Polyethylene PET compounding involves chemically modifying the polymer by adding additives or masterbatches during processing to achieve specific performance characteristics, while blending physically mixes PET with other polymers or fillers without altering the chemical structure. Compounding ensures uniform dispersion and enhanced material properties, making it ideal for producing customized PET formulations. Blending, being simpler and more cost-effective, is often used for applications requiring basic property adjustments without significant performance enhancements.

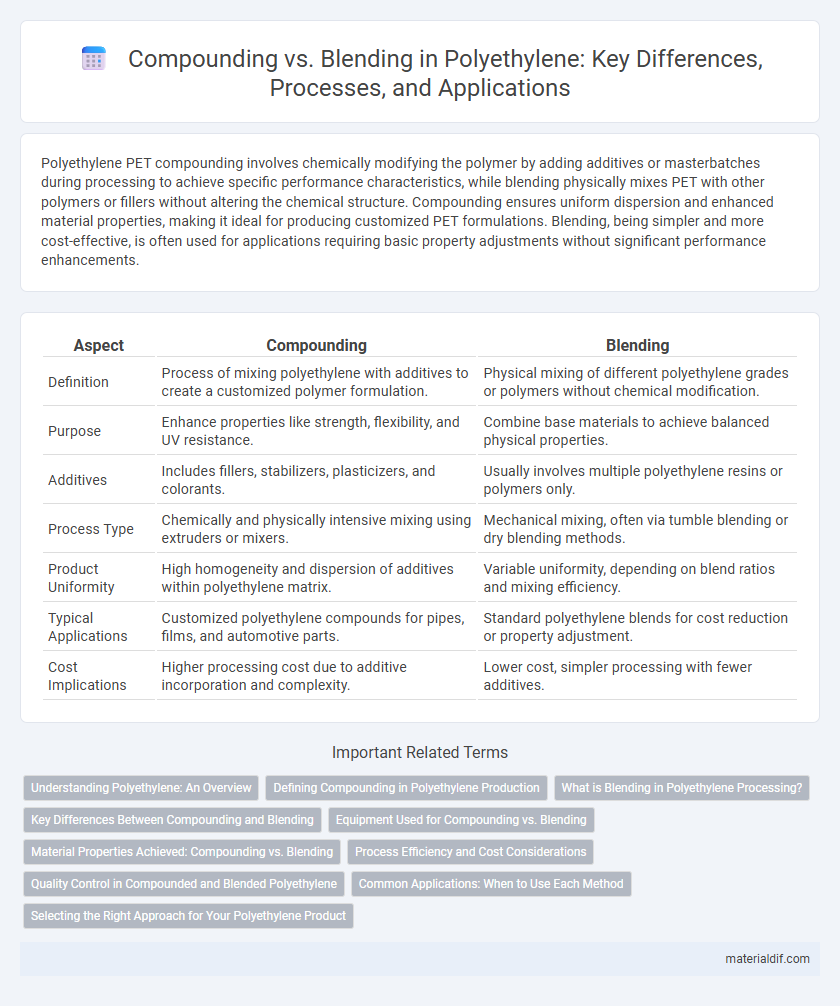

Table of Comparison

| Aspect | Compounding | Blending |

|---|---|---|

| Definition | Process of mixing polyethylene with additives to create a customized polymer formulation. | Physical mixing of different polyethylene grades or polymers without chemical modification. |

| Purpose | Enhance properties like strength, flexibility, and UV resistance. | Combine base materials to achieve balanced physical properties. |

| Additives | Includes fillers, stabilizers, plasticizers, and colorants. | Usually involves multiple polyethylene resins or polymers only. |

| Process Type | Chemically and physically intensive mixing using extruders or mixers. | Mechanical mixing, often via tumble blending or dry blending methods. |

| Product Uniformity | High homogeneity and dispersion of additives within polyethylene matrix. | Variable uniformity, depending on blend ratios and mixing efficiency. |

| Typical Applications | Customized polyethylene compounds for pipes, films, and automotive parts. | Standard polyethylene blends for cost reduction or property adjustment. |

| Cost Implications | Higher processing cost due to additive incorporation and complexity. | Lower cost, simpler processing with fewer additives. |

Understanding Polyethylene: An Overview

Polyethylene compounding involves the precise mixing of polymers with additives such as stabilizers, fillers, and colorants to enhance specific properties like impact resistance and UV stability. Blending, on the other hand, typically refers to the physical mixing of different grades or types of polyethylene, such as high-density polyethylene (HDPE) and low-density polyethylene (LDPE), to achieve a balance of mechanical and processing characteristics. Understanding the distinctions between compounding and blending is crucial for optimizing polyethylene performance in applications ranging from packaging to automotive components.

Defining Compounding in Polyethylene Production

Compounding in polyethylene production refers to the precise process of combining base polyethylene resin with additives such as fillers, stabilizers, plasticizers, and colorants to enhance specific properties like durability, flexibility, and UV resistance. This controlled formulation ensures consistent performance characteristics tailored for applications ranging from packaging films to automotive components. Unlike simple blending, compounding involves thorough mixing and often melting of ingredients to achieve homogeneous distribution and optimal material performance.

What is Blending in Polyethylene Processing?

Blending in polyethylene processing involves physically mixing two or more polyethylene resins or polymers to combine their properties without altering the molecular structure. This technique improves material characteristics such as impact resistance, flexibility, or processability by leveraging the intrinsic attributes of each polymer grade. Unlike compounding, blending does not require additives or extensive processing steps, making it a simpler and cost-effective method for modifying polyethylene performance.

Key Differences Between Compounding and Blending

Compounding polyethylene involves the precise mixing of polymers with additives like fillers, stabilizers, and colorants to enhance material properties and performance. Blending, on the other hand, refers to the physical mixing of two or more polymers without chemical modification, aiming to combine different polymer characteristics. Key differences include compounding's focus on creating tailored material formulations through additive incorporation, whereas blending primarily achieves property improvement by polymer combination without altering their chemical structure.

Equipment Used for Compounding vs. Blending

Compounding of polyethylene typically utilizes twin-screw extruders designed for intensive mixing, precise temperature control, and uniform dispersion of additives and fillers. Blending processes often rely on less complex equipment such as single-screw extruders or high-speed mixers, focusing on the homogeneous mixing of already compounded polymers. The choice of equipment directly impacts the material properties, with twin-screw extruders enabling enhanced melt homogeneity and filler distribution compared to conventional blending devices.

Material Properties Achieved: Compounding vs. Blending

Compounding of polyethylene involves the incorporation of additives, fillers, and reinforcements during the melt phase to achieve enhanced mechanical strength, chemical resistance, and thermal stability. Blending typically mixes different polymers or grades to modify physical properties like impact resistance and flexibility without significantly altering the molecular structure. Compounding delivers more uniform dispersion and tailored functionality, resulting in superior and predictable material behavior compared to the more heterogeneous outcomes of blending.

Process Efficiency and Cost Considerations

Polyethylene compounding involves the precise mixing of additives like stabilizers, fillers, and colorants at the molecular level, enhancing material properties and process efficiency, which often leads to higher upfront costs but improved product performance. Blending, however, simply mixes different polyethylene grades or polymers without chemical integration, offering lower initial costs and simpler processing but potentially inconsistent material behavior. Optimizing cost-effectiveness requires balancing compounding's superior uniformity and enhanced mechanical properties against blending's lower operational complexity and faster throughput.

Quality Control in Compounded and Blended Polyethylene

Quality control in compounded polyethylene involves rigorous testing for uniform dispersion of additives, ensuring consistent mechanical properties and thermal stability throughout the batch. In blended polyethylene, quality control focuses on achieving homogeneity of different polymer grades and verifying compatibility to prevent phase separation and maintain desired performance characteristics. Both processes require precise monitoring of key parameters such as melt flow index, tensile strength, and impact resistance to meet application-specific standards.

Common Applications: When to Use Each Method

Compounding polyethylene involves mixing polymers with additives such as fillers, stabilizers, and colorants to achieve specific performance characteristics, making it ideal for manufacturing high-impact packaging and automotive parts. Blending, which combines different polymer types or grades without significant chemical modification, suits applications like flexible films and molded household goods where balanced properties are essential. Choosing compounding or blending depends on the desired product attributes, processing requirements, and end-use conditions in industries like packaging, automotive, and consumer products.

Selecting the Right Approach for Your Polyethylene Product

Selecting the right approach for your polyethylene product hinges on understanding the distinct benefits of compounding and blending. Compounding involves intimately mixing polymers with additives at the molecular level, enhancing material properties such as impact resistance, UV stability, and color uniformity. Blending, by contrast, mixes different polyethylene grades to balance cost and performance but may result in less homogeneity and potential phase separation, making compounding the preferred choice for high-performance or specialized applications.

Compounding vs Blending Infographic

materialdif.com

materialdif.com