Monomer migration in polyethylene PET primarily involves the movement of unreacted ethylene and terephthalic acid units from the polymer matrix into the surrounding environment, potentially impacting product safety and quality. Additive leaching refers to the release of intentionally added substances such as plasticizers, stabilizers, or antioxidants, which can affect the polymer's performance and pose health concerns. Understanding the differing mechanisms of monomer migration and additive leaching is essential for improving PET packaging design and ensuring regulatory compliance.

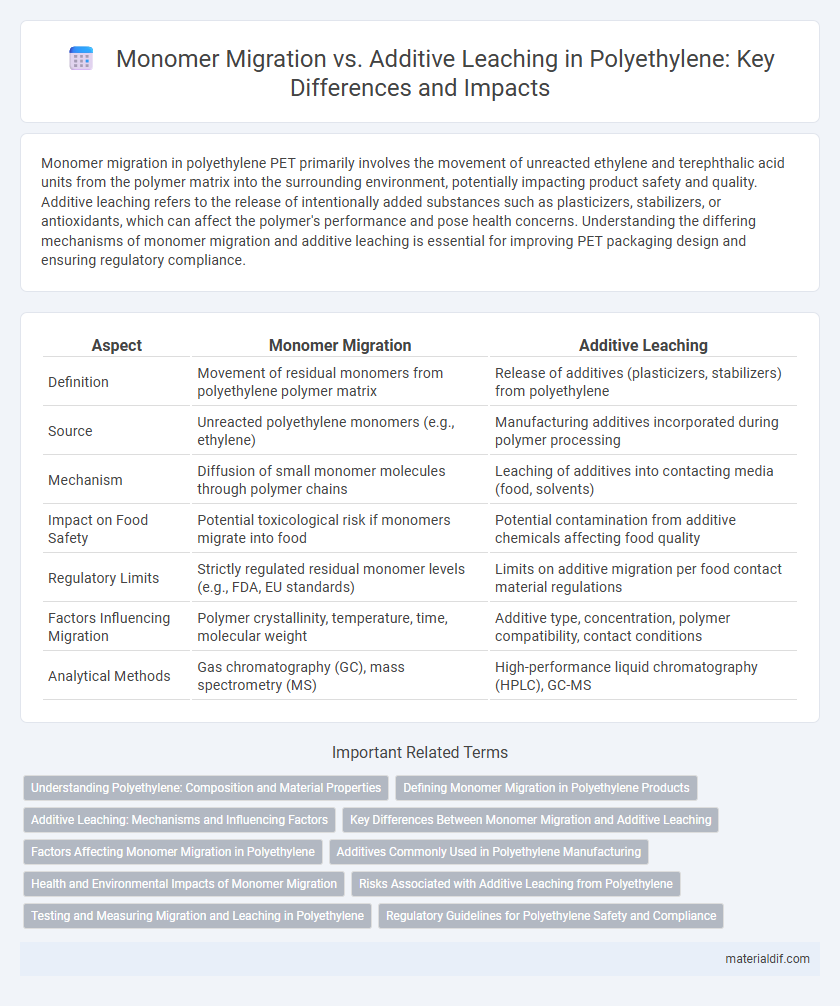

Table of Comparison

| Aspect | Monomer Migration | Additive Leaching |

|---|---|---|

| Definition | Movement of residual monomers from polyethylene polymer matrix | Release of additives (plasticizers, stabilizers) from polyethylene |

| Source | Unreacted polyethylene monomers (e.g., ethylene) | Manufacturing additives incorporated during polymer processing |

| Mechanism | Diffusion of small monomer molecules through polymer chains | Leaching of additives into contacting media (food, solvents) |

| Impact on Food Safety | Potential toxicological risk if monomers migrate into food | Potential contamination from additive chemicals affecting food quality |

| Regulatory Limits | Strictly regulated residual monomer levels (e.g., FDA, EU standards) | Limits on additive migration per food contact material regulations |

| Factors Influencing Migration | Polymer crystallinity, temperature, time, molecular weight | Additive type, concentration, polymer compatibility, contact conditions |

| Analytical Methods | Gas chromatography (GC), mass spectrometry (MS) | High-performance liquid chromatography (HPLC), GC-MS |

Understanding Polyethylene: Composition and Material Properties

Monomer migration in polyethylene primarily involves the movement of residual ethylene monomers trapped during polymerization, which can influence the polymer's purity and safety. Additive leaching refers to the release of stabilizers, antioxidants, plasticizers, or fillers incorporated to enhance polyethylene's flexibility, durability, and UV resistance, impacting long-term material performance. Understanding the distinction between monomer migration and additive leaching is crucial for assessing polyethylene's chemical stability, environmental impact, and suitability for food packaging or medical applications.

Defining Monomer Migration in Polyethylene Products

Monomer migration in polyethylene products refers to the diffusion of unreacted ethylene monomers from the polymer matrix into the surrounding environment, potentially affecting product safety and performance. This phenomenon differs from additive leaching, where intentionally added substances such as antioxidants or plasticizers migrate out of the polyethylene. Understanding monomer migration is critical for regulatory compliance and optimizing the material's chemical stability in food packaging and medical applications.

Additive Leaching: Mechanisms and Influencing Factors

Additive leaching in polyethylene involves the diffusion of low molecular weight additives, such as antioxidants, plasticizers, and slip agents, from the polymer matrix into surrounding environments. This process is influenced by factors including polymer crystallinity, temperature, additive polarity, and environmental conditions like solvent type and exposure duration. Understanding these mechanisms is essential for controlling additive release to ensure product safety and performance in applications such as food packaging and medical devices.

Key Differences Between Monomer Migration and Additive Leaching

Monomer migration involves the movement of unreacted ethylene molecules from polyethylene into surrounding materials, whereas additive leaching refers to the release of intentionally added substances like antioxidants or plasticizers. Monomer migration typically affects material purity and safety, while additive leaching impacts the functional properties and toxicity of the polyethylene product. Understanding the differing chemical structures and solubility profiles between migrating monomers and leached additives is critical for optimizing polyethylene performance and compliance with food contact regulations.

Factors Affecting Monomer Migration in Polyethylene

Monomer migration in polyethylene is influenced by polymer structure, temperature, and diffusion coefficients. High temperatures increase molecular mobility, accelerating monomer migration rates. Additionally, polymer crystallinity and molecular weight distribution impact the extent and speed of monomer diffusion through the polyethylene matrix.

Additives Commonly Used in Polyethylene Manufacturing

Additives commonly used in polyethylene manufacturing include antioxidants, UV stabilizers, plasticizers, and slip agents, which can migrate from the polymer matrix through additive leaching rather than monomer migration. While monomer migration involves residual ethylene monomers diffusing out, additive leaching refers to the diffusion and release of these incorporated substances that improve polyethylene's mechanical and chemical properties. Understanding the leaching behavior of additives is essential for assessing polyethylene's safety and performance in food packaging and medical applications.

Health and Environmental Impacts of Monomer Migration

Monomer migration from polyethylene poses significant health risks due to potential exposure to residual ethylene monomers, which can contribute to toxicological effects such as respiratory irritation and long-term carcinogenicity. Unlike additive leaching, monomer migration involves the release of unreacted ethylene units that may directly interact with biological systems, leading to bioaccumulation and environmental persistence. Understanding the migration kinetics and controlling residual monomer content in polyethylene products are critical to minimizing adverse health outcomes and reducing environmental contamination.

Risks Associated with Additive Leaching from Polyethylene

Additive leaching from polyethylene poses significant risks due to the potential release of harmful substances such as plasticizers, stabilizers, and antioxidants into food or the environment. These leached chemicals can lead to toxicological effects, including endocrine disruption and carcinogenicity, as they accumulate in biological systems. Monitoring and controlling additive migration is crucial to ensure safety in food packaging and consumer products made from polyethylene.

Testing and Measuring Migration and Leaching in Polyethylene

Testing and measuring monomer migration and additive leaching in polyethylene involve advanced analytical techniques such as gas chromatography-mass spectrometry (GC-MS) and high-performance liquid chromatography (HPLC) to quantify trace levels of transferred substances. Migration tests often utilize food simulants or solvents under controlled conditions to mimic real-world exposure, while leaching studies focus on the release of additives over time, employing accelerated aging or extraction methods. Standardized protocols like ASTM and ISO ensure consistent assessment of polymer safety and compliance with regulatory limits for food contact materials.

Regulatory Guidelines for Polyethylene Safety and Compliance

Regulatory guidelines for polyethylene safety prioritize limiting monomer migration and additive leaching to ensure consumer health. Agencies such as the FDA and EFSA establish specific migration limits for residual ethylene monomers and additives like antioxidants or plasticizers, enforcing rigorous testing protocols. Compliance with these standards involves standardized migration testing under simulated use conditions to verify polyethylene products meet safety thresholds and prevent toxic exposure.

Monomer migration vs Additive leaching Infographic

materialdif.com

materialdif.com