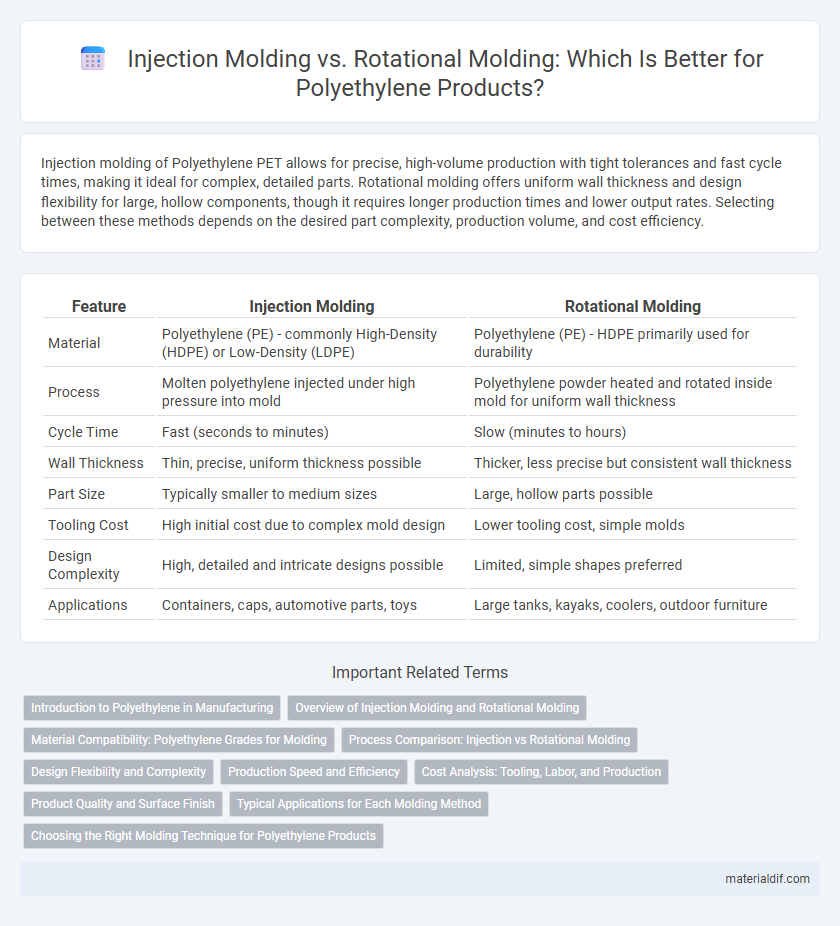

Injection molding of Polyethylene PET allows for precise, high-volume production with tight tolerances and fast cycle times, making it ideal for complex, detailed parts. Rotational molding offers uniform wall thickness and design flexibility for large, hollow components, though it requires longer production times and lower output rates. Selecting between these methods depends on the desired part complexity, production volume, and cost efficiency.

Table of Comparison

| Feature | Injection Molding | Rotational Molding |

|---|---|---|

| Material | Polyethylene (PE) - commonly High-Density (HDPE) or Low-Density (LDPE) | Polyethylene (PE) - HDPE primarily used for durability |

| Process | Molten polyethylene injected under high pressure into mold | Polyethylene powder heated and rotated inside mold for uniform wall thickness |

| Cycle Time | Fast (seconds to minutes) | Slow (minutes to hours) |

| Wall Thickness | Thin, precise, uniform thickness possible | Thicker, less precise but consistent wall thickness |

| Part Size | Typically smaller to medium sizes | Large, hollow parts possible |

| Tooling Cost | High initial cost due to complex mold design | Lower tooling cost, simple molds |

| Design Complexity | High, detailed and intricate designs possible | Limited, simple shapes preferred |

| Applications | Containers, caps, automotive parts, toys | Large tanks, kayaks, coolers, outdoor furniture |

Introduction to Polyethylene in Manufacturing

Polyethylene, a versatile thermoplastic polymer, is widely used in manufacturing due to its chemical resistance and durability. Injection molding offers precise, high-volume production of complex polyethylene parts with tight tolerances, ideal for automotive and consumer goods. Rotational molding produces hollow, seamless polyethylene products with uniform wall thickness, commonly applied in large tanks and containers.

Overview of Injection Molding and Rotational Molding

Injection molding of polyethylene involves forcing molten polymer into a mold cavity under high pressure, enabling the production of complex, high-precision parts with fast cycle times and excellent surface finish. Rotational molding, also known as rotomolding, heats polyethylene powder within a hollow mold that is slowly rotated along two axes, resulting in uniform wall thickness and stress-free, hollow parts ideal for large, low-volume items. Each method offers distinct advantages in terms of part complexity, production volume, and mechanical properties tailored to specific polyethylene applications.

Material Compatibility: Polyethylene Grades for Molding

High-density polyethylene (HDPE) and linear low-density polyethylene (LLDPE) are widely compatible with injection molding due to their excellent flow properties and ability to produce precise, detailed parts. Low-density polyethylene (LDPE) suits rotational molding better, offering superior material distribution and flexibility for large, hollow products with fewer stress points. Both molding processes require careful selection of polyethylene grades for optimal thermal stability and mechanical performance during processing.

Process Comparison: Injection vs Rotational Molding

Injection molding of polyethylene offers high precision and rapid cycle times, ideal for producing complex, detailed parts with consistent wall thickness. Rotational molding, by contrast, excels in creating large, hollow, and seamless polyethylene products with uniform wall distribution, though it has longer production cycles. The choice between injection and rotational molding depends on part complexity, size, production volume, and cost-efficiency requirements.

Design Flexibility and Complexity

Injection molding enables high design flexibility with the production of intricate, precise polyethylene parts featuring complex geometries and tight tolerances. Rotational molding excels at creating large, hollow polyethylene components with uniform wall thickness but offers limited capability for fine details and complex surface features. Product design requirements, including complexity and size, determine the optimal molding process selection for polyethylene manufacturing.

Production Speed and Efficiency

Injection molding of polyethylene offers significantly higher production speeds, producing complex parts within seconds to minutes due to rapid cooling and automated cycles. Rotational molding, while slower with cycle times often ranging from 20 minutes to several hours, excels in manufacturing large, hollow, and low-stress parts with minimal material waste. Efficiency in injection molding is maximized by high-volume runs and precise material use, whereas rotational molding provides cost-effective solutions for low-volume, bulky items with intricate geometries.

Cost Analysis: Tooling, Labor, and Production

Injection molding of polyethylene involves high initial tooling costs due to the precision-metal molds but benefits from low labor expenses and rapid production cycles, making it cost-efficient for large-scale manufacturing. Rotational molding requires lower tooling investments with simpler molds, yet labor costs are higher because of longer cycle times and manual handling, which impacts overall production expenses. The choice between the two hinges on production volume and part complexity, with injection molding favored for mass production and rotational molding suited for lower volumes and larger, hollow components.

Product Quality and Surface Finish

Injection molding of polyethylene offers superior product quality with high dimensional accuracy and consistent surface finish, making it ideal for complex, detailed parts. Rotational molding provides a more uniform wall thickness and seamless construction but often results in a slightly rougher surface texture, suited for larger, hollow products. Surface finish in injection molding is smoother due to high-pressure injection and precise mold design, whereas rotational molding's finish is influenced by the cooling rate and mold surface.

Typical Applications for Each Molding Method

Injection molding of polyethylene is typically used for producing high-precision, small to medium-sized parts such as containers, automotive components, and household goods due to its fast cycle times and excellent surface finish. Rotational molding is preferred for manufacturing large, hollow, and complex items like tanks, playground equipment, and kayaks because it allows uniform wall thickness and stress-free parts. Each method's application hinges on product size, complexity, and production volume requirements.

Choosing the Right Molding Technique for Polyethylene Products

Injection molding suits polyethylene products requiring high precision and complex geometries, offering faster cycle times and superior surface finishes. Rotational molding is ideal for producing large, hollow, and low-stress polyethylene parts with uniform wall thickness and minimal material waste. Selecting the right molding technique depends on product design, production volume, and cost considerations to maximize polyethylene's performance and durability.

Injection Molding vs Rotational Molding Infographic

materialdif.com

materialdif.com