High Molecular Weight Polyethylene (HMWPE) offers enhanced strength and chemical resistance compared to standard polyethylene, making it suitable for durable packaging and industrial applications. Ultra-High Molecular Weight Polyethylene (UHMWPE) exhibits even greater impact resistance, low friction, and wear properties, ideal for heavy-duty uses such as medical devices and ballistic protection. The difference lies primarily in molecular weight, where UHMWPE's longer chains result in superior toughness and longevity.

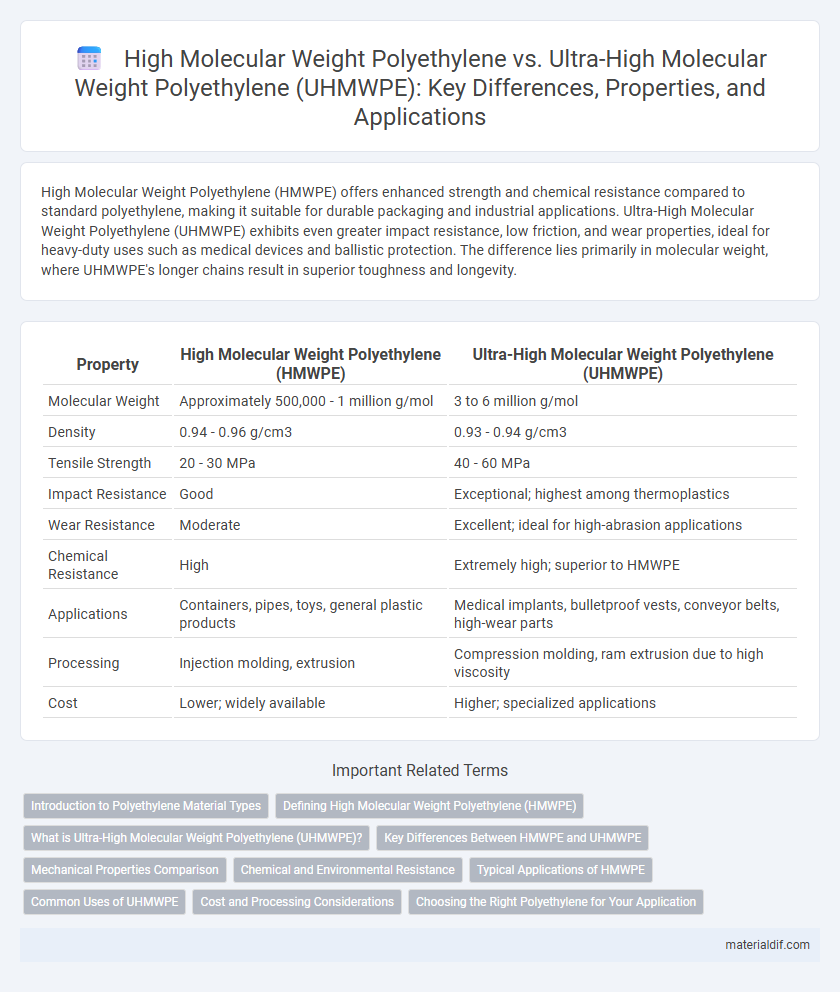

Table of Comparison

| Property | High Molecular Weight Polyethylene (HMWPE) | Ultra-High Molecular Weight Polyethylene (UHMWPE) |

|---|---|---|

| Molecular Weight | Approximately 500,000 - 1 million g/mol | 3 to 6 million g/mol |

| Density | 0.94 - 0.96 g/cm3 | 0.93 - 0.94 g/cm3 |

| Tensile Strength | 20 - 30 MPa | 40 - 60 MPa |

| Impact Resistance | Good | Exceptional; highest among thermoplastics |

| Wear Resistance | Moderate | Excellent; ideal for high-abrasion applications |

| Chemical Resistance | High | Extremely high; superior to HMWPE |

| Applications | Containers, pipes, toys, general plastic products | Medical implants, bulletproof vests, conveyor belts, high-wear parts |

| Processing | Injection molding, extrusion | Compression molding, ram extrusion due to high viscosity |

| Cost | Lower; widely available | Higher; specialized applications |

Introduction to Polyethylene Material Types

High Molecular Weight Polyethylene (HMWPE) offers enhanced tensile strength and durability compared to standard polyethylene, making it suitable for industrial applications requiring toughness. Ultra-High Molecular Weight Polyethylene (UHMWPE) contains even longer polymer chains, providing superior abrasion resistance, impact strength, and low friction properties ideal for medical devices and protective gear. Both materials exhibit excellent chemical resistance and low moisture absorption, but UHMWPE stands out for extreme wear environments and high-performance demanding applications.

Defining High Molecular Weight Polyethylene (HMWPE)

High Molecular Weight Polyethylene (HMWPE) is characterized by a molecular weight typically ranging from 100,000 to 500,000 g/mol, offering enhanced strength and chemical resistance compared to low molecular weight variants. It features a more branched polymer chain structure than Ultra-High Molecular Weight Polyethylene (UHMWPE), which possesses molecular weights exceeding 1 million g/mol, resulting in distinct mechanical and wear properties. HMWPE is widely used in applications requiring a balance of durability and processability, such as piping, geomembranes, and automotive components.

What is Ultra-High Molecular Weight Polyethylene (UHMWPE)?

Ultra-High Molecular Weight Polyethylene (UHMWPE) is a subset of polyethylene characterized by extremely long polymer chains with molecular weights typically between 3.5 to 7.5 million atomic mass units, significantly higher than High Molecular Weight Polyethylene (HMWPE). This molecular structure grants UHMWPE exceptional properties such as outstanding abrasion resistance, high impact strength, and low coefficient of friction. UHMWPE is widely used in applications requiring superior durability and wear resistance, including medical devices, ballistic protection, and industrial components.

Key Differences Between HMWPE and UHMWPE

High Molecular Weight Polyethylene (HMWPE) typically has a molecular weight ranging from 100,000 to 250,000 g/mol, offering higher tensile strength and better chemical resistance compared to standard polyethylene. Ultra-High Molecular Weight Polyethylene (UHMWPE) possesses an exceptionally high molecular weight, often exceeding 3,000,000 g/mol, resulting in superior abrasion resistance, impact strength, and low friction properties. The increased molecular weight in UHMWPE provides enhanced durability for demanding applications such as medical implants, ballistic armor, and high-wear industrial components, distinguishing it from HMWPE in performance and cost.

Mechanical Properties Comparison

High Molecular Weight Polyethylene (HMWPE) offers excellent tensile strength and impact resistance, making it suitable for a wide range of industrial applications, but Ultra-High Molecular Weight Polyethylene (UHMWPE) surpasses it with significantly higher tensile strength and superior abrasion resistance. UHMWPE demonstrates enhanced wear resistance and a much lower coefficient of friction, which improves its performance in demanding environments such as medical implants, bulletproof vests, and heavy-duty conveyor systems. The molecular weight of UHMWPE, typically ranging from 3.5 to 7.5 million g/mol, provides exceptional toughness and durability compared to HMWPE's lower range of 0.3 to 0.5 million g/mol, resulting in notable mechanical property improvements.

Chemical and Environmental Resistance

High Molecular Weight Polyethylene (HMWPE) exhibits strong chemical resistance to acids, bases, and alcohols, making it suitable for a variety of chemical handling applications. Ultra-High Molecular Weight Polyethylene (UHMWPE) offers superior abrasion resistance and exceptional resistance to organic solvents and corrosive chemicals, enhancing its durability in harsh environments. Both HMWPE and UHMWPE demonstrate excellent environmental resistance, including resistance to UV radiation and moisture, but UHMWPE's higher molecular weight imparts greater toughness and longer service life in extreme conditions.

Typical Applications of HMWPE

High Molecular Weight Polyethylene (HMWPE) is widely used in applications requiring a balance of strength and processability, such as manufacturing plastic containers, pipes, and automotive fuel tanks. Its moderate molecular weight enables easier molding and extrusion compared to Ultra-High Molecular Weight Polyethylene (UHMWPE), making it suitable for consumer goods and packaging materials. HMWPE also finds use in industrial components like conveyor belts and liners where abrasion resistance is important but extreme wear resistance of UHMWPE is not necessary.

Common Uses of UHMWPE

Ultra-High Molecular Weight Polyethylene (UHMWPE) exhibits exceptional abrasion resistance and high impact strength, making it ideal for applications such as medical implants, ballistic protection, and conveyor system components. Its low coefficient of friction and chemical inertness extend its use to industrial liners, gears, and marine equipment. These properties distinguish UHMWPE from High Molecular Weight Polyethylene, which is typically used in less demanding packaging and consumer goods.

Cost and Processing Considerations

High Molecular Weight Polyethylene (HMWPE) typically offers lower raw material costs compared to Ultra-High Molecular Weight Polyethylene (UHMWPE), making it more economical for large-scale manufacturing. UHMWPE requires specialized processing techniques such as compression molding or ram extrusion due to its extremely high molecular weight, which increases production complexity and energy consumption. Cost factors for UHMWPE also include longer cycle times and higher equipment wear, impacting overall manufacturing expenses relative to HMWPE.

Choosing the Right Polyethylene for Your Application

High Molecular Weight Polyethylene (HMWPE) offers superior tensile strength and durability compared to standard polyethylene, making it ideal for applications like piping and geomembranes. Ultra-High Molecular Weight Polyethylene (UHMWPE) provides even greater abrasion resistance and impact strength, commonly used in medical devices, bulletproof vests, and industrial liners. Selecting between HMWPE and UHMWPE depends on factors such as load-bearing requirements, wear resistance, and environmental exposure to ensure optimal performance and longevity.

High Molecular Weight Polyethylene vs Ultra-High Molecular Weight Polyethylene (UHMWPE) Infographic

materialdif.com

materialdif.com