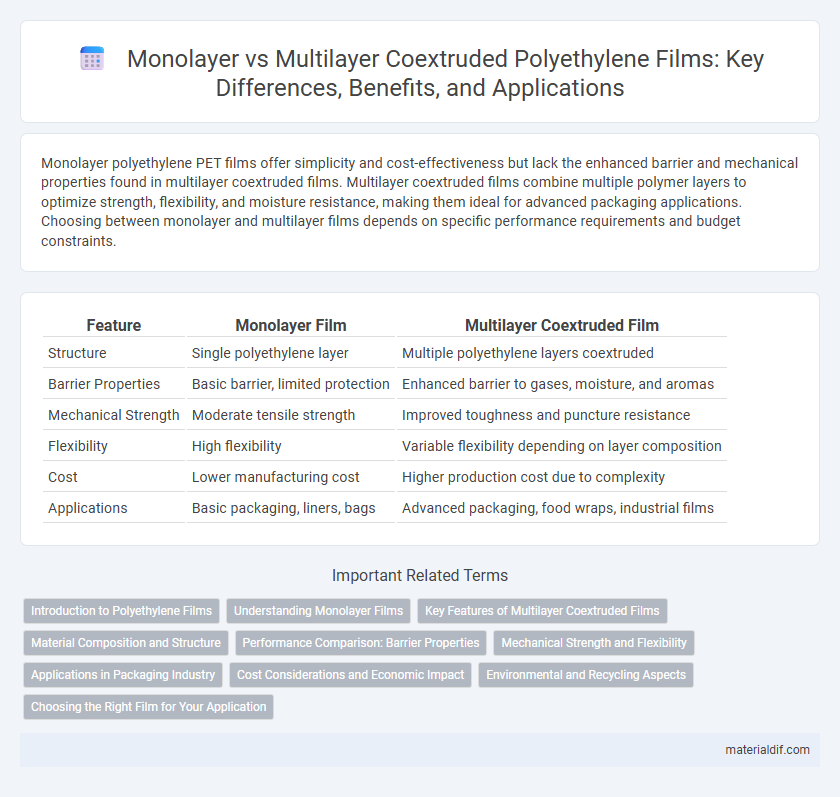

Monolayer polyethylene PET films offer simplicity and cost-effectiveness but lack the enhanced barrier and mechanical properties found in multilayer coextruded films. Multilayer coextruded films combine multiple polymer layers to optimize strength, flexibility, and moisture resistance, making them ideal for advanced packaging applications. Choosing between monolayer and multilayer films depends on specific performance requirements and budget constraints.

Table of Comparison

| Feature | Monolayer Film | Multilayer Coextruded Film |

|---|---|---|

| Structure | Single polyethylene layer | Multiple polyethylene layers coextruded |

| Barrier Properties | Basic barrier, limited protection | Enhanced barrier to gases, moisture, and aromas |

| Mechanical Strength | Moderate tensile strength | Improved toughness and puncture resistance |

| Flexibility | High flexibility | Variable flexibility depending on layer composition |

| Cost | Lower manufacturing cost | Higher production cost due to complexity |

| Applications | Basic packaging, liners, bags | Advanced packaging, food wraps, industrial films |

Introduction to Polyethylene Films

Polyethylene films are widely used in packaging due to their excellent moisture barrier, flexibility, and durability. Monolayer polyethylene films consist of a single uniform layer, offering simplicity and cost-effectiveness but limited performance in barrier properties. Multilayer coextruded films combine several polyethylene layers with different polymers, enhancing mechanical strength, oxygen and moisture resistance, and overall functionality for diverse industrial applications.

Understanding Monolayer Films

Monolayer polyethylene films consist of a single layer of polymer, providing uniform thickness and consistent mechanical properties ideal for applications such as packaging and liners. These films offer cost-effective production and simplified recycling compared to multilayer coextruded films, which integrate multiple polymer layers to enhance barrier properties and strength. Understanding the physical and chemical characteristics of monolayer films aids in selecting the appropriate film type for specific industrial uses where uniformity and clarity are critical.

Key Features of Multilayer Coextruded Films

Multilayer coextruded polyethylene films offer enhanced barrier properties, combining layers with different polymers to optimize moisture, oxygen, and chemical resistance beyond the capabilities of monolayer films. These films exhibit superior mechanical strength and flexibility, enabling improved puncture resistance and durability in packaging applications. Advanced multilayer structures enable tailored functional attributes such as heat sealability, printability, and transparency, making them ideal for high-performance packaging solutions.

Material Composition and Structure

Monolayer films consist of a single layer of polyethylene, offering uniform material properties and easier recyclability due to their simple composition. Multilayer coextruded films combine several layers of different polyethylene grades or other polymers, optimizing barrier performance, mechanical strength, and flexibility through tailored material structures. The multilayer structure enhances functionality for specialized applications but may complicate recycling processes compared to monolayer films.

Performance Comparison: Barrier Properties

Monolayer polyethylene films typically exhibit lower barrier properties against oxygen and moisture compared to multilayer coextruded films, which incorporate specialized barrier resins to enhance performance. Multilayer coextruded films achieve superior gas and vapor resistance by combining multiple layers with distinct functions, improving shelf life and product protection. Advanced coextrusion techniques allow precise control over layer thickness and composition, optimizing barrier efficiency while maintaining mechanical strength and flexibility.

Mechanical Strength and Flexibility

Monolayer polyethylene films typically offer good flexibility but are limited in mechanical strength compared to multilayer coextruded films, which combine different polymer layers to enhance tensile strength, puncture resistance, and durability. The multilayer structure enables tailored properties by integrating high-strength materials with flexible layers, resulting in films optimized for demanding packaging and industrial applications. Mechanical performance improvements in multilayer coextruded films directly contribute to longer shelf life and better protection without sacrificing flexibility.

Applications in Packaging Industry

Monolayer polyethylene films are widely used in packaging for their cost-effectiveness and simplicity, ideal for products requiring basic moisture barrier and flexibility, such as grocery bags and shrink wraps. Multilayer coextruded films combine various polymers to enhance barrier properties, mechanical strength, and sealability, making them suitable for packaging perishable food items, pharmaceuticals, and industrial goods that demand extended shelf life and protection. The packaging industry benefits from multilayer films when specific performance attributes like oxygen and aroma barriers are critical, while monolayer films serve efficiently in less demanding applications.

Cost Considerations and Economic Impact

Monolayer polyethylene films generally offer lower production costs due to simpler manufacturing processes and reduced material usage, making them economically viable for applications with minimal barrier requirements. Multilayer coextruded films, while more expensive because of complex equipment and multiple resin layers, provide enhanced mechanical properties and superior barrier performance, potentially reducing product spoilage and extending shelf life, which can offset initial higher costs. Evaluating cost-effectiveness involves balancing immediate material expenses against long-term economic benefits related to product protection and market competitiveness.

Environmental and Recycling Aspects

Monolayer polyethylene films offer simplicity in recycling due to their uniform composition, facilitating efficient sorting and processing in existing recycling streams. Multilayer coextruded films, while enhancing mechanical and barrier properties, pose significant challenges for recycling because their composite layers are often incompatible and difficult to separate, leading to increased environmental impact. Advances in compatible polymers and chemical recycling technologies are critical to improving the sustainability of multilayer polyethylene packaging.

Choosing the Right Film for Your Application

Monolayer polyethylene film offers simplicity and cost-effectiveness, making it ideal for applications requiring basic barrier properties and ease of recycling. Multilayer coextruded polyethylene film provides enhanced performance with tailored barrier characteristics, mechanical strength, and versatility, suitable for demanding packaging needs like food preservation and chemical resistance. Selecting the right film depends on balancing application-specific factors such as barrier requirements, durability, budget constraints, and environmental impact.

Monolayer Film vs Multilayer Coextruded Film Infographic

materialdif.com

materialdif.com