Plasticizer-free polyethylene (PE) offers enhanced chemical resistance and maintains its original mechanical strength, making it ideal for applications requiring durability and stability over time. Plasticized PE incorporates additives that increase flexibility and softness but may compromise long-term performance and environmental stability. Choosing between these types depends on the specific balance needed between rigidity and flexibility in polyethylene applications.

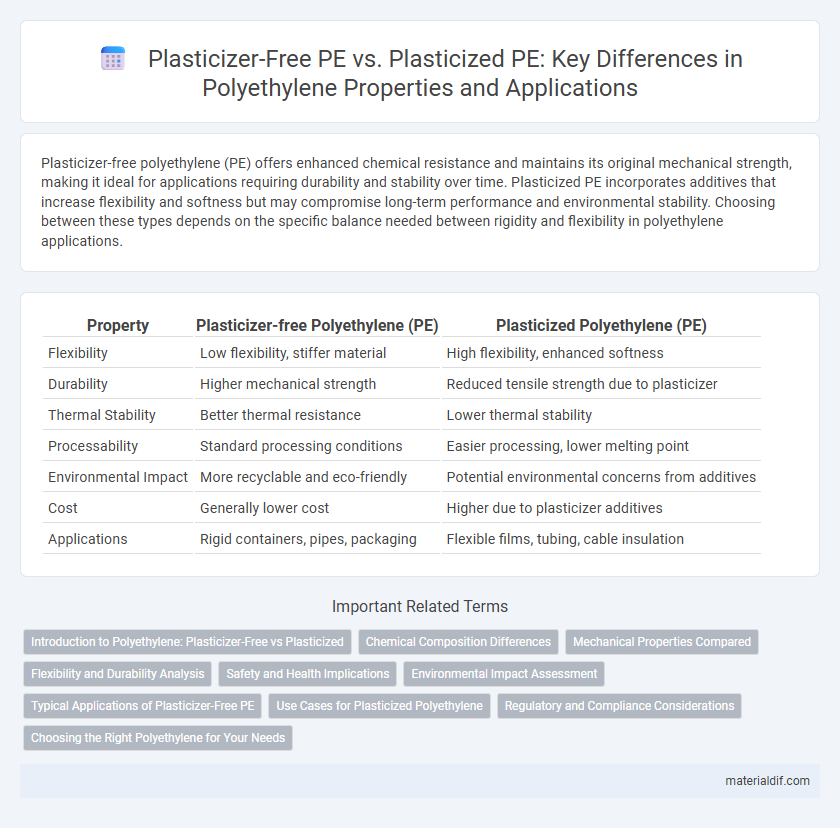

Table of Comparison

| Property | Plasticizer-free Polyethylene (PE) | Plasticized Polyethylene (PE) |

|---|---|---|

| Flexibility | Low flexibility, stiffer material | High flexibility, enhanced softness |

| Durability | Higher mechanical strength | Reduced tensile strength due to plasticizer |

| Thermal Stability | Better thermal resistance | Lower thermal stability |

| Processability | Standard processing conditions | Easier processing, lower melting point |

| Environmental Impact | More recyclable and eco-friendly | Potential environmental concerns from additives |

| Cost | Generally lower cost | Higher due to plasticizer additives |

| Applications | Rigid containers, pipes, packaging | Flexible films, tubing, cable insulation |

Introduction to Polyethylene: Plasticizer-Free vs Plasticized

Polyethylene (PE) is a versatile polymer widely used in packaging, construction, and consumer goods, available in plasticizer-free and plasticized forms that impact its flexibility and mechanical properties. Plasticizer-free PE maintains its inherent rigidity and chemical resistance, making it suitable for applications requiring durability and structural integrity. Plasticized PE incorporates additives to enhance flexibility and softness, enabling broader applications such as films and flexible tubing.

Chemical Composition Differences

Plasticizer-free polyethylene (PE) consists solely of polymer chains without added low-molecular-weight compounds, resulting in a more rigid and chemically stable structure. Plasticized PE contains plasticizers such as phthalates or adipates, which are integrated into the polymer matrix to increase flexibility by reducing intermolecular forces. The chemical composition difference lies in the presence of these plasticizer molecules, altering the thermal and mechanical properties of PE by enhancing chain mobility.

Mechanical Properties Compared

Plasticizer-free polyethylene (PE) exhibits higher tensile strength and stiffness compared to plasticized PE, which tends to show increased flexibility and elongation at break. The presence of plasticizers lowers the glass transition temperature, enhancing ductility but reducing overall mechanical resistance. Mechanical property optimization depends on the specific application requirements between rigidity and deformability.

Flexibility and Durability Analysis

Plasticizer-free polyethylene (PE) exhibits higher inherent durability due to its stable molecular structure, though it tends to be less flexible compared to plasticized PE. Plasticized PE incorporates additives that enhance flexibility by reducing intermolecular forces, which improves its pliability but can compromise long-term durability through potential plasticizer migration and environmental degradation. The balance between flexibility and durability in PE materials is critical for applications requiring sustained mechanical performance and resistance to environmental stressors.

Safety and Health Implications

Plasticizer-free polyethylene (PE) eliminates the risk of chemical leaching, reducing potential exposure to harmful additives that can disrupt endocrine functions and cause skin irritation. Plasticized PE contains additives that enhance flexibility but may release volatile organic compounds (VOCs) and phthalates, substances linked to reproductive toxicity and respiratory issues. Choosing plasticizer-free PE supports safer consumer products and minimizes environmental health hazards associated with plasticizer migration.

Environmental Impact Assessment

Plasticizer-free polyethylene (PE) demonstrates a lower environmental footprint due to the absence of added chemicals that can leach into ecosystems, reducing potential soil and water contamination. In contrast, plasticized PE contains additives that may contribute to microplastic pollution and increase toxicity risks for aquatic and terrestrial organisms. Life cycle assessments indicate plasticizer-free PE offers improved sustainability by minimizing hazardous waste generation and enhancing recyclability.

Typical Applications of Plasticizer-Free PE

Plasticizer-free polyethylene is widely used in food packaging, medical devices, and pharmaceutical applications where chemical purity and resistance to contamination are critical. Its inherent rigidity and stability make it ideal for manufacturing containers, tubing, and films that require high clarity and minimal additive migration. Unlike plasticized PE, it ensures enhanced safety and compliance with stringent regulatory standards for sensitive or high-purity applications.

Use Cases for Plasticized Polyethylene

Plasticized polyethylene is widely used in flexible packaging, wire and cable insulation, and automotive parts due to its enhanced flexibility and improved low-temperature performance. The addition of plasticizers increases the polymer's elongation and softness, making it suitable for applications that require pliability and resilience. These properties enable plasticized PE to outperform plasticizer-free PE in products demanding superior elasticity and impact resistance.

Regulatory and Compliance Considerations

Plasticizer-free polyethylene (PE) offers enhanced compliance with stringent regulatory standards due to the absence of additives that may leach or degrade, making it preferable for food packaging and medical applications governed by FDA and EU regulations. In contrast, plasticized PE contains additives that require specific compliance assessments under REACH and RoHS directives to ensure they do not pose health or environmental risks. The regulatory scrutiny of plasticizers often influences material selection in industries prioritizing safety and sustainability certifications.

Choosing the Right Polyethylene for Your Needs

Plasticizer-free polyethylene offers superior chemical resistance and dimensional stability, making it ideal for applications requiring durability and minimal deformation. Plasticized polyethylene, enhanced with additives for flexibility, suits products needing increased softness and impact resistance, such as hoses or packaging films. Selecting the right polyethylene depends on balancing rigidity and flexibility requirements tailored to the specific performance criteria of your project.

Plasticizer-free PE vs Plasticized PE Infographic

materialdif.com

materialdif.com