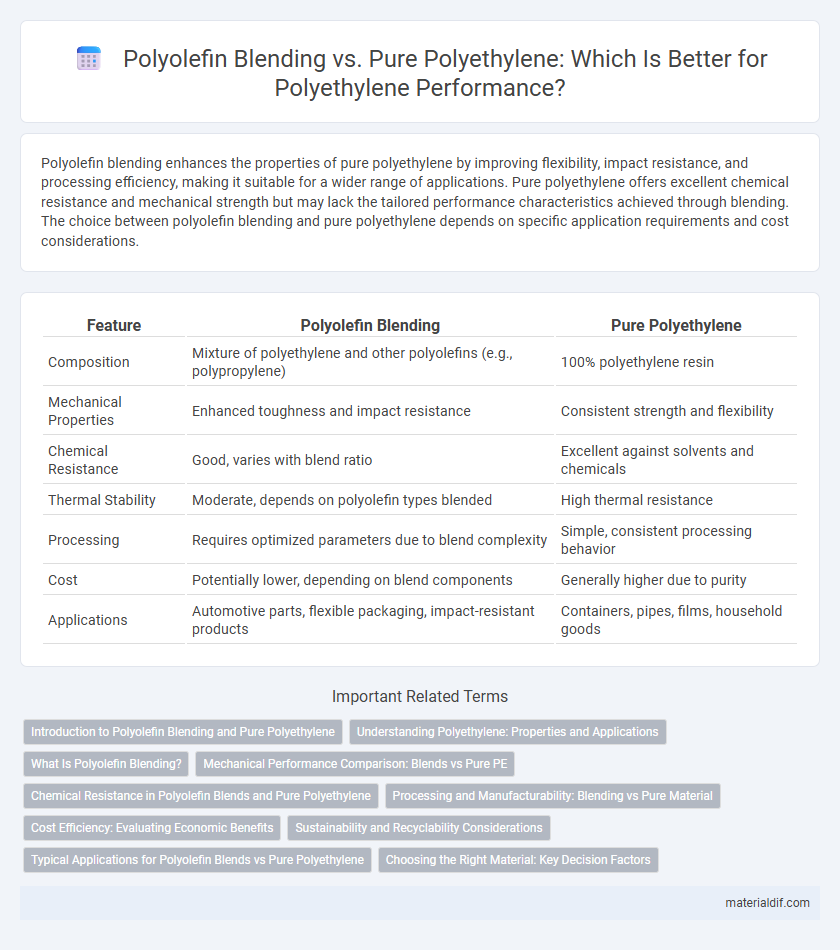

Polyolefin blending enhances the properties of pure polyethylene by improving flexibility, impact resistance, and processing efficiency, making it suitable for a wider range of applications. Pure polyethylene offers excellent chemical resistance and mechanical strength but may lack the tailored performance characteristics achieved through blending. The choice between polyolefin blending and pure polyethylene depends on specific application requirements and cost considerations.

Table of Comparison

| Feature | Polyolefin Blending | Pure Polyethylene |

|---|---|---|

| Composition | Mixture of polyethylene and other polyolefins (e.g., polypropylene) | 100% polyethylene resin |

| Mechanical Properties | Enhanced toughness and impact resistance | Consistent strength and flexibility |

| Chemical Resistance | Good, varies with blend ratio | Excellent against solvents and chemicals |

| Thermal Stability | Moderate, depends on polyolefin types blended | High thermal resistance |

| Processing | Requires optimized parameters due to blend complexity | Simple, consistent processing behavior |

| Cost | Potentially lower, depending on blend components | Generally higher due to purity |

| Applications | Automotive parts, flexible packaging, impact-resistant products | Containers, pipes, films, household goods |

Introduction to Polyolefin Blending and Pure Polyethylene

Polyolefin blending involves combining polyethylene with other polyolefins such as polypropylene to enhance specific material properties like impact resistance, flexibility, and chemical stability. Pure polyethylene, typically categorized into high-density (HDPE) and low-density (LDPE) variants, offers inherent benefits including excellent moisture resistance, chemical inertness, and ease of processing. Understanding the differences between pure polyethylene and polyolefin blends is crucial for selecting the right polymer formulation for applications requiring tailored mechanical and thermal performance.

Understanding Polyethylene: Properties and Applications

Polyolefin blending enhances polyethylene by combining its inherent properties like flexibility, chemical resistance, and durability with other polyolefins to achieve tailored mechanical strength and improved thermal stability. Pure polyethylene offers high impact resistance and excellent moisture barrier, making it ideal for packaging, containers, and pipes, while blends extend its usability in automotive parts and industrial applications. The choice between pure polyethylene and polyolefin blends depends on the specific performance requirements such as tensile strength, chemical compatibility, and environmental stress cracking resistance.

What Is Polyolefin Blending?

Polyolefin blending involves combining polyethylene with other polyolefins like polypropylene to enhance material properties such as flexibility, impact resistance, and chemical stability. This process optimizes performance by leveraging the complementary characteristics of different polyolefins, resulting in tailored mechanical and thermal properties not achievable with pure polyethylene. Polyolefin blends find widespread applications in packaging, automotive parts, and consumer goods due to their improved durability and processing versatility compared to pure polyethylene.

Mechanical Performance Comparison: Blends vs Pure PE

Polyolefin blending enhances mechanical properties compared to pure polyethylene by improving impact resistance, tensile strength, and flexibility due to synergistic effects between different polymer chains. Blended materials often exhibit superior durability and stress crack resistance, making them suitable for demanding applications where pure PE may fall short. The tailored composition of polyolefin blends allows optimization of mechanical performance, balancing rigidity and toughness more effectively than pure polyethylene alone.

Chemical Resistance in Polyolefin Blends and Pure Polyethylene

Polyethylene exhibits exceptional chemical resistance, making it highly effective against acids, bases, and solvents, which is a key advantage over many polyolefin blends. Polyolefin blends, such as mixtures of polyethylene with polypropylene or ethylene-propylene copolymers, may experience compromised chemical resistance due to differences in polymer compatibility and polarity. The molecular structure and crystallinity of pure polyethylene contribute to its superior barrier properties and stability in aggressive chemical environments compared to polyolefin blends.

Processing and Manufacturability: Blending vs Pure Material

Polyolefin blending enhances processability by improving melt flow characteristics compared to pure polyethylene, facilitating easier extrusion and molding operations. Blends often exhibit reduced viscosity and better thermal stability, which leads to shorter cycle times and lower energy consumption during manufacturing. Pure polyethylene offers consistent material properties but may require more precise processing conditions to avoid defects such as warping or incomplete filling.

Cost Efficiency: Evaluating Economic Benefits

Polyolefin blending offers significant cost efficiency compared to pure polyethylene by utilizing a combination of polymers such as polypropylene, which can reduce raw material expenses and enhance processing flexibility. This blending approach lowers production costs while maintaining key performance characteristics like tensile strength and chemical resistance, making it economically advantageous for manufacturers. Pure polyethylene, though consistent in quality, generally incurs higher material costs due to its singular polymer composition and less optimized resource utilization.

Sustainability and Recyclability Considerations

Polyolefin blending enhances sustainability by improving material properties and enabling easier recycling compared to pure polyethylene, which often faces limitations due to its homogeneous polymer structure. Blends with polypropylene or other polyolefins can optimize mechanical performance and facilitate circular economy processes by enabling more efficient sorting and reprocessing in recycling streams. However, pure polyethylene remains preferable for specific applications requiring high purity in recycled outputs, highlighting a trade-off between blend versatility and recyclate quality.

Typical Applications for Polyolefin Blends vs Pure Polyethylene

Polyolefin blends combine polyethylene with polypropylene or other polyolefins, enhancing mechanical properties and chemical resistance, making them suitable for automotive parts, packaging films, and consumer goods. Pure polyethylene maintains excellent flexibility and moisture barrier properties, ideal for applications like plastic bags, containers, and pipes. The selection between polyolefin blends and pure polyethylene depends on the required durability, rigidity, and environmental resistance for specific industrial or consumer use cases.

Choosing the Right Material: Key Decision Factors

Polyolefin blending offers enhanced mechanical properties, improved chemical resistance, and cost efficiency compared to pure polyethylene, making it ideal for applications requiring tailored performance. Pure polyethylene provides consistent purity, excellent processability, and superior recyclability, which is critical for medical and food packaging industries. Key decision factors include required strength, flexibility, environmental impact, and budget constraints to ensure optimal material selection for specific industrial or commercial applications.

Polyolefin Blending vs Pure Polyethylene Infographic

materialdif.com

materialdif.com