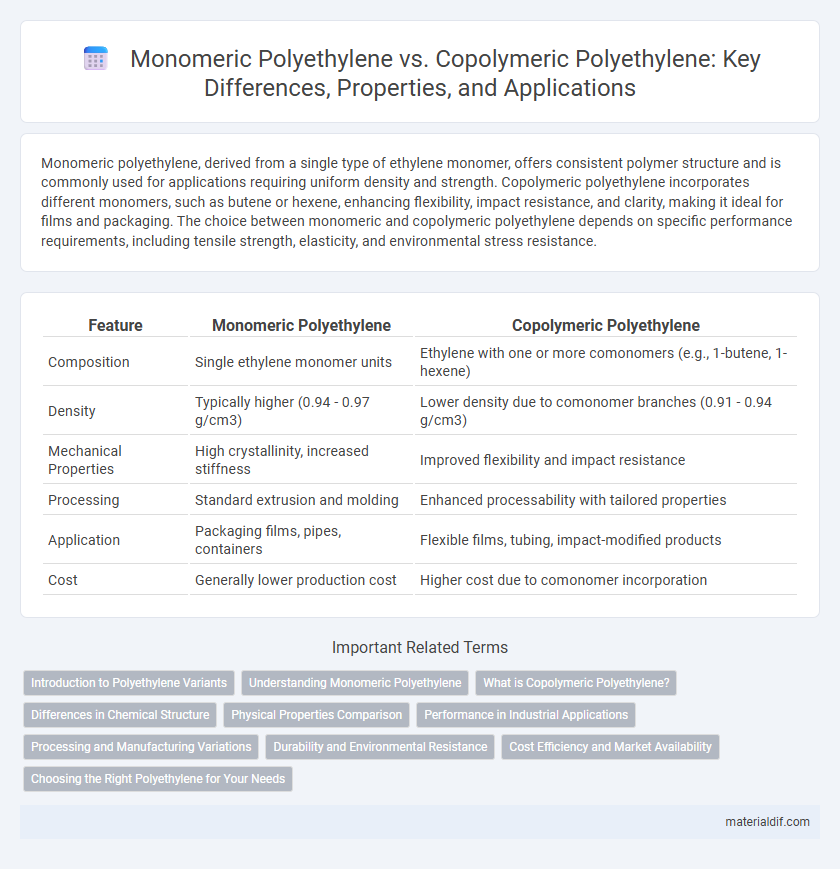

| Feature | Monomeric Polyethylene | Copolymeric Polyethylene |

|---|---|---|

| Composition | Single ethylene monomer units | Ethylene with one or more comonomers (e.g., 1-butene, 1-hexene) |

| Density | Typically higher (0.94 - 0.97 g/cm3) | Lower density due to comonomer branches (0.91 - 0.94 g/cm3) |

| Mechanical Properties | High crystallinity, increased stiffness | Improved flexibility and impact resistance |

| Processing | Standard extrusion and molding | Enhanced processability with tailored properties |

| Application | Packaging films, pipes, containers | Flexible films, tubing, impact-modified products |

| Cost | Generally lower production cost | Higher cost due to comonomer incorporation |

Introduction to Polyethylene Variants

Monomeric polyethylene consists of polymer chains derived from a single type of monomer, typically ethylene, resulting in a uniform molecular structure with high crystallinity and density. Copolymeric polyethylene incorporates different comonomers such as butene, hexene, or octene, which modify the polymer architecture to enhance properties like flexibility, toughness, and impact resistance. These variants influence the material's applications, with monomeric polyethylene often used in rigid packaging, while copolymeric types are preferred for flexible films and elastomeric products.

Understanding Monomeric Polyethylene

Monomeric polyethylene is synthesized from a single type of ethylene monomer, resulting in a uniform polymer chain with consistent molecular structure and properties such as high crystallinity and chemical resistance. Unlike copolymeric polyethylene, which incorporates different monomers to modify flexibility or impact strength, monomeric polyethylene typically exhibits higher tensile strength and density. Understanding its molecular weight distribution and chain branching is crucial for applications requiring rigidity, durability, and excellent barrier performance in packaging and industrial materials.

What is Copolymeric Polyethylene?

Copolymeric polyethylene is a type of polyethylene synthesized by polymerizing two or more different monomers, typically ethylene combined with other alpha-olefins like butene, hexene, or octene. This copolymerization process enhances material properties such as flexibility, toughness, and impact resistance compared to monomeric polyethylene, which is made solely from ethylene. Common applications of copolymeric polyethylene include packaging films, automotive parts, and piping systems due to its improved mechanical performance and durability.

Differences in Chemical Structure

Monomeric polyethylene consists solely of ethylene monomers polymerized into long chains, resulting in a uniform chemical structure characterized by repeating -CH2- units. Copolymeric polyethylene incorporates other monomers such as alpha-olefins (e.g., 1-butene, 1-hexene) into the polymer chain, introducing branches and variations in the chemical backbone. This structural difference affects properties like density, crystallinity, and flexibility, distinguishing monomeric high-density polyethylene (HDPE) from copolymeric linear low-density polyethylene (LLDPE).

Physical Properties Comparison

Monomeric polyethylene, primarily composed of ethylene units, exhibits higher crystallinity, resulting in greater density, tensile strength, and stiffness compared to copolymeric polyethylene, which incorporates comonomers like butene or hexene to disrupt regular packing. Copolymeric polyethylene demonstrates improved flexibility, impact resistance, and clarity due to its lower crystallinity and amorphous regions. The physical properties of monomeric polyethylene favor applications requiring rigidity and chemical resistance, while copolymeric variants suit uses demanding toughness and ductility.

Performance in Industrial Applications

Monomeric polyethylene, produced from a single ethylene monomer, offers high crystallinity and superior tensile strength, making it ideal for applications requiring rigidity and chemical resistance. Copolymeric polyethylene, synthesized with comonomers such as butene or hexene, enhances flexibility, impact resistance, and low-temperature performance, which is crucial in applications like automotive parts and flexible packaging. Industrial performance differences primarily hinge on mechanical properties and environmental stress resistance, influencing material selection based on specific operational demands.

Processing and Manufacturing Variations

Monomeric polyethylene is produced from the polymerization of a single monomer, ethylene, resulting in a simpler manufacturing process with consistent molecular structure that facilitates easier processing and predictable melting points. Copolymeric polyethylene involves the polymerization of ethylene with other monomers such as vinyl acetate or acrylic acid, creating materials with tailored properties like enhanced flexibility or impact resistance but requiring more complex processing conditions to manage diverse chain structures. The manufacturing variations impact extrusion, molding, and film-blowing techniques, where monomeric polyethylene offers uniformity and copolymeric grades demand adjusted temperatures and catalysts for optimal polymerization control.

Durability and Environmental Resistance

Monomeric polyethylene, made from a single type of ethylene monomer, offers high crystallinity which enhances its durability and resistance to chemical degradation. Copolymeric polyethylene incorporates different monomers, resulting in lower crystallinity but improved flexibility and impact resistance, which benefits performance under varying environmental conditions. Both types exhibit strong environmental resistance, though copolymeric variants generally show better resistance to stress cracking and UV exposure due to their altered molecular structure.

Cost Efficiency and Market Availability

Monomeric polyethylene, derived solely from ethylene monomers, offers higher cost efficiency due to simpler production processes and lower raw material expenses, making it widely available in global markets. Copolymeric polyethylene incorporates comonomers like butene or hexene to enhance material properties but results in increased manufacturing complexity and higher costs, limiting its market availability compared to monomeric variants. Both types serve distinct applications; however, monomeric polyethylene dominates demand for cost-sensitive uses, while copolymeric forms target niche markets requiring superior performance.

Choosing the Right Polyethylene for Your Needs

Monomeric polyethylene, derived from a single type of monomer such as ethylene, offers uniform molecular structure ideal for applications requiring consistent mechanical properties and chemical resistance. Copolymeric polyethylene incorporates different monomers, enhancing flexibility, impact strength, and environmental stress crack resistance, making it suitable for more demanding or specialized uses. Selecting the right polyethylene depends on balancing desired durability, flexibility, and chemical compatibility with the specific performance criteria of your project or product.

Monomeric Polyethylene vs Copolymeric Polyethylene Infographic

materialdif.com

materialdif.com