Halogenated polyethylene contains halogen atoms such as chlorine or bromine, which enhance its flame retardant properties and chemical resistance compared to non-halogenated polyethylene. Non-halogenated polyethylene, lacking these halogen atoms, offers better environmental friendliness and lower toxicity, making it suitable for applications requiring high safety standards. Choosing between halogenated and non-halogenated polyethylene depends on the specific performance requirements and regulatory constraints of the intended use.

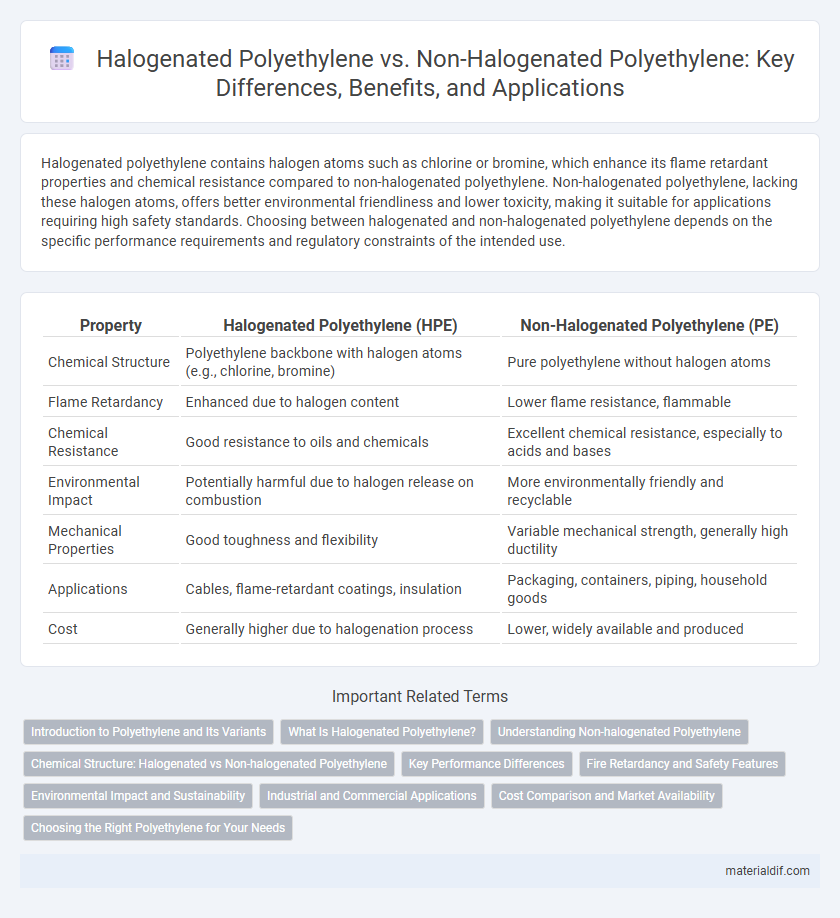

Table of Comparison

| Property | Halogenated Polyethylene (HPE) | Non-Halogenated Polyethylene (PE) |

|---|---|---|

| Chemical Structure | Polyethylene backbone with halogen atoms (e.g., chlorine, bromine) | Pure polyethylene without halogen atoms |

| Flame Retardancy | Enhanced due to halogen content | Lower flame resistance, flammable |

| Chemical Resistance | Good resistance to oils and chemicals | Excellent chemical resistance, especially to acids and bases |

| Environmental Impact | Potentially harmful due to halogen release on combustion | More environmentally friendly and recyclable |

| Mechanical Properties | Good toughness and flexibility | Variable mechanical strength, generally high ductility |

| Applications | Cables, flame-retardant coatings, insulation | Packaging, containers, piping, household goods |

| Cost | Generally higher due to halogenation process | Lower, widely available and produced |

Introduction to Polyethylene and Its Variants

Polyethylene, a versatile thermoplastic polymer, is widely used in packaging, insulation, and automotive industries due to its durability and chemical resistance. Halogenated polyethylene incorporates halogen atoms such as chlorine or bromine, enhancing flame retardancy and chemical stability compared to the non-halogenated variant, which offers superior flexibility and environmental compatibility. The choice between halogenated and non-halogenated polyethylene depends on application-specific requirements like fire safety standards and environmental impact considerations.

What Is Halogenated Polyethylene?

Halogenated polyethylene (HPE) is a modified form of polyethylene in which halogen atoms, such as chlorine or bromine, are chemically incorporated into the polymer chain to enhance properties like flame retardancy and chemical resistance. This halogenation process increases thermal stability and reduces flammability, making HPE suitable for applications requiring improved safety standards compared to non-halogenated polyethylene. Unlike standard polyethylene, non-halogenated variants lack these halogen atoms, resulting in lower fire resistance but often improved environmental and electrical insulation characteristics.

Understanding Non-halogenated Polyethylene

Non-halogenated polyethylene is a type of polyethylene polymer free from halogen atoms such as chlorine or bromine, offering superior environmental safety and reduced toxicity compared to halogenated variants. It exhibits excellent chemical resistance, electrical insulation, and durability, making it ideal for packaging, automotive parts, and electrical applications. The absence of halogens also enhances its recyclability and lowers the release of harmful gases during combustion.

Chemical Structure: Halogenated vs Non-halogenated Polyethylene

Halogenated polyethylene contains halogen atoms such as chlorine or bromine chemically bonded to the polyethylene chain, altering its chemical structure and enhancing flame retardancy and chemical resistance. Non-halogenated polyethylene consists solely of carbon and hydrogen atoms arranged in a linear or branched polymer chain, offering excellent chemical stability and environmental friendliness. The presence of halogen atoms in halogenated polyethylene introduces increased polarity and reactivity compared to the non-halogenated counterpart.

Key Performance Differences

Halogenated polyethylene offers superior flame retardancy and chemical resistance compared to non-halogenated polyethylene, making it ideal for applications requiring enhanced safety standards. Non-halogenated polyethylene excels in environmental friendliness, with lower toxicity and better recyclability, aligning with sustainable manufacturing goals. Mechanical properties such as tensile strength and flexibility remain comparable, but halogenated variants demonstrate improved thermal stability under high-heat conditions.

Fire Retardancy and Safety Features

Halogenated polyethylene exhibits superior fire retardancy due to the presence of halogen atoms, which inhibit flame propagation by releasing halogen radicals that quench combustion reactions. Non-halogenated polyethylene, while generally safer for human health and the environment due to the absence of toxic halogen compounds, has inherently lower fire resistance and requires the addition of non-halogen flame retardants to improve safety. The choice between halogenated and non-halogenated polyethylene balances enhanced fire safety performance against environmental and health considerations.

Environmental Impact and Sustainability

Halogenated polyethylene contains halogens such as chlorine or bromine, which can release toxic and persistent compounds during production and disposal, posing significant environmental challenges. Non-halogenated polyethylene offers improved sustainability due to its more straightforward recycling processes and reduced risk of harmful emissions when incinerated. Life cycle assessments show non-halogenated variants often have a lower carbon footprint and better compatibility with circular economy initiatives.

Industrial and Commercial Applications

Halogenated polyethylene offers enhanced flame retardancy and chemical resistance, making it suitable for demanding industrial applications such as cable insulation, automotive components, and protective coatings where safety standards are stringent. Non-halogenated polyethylene is preferred in commercial packaging, consumer goods, and food contact materials due to its environmental friendliness and ease of recycling. Both variants support diverse industries by balancing performance requirements with regulatory compliance and sustainability goals.

Cost Comparison and Market Availability

Halogenated polyethylene generally incurs higher production costs due to additional chemical processing steps, resulting in increased market prices compared to non-halogenated polyethylene. Non-halogenated polyethylene benefits from widespread availability and lower raw material expenses, making it more cost-effective for large-scale industrial applications. Market demand favors non-halogenated variants due to their affordability and easier compliance with environmental regulations.

Choosing the Right Polyethylene for Your Needs

Halogenated polyethylene offers enhanced flame retardancy and chemical resistance, making it ideal for applications requiring stringent fire safety standards or exposure to harsh chemicals. Non-halogenated polyethylene provides superior environmental compatibility and mechanical properties, favored in packaging and consumer goods where sustainability and flexibility are critical. Selecting between halogenated and non-halogenated polyethylene depends on specific performance requirements such as fire resistance, chemical exposure, and environmental impact.

Halogenated Polyethylene vs Non-halogenated Polyethylene Infographic

materialdif.com

materialdif.com