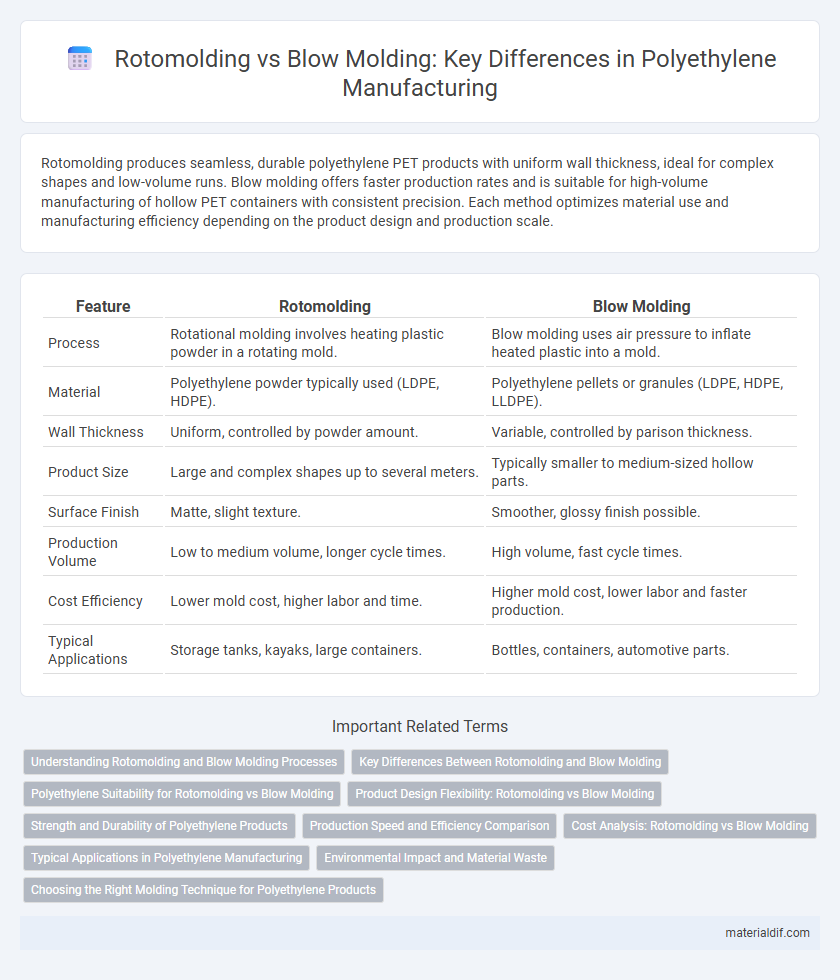

Rotomolding produces seamless, durable polyethylene PET products with uniform wall thickness, ideal for complex shapes and low-volume runs. Blow molding offers faster production rates and is suitable for high-volume manufacturing of hollow PET containers with consistent precision. Each method optimizes material use and manufacturing efficiency depending on the product design and production scale.

Table of Comparison

| Feature | Rotomolding | Blow Molding |

|---|---|---|

| Process | Rotational molding involves heating plastic powder in a rotating mold. | Blow molding uses air pressure to inflate heated plastic into a mold. |

| Material | Polyethylene powder typically used (LDPE, HDPE). | Polyethylene pellets or granules (LDPE, HDPE, LLDPE). |

| Wall Thickness | Uniform, controlled by powder amount. | Variable, controlled by parison thickness. |

| Product Size | Large and complex shapes up to several meters. | Typically smaller to medium-sized hollow parts. |

| Surface Finish | Matte, slight texture. | Smoother, glossy finish possible. |

| Production Volume | Low to medium volume, longer cycle times. | High volume, fast cycle times. |

| Cost Efficiency | Lower mold cost, higher labor and time. | Higher mold cost, lower labor and faster production. |

| Typical Applications | Storage tanks, kayaks, large containers. | Bottles, containers, automotive parts. |

Understanding Rotomolding and Blow Molding Processes

Rotomolding, or rotational molding, involves heating a hollow mold filled with polyethylene resin while rotating it along multiple axes to create seamless, hollow parts, ideal for large, complex shapes with uniform wall thickness. Blow molding uses heated polyethylene to form a parison, which is inflated inside a mold to produce hollow objects, commonly bottles and containers with precise, thinner walls. Both methods leverage polyethylene's thermoplastic properties but differ in mold complexity, part design, and production volume suitability.

Key Differences Between Rotomolding and Blow Molding

Rotomolding uses slow, rotational heating to create hollow, stress-free polyethylene products with uniform wall thickness, ideal for large, complex shapes. Blow molding involves inflating heated polyethylene parisons into molds, producing high-volume, thin-walled containers such as bottles with faster cycle times. Key differences include wall thickness control, production volume, part size, and mold complexity, making rotomolding suited for durable, low-volume items and blow molding for high-speed manufacturing of lightweight containers.

Polyethylene Suitability for Rotomolding vs Blow Molding

Polyethylene exhibits excellent suitability for rotomolding due to its low melting point and ability to form seamless, uniform wall thickness in large, hollow objects. In blow molding, polyethylene's high melt strength is ideal for creating thin-walled containers with complex shapes, but it may result in less uniformity compared to rotomolding. The molecular structure of polyethylene allows rotomolding to produce durable, stress-resistant items, while blow molding is preferred for high-volume, lightweight packaging applications.

Product Design Flexibility: Rotomolding vs Blow Molding

Rotomolding offers superior product design flexibility compared to blow molding, enabling the creation of complex, hollow shapes with uniform wall thickness and intricate details. Blow molding excels in high-volume production of lightweight, hollow containers but is limited in design complexity and wall thickness variation. The ability of rotomolding to handle thick, multi-layered parts and integrate inserts provides enhanced customization options for specialized polyethylene products.

Strength and Durability of Polyethylene Products

Rotomolding produces polyethylene products with uniform wall thickness, enhancing impact resistance and durability, making them ideal for heavy-duty applications. Blow molding offers faster production but often results in thinner walls, which may reduce overall strength compared to rotomolded items. The superior molecular distribution in rotomolded polyethylene contributes to increased toughness and longer lifespan under stress and environmental exposure.

Production Speed and Efficiency Comparison

Rotomolding offers slower production speeds compared to blow molding due to its cyclical heating and cooling phases, limiting output volume. Blow molding excels in efficiency with rapid cycle times and automation, enabling high-volume manufacturing of hollow polyethylene products. The choice depends on balancing rotomolding's capability for complex shapes against blow molding's demand for faster, large-scale polyethylene production.

Cost Analysis: Rotomolding vs Blow Molding

Rotomolding typically involves lower tooling costs compared to blow molding, making it cost-effective for small to medium production runs and complex shapes with uniform wall thickness. Blow molding requires more expensive molds and higher setup costs but offers faster production rates and efficiency for large-scale manufacturing of hollow polyethylene products. The choice between rotomolding and blow molding for polyethylene depends on balancing initial investment against volume requirements and design complexity.

Typical Applications in Polyethylene Manufacturing

Rotomolding is widely used for producing large, hollow polyethylene products such as tanks, containers, and playground equipment due to its ability to create uniform wall thickness and complex shapes. Blow molding is preferred for manufacturing hollow polyethylene bottles, containers, and drums that require high precision and rapid production cycles. Both processes leverage polyethylene's flexibility and chemical resistance, optimizing cost-efficiency across various industrial and consumer applications.

Environmental Impact and Material Waste

Rotomolding produces less material waste compared to blow molding, as it uses precise amounts of polyethylene powder with minimal scrap generation. Blow molding often results in higher scrap rates due to trimming and defective parts, contributing to increased environmental impact through waste and energy consumption. Rotomolding's slower cooling process also reduces internal stresses, enhancing product durability and extending lifecycle sustainability.

Choosing the Right Molding Technique for Polyethylene Products

Rotomolding offers uniform wall thickness and excellent stress distribution for large, hollow polyethylene products, making it ideal for tanks, containers, and complex shapes. Blow molding provides faster production cycles and is better suited for creating lightweight, thin-walled polyethylene bottles and packaging with high volume output. Selecting the right molding technique depends on product size, production volume, and performance requirements specific to polyethylene applications.

Rotomolding vs Blow Molding Infographic

materialdif.com

materialdif.com