Blow molding polyethylene creates hollow, seamless containers with uniform wall thickness, ideal for bottles and large storage tanks due to its high production speed and repeatability. Rotational molding polyethylene produces larger, more complex shapes with thicker, sturdier walls, offering greater design flexibility and minimal material waste. Both techniques optimize the properties of polyethylene, but blow molding excels in rapid mass production while rotational molding suits custom, low-volume applications.

Table of Comparison

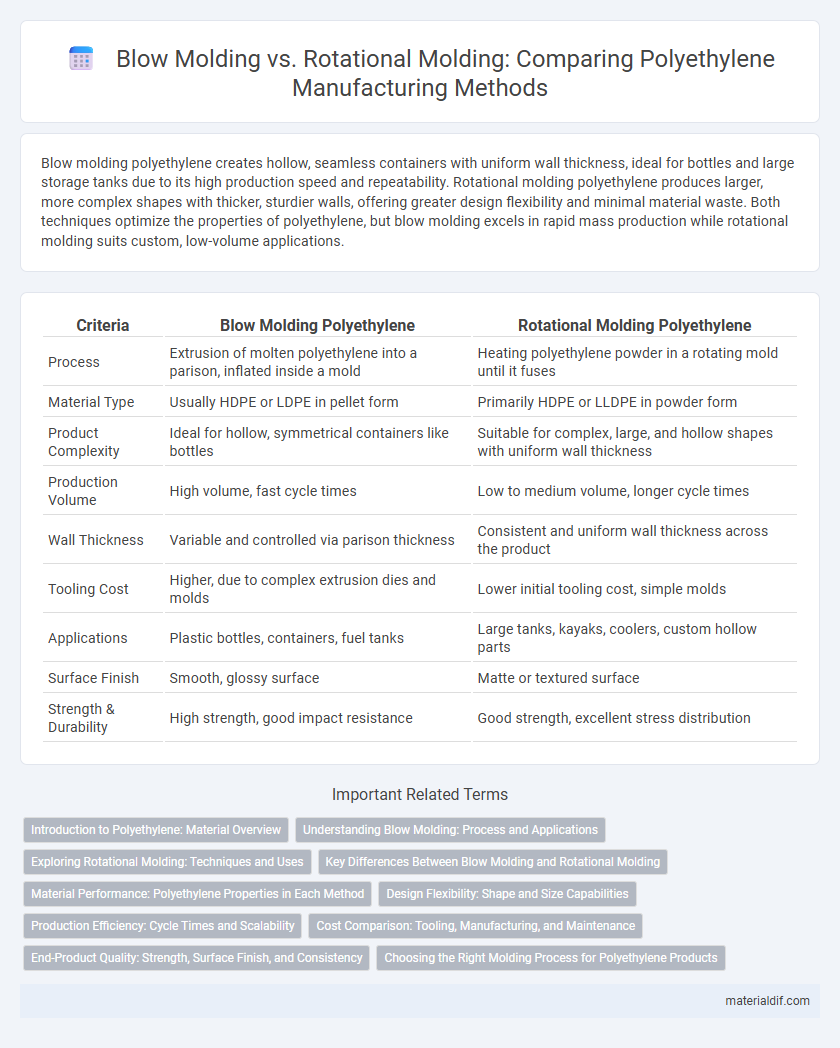

| Criteria | Blow Molding Polyethylene | Rotational Molding Polyethylene |

|---|---|---|

| Process | Extrusion of molten polyethylene into a parison, inflated inside a mold | Heating polyethylene powder in a rotating mold until it fuses |

| Material Type | Usually HDPE or LDPE in pellet form | Primarily HDPE or LLDPE in powder form |

| Product Complexity | Ideal for hollow, symmetrical containers like bottles | Suitable for complex, large, and hollow shapes with uniform wall thickness |

| Production Volume | High volume, fast cycle times | Low to medium volume, longer cycle times |

| Wall Thickness | Variable and controlled via parison thickness | Consistent and uniform wall thickness across the product |

| Tooling Cost | Higher, due to complex extrusion dies and molds | Lower initial tooling cost, simple molds |

| Applications | Plastic bottles, containers, fuel tanks | Large tanks, kayaks, coolers, custom hollow parts |

| Surface Finish | Smooth, glossy surface | Matte or textured surface |

| Strength & Durability | High strength, good impact resistance | Good strength, excellent stress distribution |

Introduction to Polyethylene: Material Overview

Polyethylene, a versatile thermoplastic polymer, is widely used in blow molding and rotational molding due to its excellent chemical resistance and flexibility. Blow molding creates hollow, seamless containers by inflating heated polyethylene resin inside a mold, ideal for high-volume production of bottles and tanks. Rotational molding, on the other hand, involves slowly rotating a heated mold filled with polyethylene powder, producing durable, stress-free parts with uniform wall thickness, suitable for large, complex shapes.

Understanding Blow Molding: Process and Applications

Blow molding polyethylene involves inflating heated plastic inside a mold to form hollow parts, making it ideal for producing containers, bottles, and tanks with uniform wall thickness. This process allows precise control over thickness and rapid production cycles, offering high efficiency for mass manufacturing. Common applications include packaging, automotive fuel tanks, and industrial drums where strength and lightweight characteristics are essential.

Exploring Rotational Molding: Techniques and Uses

Rotational molding of polyethylene involves heating powdered resin inside a mold that continuously rotates on two perpendicular axes, ensuring even material distribution and uniform wall thickness. This technique excels in producing large, hollow, and complex shapes such as tanks, kayaks, and automotive parts with minimal material waste and stress points. Its slow cooling process enhances polyethylene's impact resistance and chemical stability, making it ideal for durable, seamless products in various industries.

Key Differences Between Blow Molding and Rotational Molding

Blow molding polyethylene creates hollow, uniform shapes by inflating heated plastic inside a mold, offering fast production and high precision ideal for bottles and containers. Rotational molding polyethylene involves slowly rotating a heated mold with plastic powder to form thicker, stress-free parts, suited for large, complex, or hollow items like tanks and kayaks. Blow molding excels in high-volume, thin-walled products, while rotational molding provides design flexibility and cost-efficiency for low-volume, heavier-duty applications.

Material Performance: Polyethylene Properties in Each Method

Blow molding polyethylene typically produces parts with higher tensile strength and better impact resistance due to the material's orientation during the high-pressure air expansion process. Rotational molding polyethylene offers superior uniform wall thickness and enhanced stress distribution, resulting in improved durability and resistance to cracking. Both methods utilize polyethylene's inherent chemical resistance and low moisture absorption, but the chosen process significantly influences the final product's mechanical properties and performance in application-specific environments.

Design Flexibility: Shape and Size Capabilities

Blow molding polyethylene excels in producing hollow, uniform, and complex shapes with consistent wall thickness, making it ideal for containers and bottles that require precise dimensions. Rotational molding polyethylene offers superior design flexibility for larger, more intricate, and seamless hollow parts with varying wall thickness, suitable for tanks, bins, and custom-shaped items. This process allows for more freedom in size variation, accommodating both small and large-scale productions without the constraints of molds used in blow molding.

Production Efficiency: Cycle Times and Scalability

Blow molding polyethylene offers faster cycle times, typically completing production in a matter of seconds to minutes, making it highly efficient for large-scale manufacturing of hollow parts like bottles. Rotational molding polyethylene, while slower with cycle times often ranging from 20 to 60 minutes, excels in producing larger, more complex shapes with uniform wall thickness and minimal material stress. Scalability favors blow molding for mass production due to automation capabilities, whereas rotational molding suits smaller batches and customized, low-volume runs.

Cost Comparison: Tooling, Manufacturing, and Maintenance

Blow molding polyethylene typically incurs higher initial tooling costs due to the precision molds required, whereas rotational molding uses simpler, lower-cost molds but involves longer cycle times that can affect manufacturing expenses. Manufacturing costs for blow molding are generally lower per unit in high-volume production, while rotational molding is more cost-effective for low to medium volumes because it avoids the need for complex equipment and tooling changes. Maintenance costs tend to be higher in blow molding due to the wear on molds and machinery, while rotational molding equipment requires less frequent upkeep, contributing to lower ongoing expenses.

End-Product Quality: Strength, Surface Finish, and Consistency

Blow molding polyethylene produces hollow parts with excellent strength and a smooth surface finish, ideal for containers and bottles requiring uniform wall thickness. Rotational molding polyethylene offers superior consistency in wall thickness distribution and is well-suited for larger, complex shapes, though it may have a slightly rougher surface texture compared to blow molding. The choice between blow molding and rotational molding impacts end-product durability, aesthetic quality, and dimensional accuracy based on specific application requirements.

Choosing the Right Molding Process for Polyethylene Products

Blow molding polyethylene excels in producing hollow, uniform containers with high precision and rapid cycle times, ideal for bottles and drums. Rotational molding polyethylene offers superior design flexibility for large, complex shapes with consistent wall thickness but requires longer processing times. Selecting the right molding process depends on factors like product size, shape complexity, production volume, and mechanical property requirements of the polyethylene part.

Blow Molding Polyethylene vs Rotational Molding Polyethylene Infographic

materialdif.com

materialdif.com