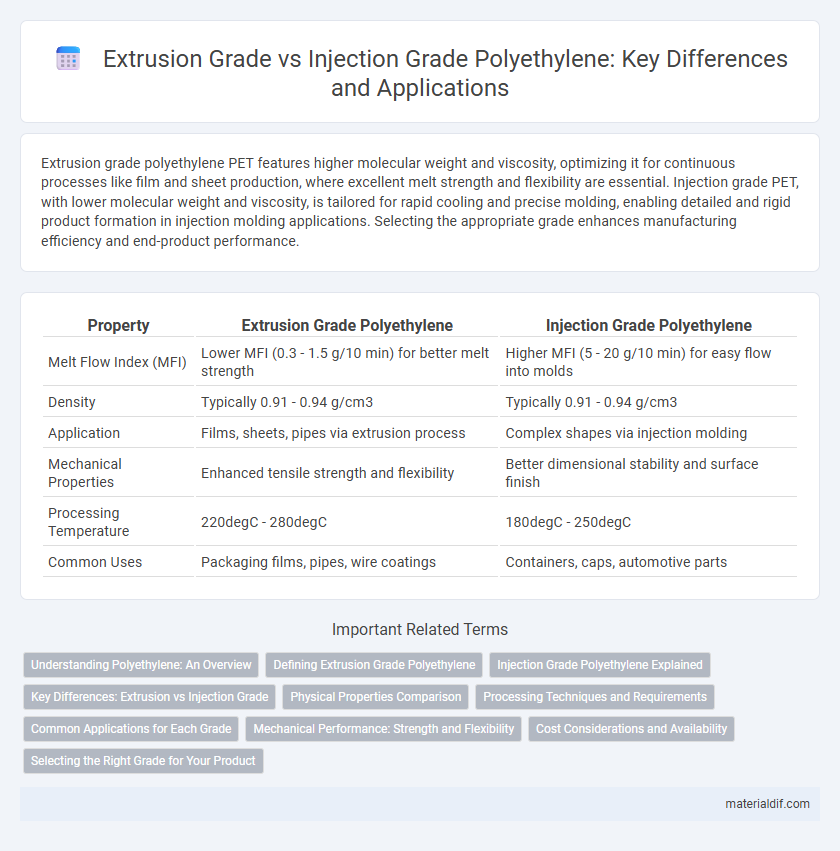

Extrusion grade polyethylene PET features higher molecular weight and viscosity, optimizing it for continuous processes like film and sheet production, where excellent melt strength and flexibility are essential. Injection grade PET, with lower molecular weight and viscosity, is tailored for rapid cooling and precise molding, enabling detailed and rigid product formation in injection molding applications. Selecting the appropriate grade enhances manufacturing efficiency and end-product performance.

Table of Comparison

| Property | Extrusion Grade Polyethylene | Injection Grade Polyethylene |

|---|---|---|

| Melt Flow Index (MFI) | Lower MFI (0.3 - 1.5 g/10 min) for better melt strength | Higher MFI (5 - 20 g/10 min) for easy flow into molds |

| Density | Typically 0.91 - 0.94 g/cm3 | Typically 0.91 - 0.94 g/cm3 |

| Application | Films, sheets, pipes via extrusion process | Complex shapes via injection molding |

| Mechanical Properties | Enhanced tensile strength and flexibility | Better dimensional stability and surface finish |

| Processing Temperature | 220degC - 280degC | 180degC - 250degC |

| Common Uses | Packaging films, pipes, wire coatings | Containers, caps, automotive parts |

Understanding Polyethylene: An Overview

Extrusion grade polyethylene is formulated for continuous shaping processes, offering enhanced melt flow and flexibility ideal for films, pipes, and sheets. Injection grade polyethylene features higher molecular weight and viscosity, providing superior strength and dimensional stability for molded items like containers and caps. Understanding these distinctions helps optimize material selection for specific manufacturing applications and product performance.

Defining Extrusion Grade Polyethylene

Extrusion grade polyethylene is specifically designed for manufacturing processes that involve continuous shaping, such as film blowing, sheet extrusion, and pipe production, due to its optimal melt flow index and low melt viscosity. This grade typically features a higher molecular weight distribution that ensures excellent melt strength and uniform parison formation, which are critical for extrusion stability and product consistency. Its tailored thermal and rheological properties distinguish it from injection grade polyethylene, which is optimized for mold filling and detailed part formation.

Injection Grade Polyethylene Explained

Injection grade polyethylene features a lower melt flow index compared to extrusion grade, enabling precise molding and detailed shapes in injection molding processes. Its distinct molecular weight distribution offers enhanced mechanical properties and surface finish, making it ideal for products requiring tight tolerances and complex geometries. Manufacturers select injection grade polyethylene for automotive parts, containers, and intricate consumer goods due to its consistent flow and durability under high pressure.

Key Differences: Extrusion vs Injection Grade

Extrusion grade polyethylene features higher melt flow index (MFI) values, promoting smoother flow during continuous processes like film and pipe production, whereas injection grade polyethylene exhibits lower MFI for better dimensional stability and mechanical strength in molded parts. Extrusion grade typically contains fewer additives to enhance flexibility and impact resistance, while injection grade formulations prioritize rigidity and surface finish quality. Processing temperature ranges differ, with extrusion requiring consistent heat for long-duration flow and injection molding needing rapid melting and solidification cycles.

Physical Properties Comparison

Extrusion grade polyethylene typically exhibits higher melt flow index (MFI) values, allowing better flow during the extrusion process, whereas injection grade polyethylene has lower MFI for enhanced structural integrity in molded parts. Extrusion grade usually features moderate density and tensile strength to balance flexibility and durability, while injection grade prioritizes higher tensile strength and impact resistance for precise and robust injection-molded components. Both grades demonstrate varying crystallinity levels, directly influencing their stiffness and thermal stability suited for their specific manufacturing processes.

Processing Techniques and Requirements

Extrusion grade polyethylene is designed with lower melt flow index (MFI), allowing it to withstand continuous heat and pressure during the extrusion process for applications like films and sheets. Injection grade polyethylene, with higher MFI, melts quickly to fill molds rapidly, making it ideal for complex shapes and detailed components. Processing techniques for extrusion demand steady melt flow and thermal stability, while injection molding requires fast melting and precise viscosity control to ensure accurate part formation.

Common Applications for Each Grade

Extrusion grade polyethylene is commonly used for producing films, sheets, pipes, and coatings due to its excellent flow properties and consistency. Injection grade polyethylene is widely utilized in manufacturing molded products such as containers, caps, automotive parts, and toys because of its superior melt strength and dimensional stability. Both grades are essential in packaging, automotive, and construction industries, tailored to process-specific requirements.

Mechanical Performance: Strength and Flexibility

Extrusion grade polyethylene typically exhibits higher flexibility and excellent elongation properties, making it suitable for continuous shaping processes like tubing and films. Injection grade polyethylene, characterized by greater tensile strength and rigidity, is optimized for molding complex, load-bearing components with precise dimensional stability. The mechanical performance difference stems from molecular weight distribution and branching, influencing the balance between strength and flexibility in each grade.

Cost Considerations and Availability

Extrusion grade polyethylene typically offers lower material costs due to its simpler polymer structure and higher availability, making it ideal for large-scale, continuous processing applications. Injection grade polyethylene, with its specialized resin properties for mold flow and precision, tends to be more expensive and less readily available, impacting budget considerations for complex part manufacturing. Evaluating the balance between cost efficiency and material performance is crucial when selecting between extrusion and injection grades for specific production needs.

Selecting the Right Grade for Your Product

Extrusion grade polyethylene is optimized for continuous shaping processes, offering superior melt strength and flow properties ideal for films, sheets, and pipes. Injection grade polyethylene features balanced melt flow rates and impact resistance, making it suitable for precise molding of complex parts and containers. Selecting the right grade depends on the product's design complexity, mechanical requirements, and end-use application, ensuring optimal performance and cost-efficiency.

Extrusion Grade vs Injection Grade Infographic

materialdif.com

materialdif.com