PE copolymer offers enhanced flexibility and impact resistance compared to PE homopolymer, making it ideal for applications requiring durability under stress. PE homopolymer provides higher crystallinity and tensile strength, delivering better rigidity and chemical resistance suitable for rigid packaging and containers. Selecting between PE copolymer and homopolymer depends on the specific performance requirements of the end product.

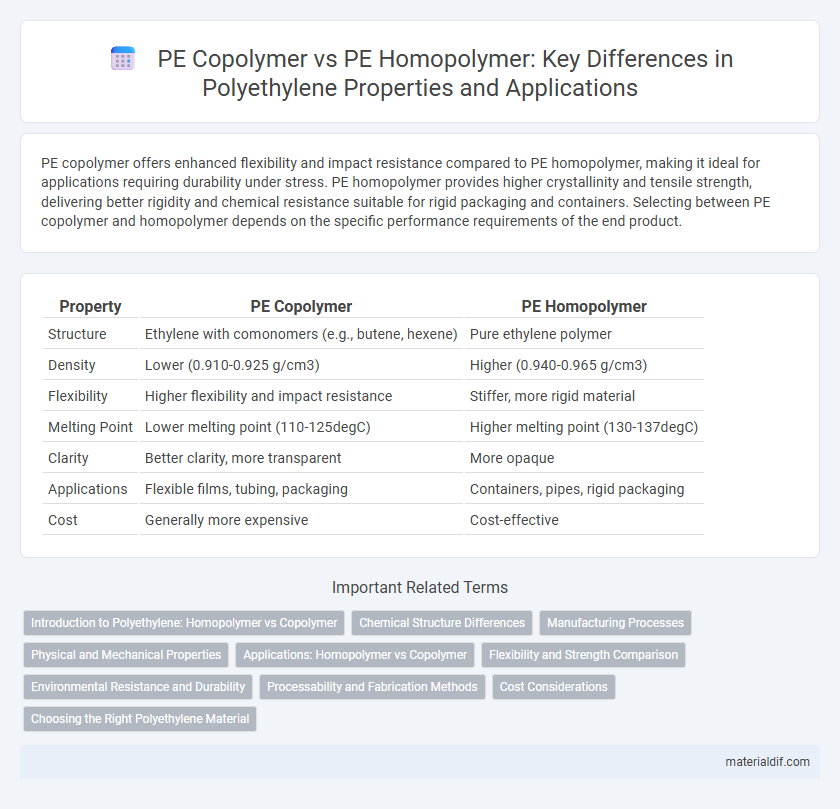

Table of Comparison

| Property | PE Copolymer | PE Homopolymer |

|---|---|---|

| Structure | Ethylene with comonomers (e.g., butene, hexene) | Pure ethylene polymer |

| Density | Lower (0.910-0.925 g/cm3) | Higher (0.940-0.965 g/cm3) |

| Flexibility | Higher flexibility and impact resistance | Stiffer, more rigid material |

| Melting Point | Lower melting point (110-125degC) | Higher melting point (130-137degC) |

| Clarity | Better clarity, more transparent | More opaque |

| Applications | Flexible films, tubing, packaging | Containers, pipes, rigid packaging |

| Cost | Generally more expensive | Cost-effective |

Introduction to Polyethylene: Homopolymer vs Copolymer

Polyethylene homopolymers consist of long chains of ethylene molecules, offering high density and crystallinity, which contribute to their enhanced mechanical strength and chemical resistance. In contrast, polyethylene copolymers incorporate comonomers such as hexene or butene into the polymer chain, resulting in improved flexibility, impact resistance, and lower melting points due to disrupted crystallinity. These structural differences enable homopolymers to excel in rigid packaging applications, while copolymers are preferred for products requiring toughness and elasticity like films and flexible containers.

Chemical Structure Differences

Polyethylene copolymers consist of ethylene monomers combined with other alpha-olefins, introducing irregularities in the polymer chain that enhance flexibility and impact resistance. In contrast, polyethylene homopolymers are composed solely of ethylene monomers, resulting in a highly crystalline and rigid molecular structure. These chemical structure differences significantly influence the physical properties and applications of each polyethylene type.

Manufacturing Processes

PE copolymer manufacturing involves incorporating comonomers such as butene, hexene, or octene during polymerization, using processes like gas phase or solution polymerization to enhance flexibility and impact resistance. In contrast, PE homopolymer production relies solely on ethylene monomer polymerized through Ziegler-Natta or metallocene catalysts, resulting in a more crystalline and rigid structure. Catalyst choice and polymerization conditions critically influence the molecular weight distribution and branching, affecting final material properties for applications ranging from packaging to automotive components.

Physical and Mechanical Properties

PE copolymer exhibits enhanced impact resistance and flexibility compared to PE homopolymer due to the incorporation of comonomers that disrupt crystallinity. PE homopolymer, characterized by higher density and crystallinity, offers superior tensile strength and stiffness but reduced elongation at break. The choice between PE copolymer and homopolymer influences applications requiring varying balances of toughness and rigidity.

Applications: Homopolymer vs Copolymer

PE homopolymer exhibits high tensile strength and rigidity, making it ideal for applications such as plastic bottles, containers, and pipes where durability and stiffness are crucial. PE copolymer, with its enhanced flexibility and impact resistance, is preferred in products like flexible packaging films, toys, and squeeze bottles that require elasticity and toughness. The choice between PE homopolymer and copolymer depends on the mechanical property requirements and specific end-use performance in industries like packaging, automotive, and consumer goods.

Flexibility and Strength Comparison

Polyethylene (PE) copolymers exhibit enhanced flexibility compared to PE homopolymers due to the incorporation of comonomers that disrupt the crystalline structure, allowing greater chain mobility. PE homopolymers typically provide higher tensile strength and stiffness owing to their more uniform and tightly packed molecular chains. The balance between flexibility and strength in PE materials depends on the copolymer composition and processing conditions, with copolymers favored for applications requiring flexibility and homopolymers suited for high-strength uses.

Environmental Resistance and Durability

Polyethylene copolymers exhibit enhanced environmental resistance compared to homopolymers due to their improved flexibility and impact strength, which increase durability under varying weather conditions. PE copolymers' branched molecular structure provides superior resistance to stress cracking and UV radiation, extending the lifespan of outdoor applications. Homopolymers, while having higher tensile strength, are more prone to brittleness and degradation when exposed to harsh environmental factors over time.

Processability and Fabrication Methods

PE copolymer exhibits enhanced processability compared to PE homopolymer due to its improved flexibility and lower melting point, which allows for easier molding and extrusion. Copolymers adapt well to various fabrication methods such as blow molding, injection molding, and film extrusion, enabling diverse applications from packaging to automotive parts. Homopolymers, with higher crystallinity and melting temperatures, require more precise temperature control during processing to maintain dimensional stability and mechanical strength.

Cost Considerations

PE copolymers generally have higher production costs than PE homopolymers due to the incorporation of additional monomers and more complex polymerization processes. The enhanced properties of copolymers, such as improved flexibility and impact resistance, justify the increased price in applications requiring these attributes. Homopolymers remain cost-effective for uses demanding rigidity and chemical resistance, offering economic advantages in bulk manufacturing.

Choosing the Right Polyethylene Material

PE copolymers offer enhanced toughness and flexibility compared to PE homopolymers, making them ideal for applications requiring impact resistance and clarity. Homopolymers provide higher density and stiffness, suitable for rigid packaging and containers with superior chemical resistance. Selecting the appropriate polyethylene material depends on balancing mechanical properties, environmental stress resistance, and end-use performance requirements.

PE copolymer vs PE homopolymer Infographic

materialdif.com

materialdif.com