Extrusion blow molding produces hollow polyethylene PET containers by inflating a heated parison within a mold, offering cost-effective manufacturing for larger and simpler shapes. Injection blow molding involves injecting molten PET into a preform mold, then reheating and expanding it inside a final mold, enabling higher precision and complex designs. Choosing between these methods depends on production volume, design complexity, and desired container properties.

Table of Comparison

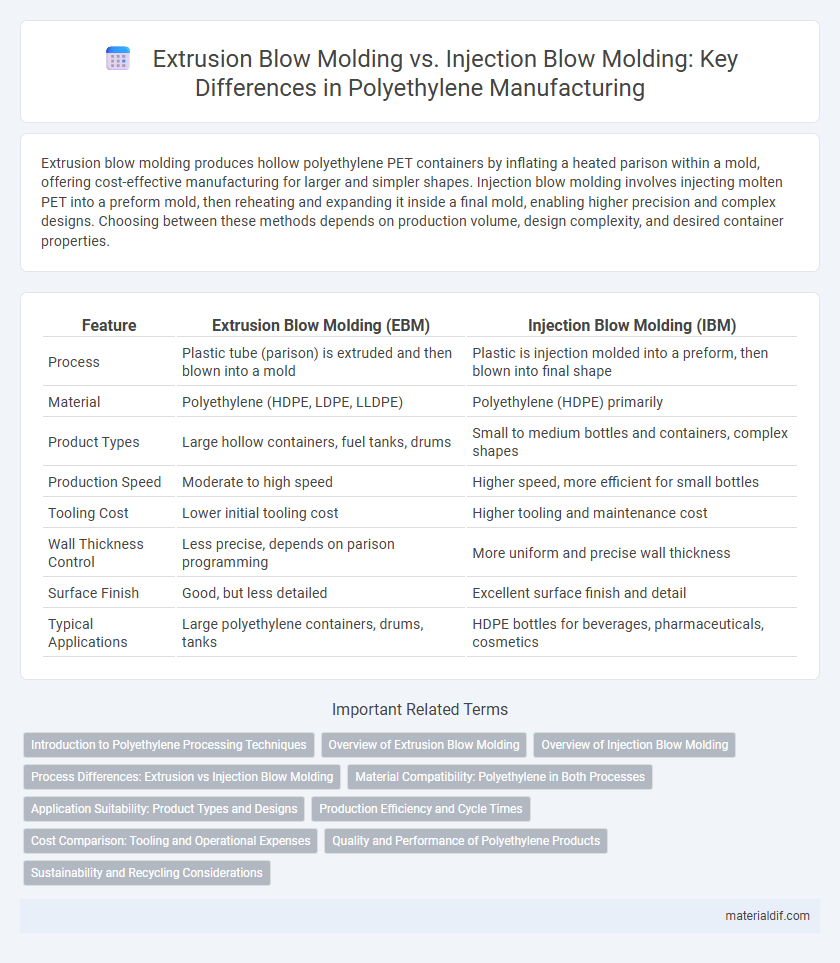

| Feature | Extrusion Blow Molding (EBM) | Injection Blow Molding (IBM) |

|---|---|---|

| Process | Plastic tube (parison) is extruded and then blown into a mold | Plastic is injection molded into a preform, then blown into final shape |

| Material | Polyethylene (HDPE, LDPE, LLDPE) | Polyethylene (HDPE) primarily |

| Product Types | Large hollow containers, fuel tanks, drums | Small to medium bottles and containers, complex shapes |

| Production Speed | Moderate to high speed | Higher speed, more efficient for small bottles |

| Tooling Cost | Lower initial tooling cost | Higher tooling and maintenance cost |

| Wall Thickness Control | Less precise, depends on parison programming | More uniform and precise wall thickness |

| Surface Finish | Good, but less detailed | Excellent surface finish and detail |

| Typical Applications | Large polyethylene containers, drums, tanks | HDPE bottles for beverages, pharmaceuticals, cosmetics |

Introduction to Polyethylene Processing Techniques

Extrusion blow molding shapes polyethylene by extruding a molten tube that is trapped in a mold and inflated to form hollow parts, ideal for large containers such as tanks and drums. Injection blow molding involves injecting molten polyethylene into a preform mold, then transferring it to a blow mold for inflation, producing precise, small to medium-sized hollow products like bottles. Both techniques optimize the processing of polyethylene by tailoring thickness and structural integrity according to the application requirements.

Overview of Extrusion Blow Molding

Extrusion Blow Molding (EBM) involves melting polyethylene resin and extruding it into a hollow tube called a parison, which is then clamped into a mold and inflated to form the desired shape. This process is ideal for producing hollow polyethylene products such as bottles, containers, and tanks with uniform wall thickness and complex geometries. EBM offers cost-effective manufacturing, high production rates, and flexibility in producing various sizes, making it a preferred choice for polyethylene packaging and industrial applications.

Overview of Injection Blow Molding

Injection Blow Molding (IBM) is a precise manufacturing process used to produce hollow polyethylene products with complex shapes and tight tolerances, ideal for medical and pharmaceutical containers. This method involves injection molding a preform, which is then transferred to a blow mold where compressed air expands it into its final shape, ensuring uniform wall thickness and high-quality surface finishes. IBM offers superior dimensional accuracy and material distribution compared to Extrusion Blow Molding, making it preferable for small to medium-sized polyethylene containers requiring detailed features.

Process Differences: Extrusion vs Injection Blow Molding

Extrusion blow molding involves melting polyethylene and extruding it into a hollow tube, or parison, which is then clamped into a mold and inflated to form the desired shape. Injection blow molding starts with injecting molten polyethylene into a preform mold, creating a biaxially oriented preform that is subsequently transferred to a blow mold for shaping. The key process difference lies in extrusion producing a parison directly, while injection blow molding creates a preform prior to blow molding, affecting part precision and material distribution.

Material Compatibility: Polyethylene in Both Processes

Polyethylene demonstrates excellent material compatibility in both extrusion blow molding and injection blow molding processes, performing well under the thermal and mechanical conditions specific to each method. In extrusion blow molding, polyethylene's flexibility and melt strength enable the formation of hollow containers with consistent wall thickness, while in injection blow molding, the polymer's ability to retain dimensional stability after injection ensures precise, high-quality parts. The material's chemical resistance and versatility make polyethylene a preferred choice for producing containers and bottles across various industries using both molding techniques.

Application Suitability: Product Types and Designs

Extrusion blow molding suits producing hollow polyethylene containers like large drums, fuel tanks, and medium to large bottles due to its ability to create seamless, uniform wall thickness in varied shapes. Injection blow molding excels in manufacturing small, precise, high-volume polyethylene bottles such as pharmaceutical containers and personal care packaging with complex neck finishes and tight tolerances. Choosing between these methods depends on product size, design complexity, and required wall uniformity for specific polyethylene applications.

Production Efficiency and Cycle Times

Extrusion blow molding (EBM) typically offers faster cycle times and higher production efficiency for large, hollow polyethylene products due to continuous parison extrusion and simplified mold clamping processes. Injection blow molding (IBM) provides superior precision and surface finish but involves longer cycle times caused by injection, blowing, and cooling phases. Manufacturers prioritize EBM for high-volume runs where speed and cost-effectiveness are critical, while IBM suits smaller, intricate polyethylene components requiring tighter tolerances.

Cost Comparison: Tooling and Operational Expenses

Extrusion blow molding typically requires lower initial tooling costs due to simpler die designs, making it more cost-effective for larger production runs of polyethylene products. Injection blow molding involves higher tooling expenses because of complex molds but offers greater precision and consistency for smaller, detailed polyethylene components. Operational expenses for extrusion blow molding remain lower due to faster cycle times, while injection blow molding may incur higher energy and maintenance costs linked to its intricate machinery.

Quality and Performance of Polyethylene Products

Extrusion Blow Molding produces polyethylene products with consistent wall thickness and excellent impact resistance, enhancing durability for applications like containers and bottles. Injection Blow Molding offers superior dimensional accuracy and surface finish, resulting in high-quality polyethylene parts ideal for precision medical and cosmetic containers. Both methods optimize polyethylene performance, but extrusion excels in strength while injection provides enhanced detail and uniformity.

Sustainability and Recycling Considerations

Extrusion blow molding (EBM) utilizes lower energy compared to injection blow molding (IBM), resulting in reduced carbon emissions during polyethylene container production. EBM facilitates easier recycling since it often produces single-layer, pure polyethylene structures, enhancing material recovery and reuse. IBM, although capable of intricate designs with multi-layer constructs, complicates recycling due to mixed materials and higher energy consumption.

Extrusion Blow Molding vs Injection Blow Molding Infographic

materialdif.com

materialdif.com