Antistatic polyethylene reduces static electricity buildup by dissipating surface charges, making it ideal for packaging sensitive electronic components without risk of electrostatic discharge. Conductive polyethylene contains conductive fillers that create a continuous electrical path, allowing for rapid grounding and protection in environments with higher static discharge hazards. Both materials enhance safety in electronic applications, though conductive polyethylene offers stronger protection due to its superior electrical conductivity.

Table of Comparison

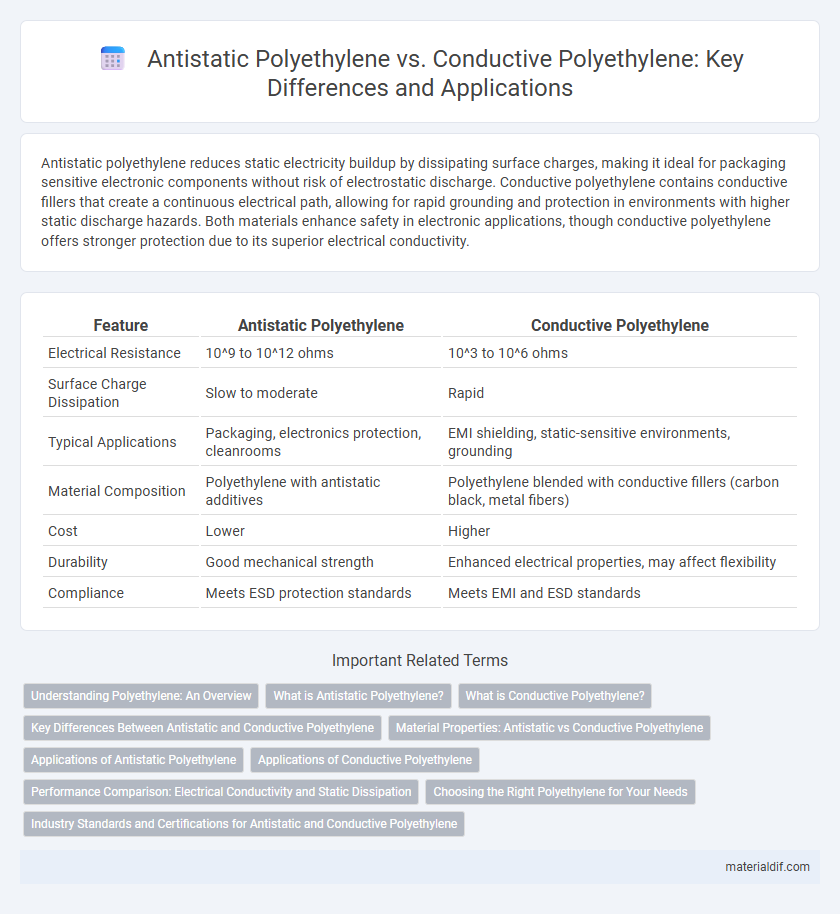

| Feature | Antistatic Polyethylene | Conductive Polyethylene |

|---|---|---|

| Electrical Resistance | 10^9 to 10^12 ohms | 10^3 to 10^6 ohms |

| Surface Charge Dissipation | Slow to moderate | Rapid |

| Typical Applications | Packaging, electronics protection, cleanrooms | EMI shielding, static-sensitive environments, grounding |

| Material Composition | Polyethylene with antistatic additives | Polyethylene blended with conductive fillers (carbon black, metal fibers) |

| Cost | Lower | Higher |

| Durability | Good mechanical strength | Enhanced electrical properties, may affect flexibility |

| Compliance | Meets ESD protection standards | Meets EMI and ESD standards |

Understanding Polyethylene: An Overview

Antistatic polyethylene contains additives that reduce surface resistivity to prevent static charge buildup, making it ideal for packaging sensitive electronic components. Conductive polyethylene is engineered with conductive fillers, such as carbon black or metallic fibers, which provide a continuous path for electrical conductivity to safely dissipate static electricity. Both types enhance polyethylene's functionality in electrostatic discharge-sensitive environments but serve distinct roles based on their differing electrical properties.

What is Antistatic Polyethylene?

Antistatic polyethylene is a type of polyethylene enhanced with additives that reduce surface electrical charges, preventing the buildup of static electricity. It maintains the material's inherent insulating properties while minimizing dust attraction and static discharge risks in packaging applications. Unlike conductive polyethylene, which allows electrical current to flow, antistatic polyethylene only dissipates static charges without becoming fully conductive.

What is Conductive Polyethylene?

Conductive polyethylene is a specially formulated polymer designed to allow the flow of electrical current by incorporating conductive fillers such as carbon black or metal particles. This type of polyethylene exhibits low electrical resistivity, making it ideal for applications requiring static dissipation or electromagnetic interference shielding. Unlike antistatic polyethylene, which only reduces surface static buildup, conductive polyethylene provides continuous conductivity throughout the material for enhanced electrical performance.

Key Differences Between Antistatic and Conductive Polyethylene

Antistatic polyethylene reduces surface static charge to prevent dust attraction and minimize electrostatic discharge, while conductive polyethylene facilitates electrical current flow to safely dissipate charge. Antistatic variants typically have higher volume resistivity (10^9 to 10^12 ohm-cm), whereas conductive polyethylene exhibits lower resistivity (below 10^5 ohm-cm). The key difference lies in their electrical properties and targeted applications, with antistatic polyethylene used for static control and conductive polyethylene for grounding and electromagnetic interference shielding.

Material Properties: Antistatic vs Conductive Polyethylene

Antistatic polyethylene exhibits surface resistivity typically ranging from 10^9 to 10^12 ohms, minimizing static charge buildup without significantly altering the polymer's intrinsic insulating nature. Conductive polyethylene contains conductive fillers such as carbon black or metal fibers, reducing resistivity to below 10^5 ohms and enabling efficient electron flow for grounding applications. The selection between antistatic and conductive grades depends on the required level of electrical conductivity and the specific use case in electrostatic discharge (ESD) control or electromagnetic interference (EMI) shielding.

Applications of Antistatic Polyethylene

Antistatic polyethylene is widely used in packaging for electronic components and sensitive devices to prevent static electricity buildup that can damage circuitry. Its applications extend to food packaging, where static control improves material handling and reduces dust attraction. Unlike conductive polyethylene, which is mainly used for electromagnetic shielding, antistatic polyethylene enhances safety and product integrity in environments vulnerable to electrostatic discharge.

Applications of Conductive Polyethylene

Conductive polyethylene is widely used in applications requiring the dissipation of static electricity to prevent ignition hazards, such as in fuel packaging, electronic component housings, and pharmaceutical packaging. Its ability to provide controlled electrical conductivity makes it ideal for grounding and shielding in electronic and industrial environments. Unlike antistatic polyethylene, which primarily reduces surface static charge, conductive polyethylene ensures continuous conductivity essential for safety-critical applications.

Performance Comparison: Electrical Conductivity and Static Dissipation

Antistatic polyethylene typically exhibits surface resistivity in the range of 10^9 to 10^11 ohms/sq, enabling efficient static charge dissipation without creating a conductive path, ideal for packaging sensitive electronics. Conductive polyethylene, enhanced with conductive fillers such as carbon black or metal fibers, demonstrates much lower resistivity values around 10^3 to 10^6 ohms/sq, ensuring superior electrical conductivity for applications requiring reliable grounding. Both materials effectively reduce electrostatic discharge risks, but conductive polyethylene offers enhanced performance in continuous static dissipation and electromagnetic interference shielding.

Choosing the Right Polyethylene for Your Needs

Antistatic polyethylene is designed to prevent static charge buildup by providing a low level of surface resistance, making it ideal for packaging sensitive electronic components. Conductive polyethylene offers significantly lower resistance, allowing it to safely dissipate static electricity in environments requiring robust electrostatic discharge (ESD) protection. Selecting the right polyethylene depends on the specific application's electrostatic control requirements, with antistatic suited for light protection and conductive favored for high-risk ESD environments.

Industry Standards and Certifications for Antistatic and Conductive Polyethylene

Antistatic polyethylene complies with industry standards such as ASTM D257 for surface resistivity and IEC 61340-5-1 for electrostatic control, ensuring effective dissipation of static charges in sensitive electronic environments. Conductive polyethylene meets stricter certifications including UL 746A for material characteristics and IEC 60093 for volume resistivity, enabling safe and reliable use in applications requiring electrical conductivity. Both materials undergo rigorous testing to conform with RoHS and REACH regulations, confirming their safety and environmental compliance for industrial use.

Antistatic polyethylene vs Conductive polyethylene Infographic

materialdif.com

materialdif.com