Crosslinked Polyethylene (PEX) offers enhanced chemical resistance, superior thermal stability, and improved mechanical strength compared to non-crosslinked polyethylene, making it ideal for high-performance applications such as plumbing and radiant heating systems. Non-crosslinked polyethylene, while more flexible and easier to process, lacks the durability and temperature resistance of PEX, limiting its use in demanding environments. The crosslinking process creates a three-dimensional network within the polymer matrix, increasing resistance to deformation and extending the material's lifespan.

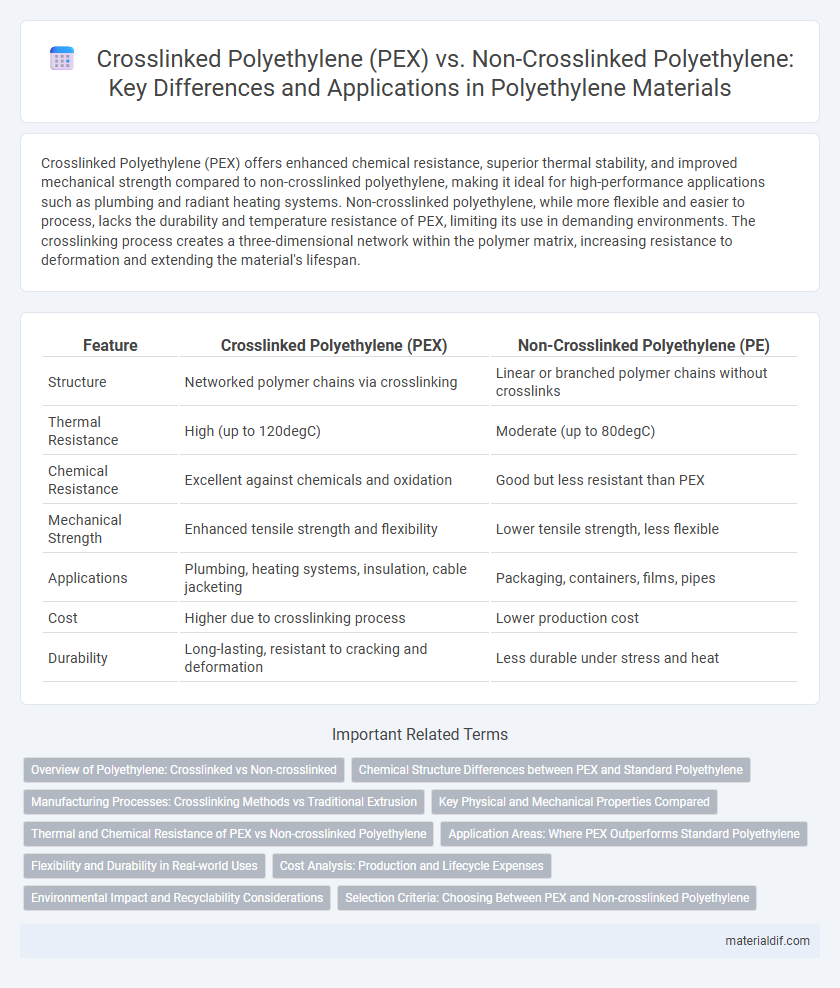

Table of Comparison

| Feature | Crosslinked Polyethylene (PEX) | Non-Crosslinked Polyethylene (PE) |

|---|---|---|

| Structure | Networked polymer chains via crosslinking | Linear or branched polymer chains without crosslinks |

| Thermal Resistance | High (up to 120degC) | Moderate (up to 80degC) |

| Chemical Resistance | Excellent against chemicals and oxidation | Good but less resistant than PEX |

| Mechanical Strength | Enhanced tensile strength and flexibility | Lower tensile strength, less flexible |

| Applications | Plumbing, heating systems, insulation, cable jacketing | Packaging, containers, films, pipes |

| Cost | Higher due to crosslinking process | Lower production cost |

| Durability | Long-lasting, resistant to cracking and deformation | Less durable under stress and heat |

Overview of Polyethylene: Crosslinked vs Non-crosslinked

Crosslinked polyethylene (PEX) undergoes a chemical process that creates a three-dimensional network of bonds, enhancing thermal resistance, mechanical strength, and chemical durability compared to non-crosslinked polyethylene. Non-crosslinked polyethylene, typically in forms like LDPE and HDPE, lacks these crosslinks, resulting in materials with lower heat resistance and tensile strength but greater flexibility and ease of processing. The crosslinking in PEX significantly improves its application in plumbing, heating, and electrical insulation, where higher temperature tolerance and durability are crucial.

Chemical Structure Differences between PEX and Standard Polyethylene

Crosslinked Polyethylene (PEX) features a network of covalent bonds connecting individual polymer chains, enhancing thermal resistance, mechanical strength, and chemical stability compared to standard Polyethylene (PE), which consists of linear or branched polymer chains without crosslinking. This crosslinking process alters the molecular architecture, reducing chain mobility and improving durability against heat, pressure, and environmental stress cracking. Standard Polyethylene, such as High-Density Polyethylene (HDPE) or Low-Density Polyethylene (LDPE), lacks these chemical bridges, resulting in lower structural integrity and performance under demanding conditions.

Manufacturing Processes: Crosslinking Methods vs Traditional Extrusion

Crosslinked Polyethylene (PEX) undergoes specialized crosslinking methods such as peroxide crosslinking, silane crosslinking, or electron beam irradiation, which enhance its thermal stability and mechanical strength by creating covalent bonds between polymer chains. In contrast, non-crosslinked polyethylene is produced primarily through traditional extrusion processes, where molten polymer is shaped without additional chemical modifications, resulting in lower resistance to heat and stress. The distinct manufacturing processes directly impact the material properties, with PEX offering superior durability for applications in plumbing and electrical insulation compared to conventional polyethylene.

Key Physical and Mechanical Properties Compared

Crosslinked polyethylene (PEX) exhibits superior thermal resistance, higher tensile strength, and improved chemical stability compared to non-crosslinked polyethylene, making it more suitable for plumbing and heating applications. Non-crosslinked polyethylene, including HDPE and LDPE, generally offers greater flexibility and easier processability but lower resistance to deformation under heat and pressure. The crosslinking process enhances PEX's durability, reducing its susceptibility to environmental stress cracking and increasing its lifespan in demanding environments.

Thermal and Chemical Resistance of PEX vs Non-crosslinked Polyethylene

Crosslinked Polyethylene (PEX) exhibits superior thermal resistance, withstanding temperatures up to 120-135degC compared to non-crosslinked polyethylene, which typically deforms above 80-90degC. In chemical resistance, PEX demonstrates enhanced durability against oxidizing agents, oils, and solvents, reducing degradation and prolonging service life in harsh environments. The crosslinking process creates a three-dimensional molecular network in PEX, significantly increasing its resistance to thermal stress and chemical attack relative to its non-crosslinked counterpart.

Application Areas: Where PEX Outperforms Standard Polyethylene

Crosslinked polyethylene (PEX) excels in plumbing and heating systems due to its superior thermal resistance and flexibility compared to non-crosslinked polyethylene, which is prone to deformation under high temperatures. PEX's enhanced chemical and mechanical stability make it the preferred choice for radiant floor heating, potable water piping, and industrial fluid transport applications. Standard polyethylene remains suitable for packaging and insulation but cannot withstand the rigorous demands of high-pressure or high-temperature environments where PEX outperforms.

Flexibility and Durability in Real-world Uses

Crosslinked polyethylene (PEX) exhibits superior flexibility and enhanced durability compared to non-crosslinked polyethylene, making it ideal for applications requiring resistance to high pressure and temperature fluctuations, such as plumbing and radiant heating systems. The crosslinking process creates a three-dimensional network that significantly improves impact resistance, chemical stability, and thermal endurance in real-world conditions. Non-crosslinked polyethylene, although less costly and easier to process, lacks the robustness needed for demanding environments, often resulting in reduced lifespan and increased susceptibility to deformation under stress.

Cost Analysis: Production and Lifecycle Expenses

Crosslinked Polyethylene (PEX) incurs higher initial production costs due to crosslinking processes such as chemical, silane, or radiation methods, which enhance thermal and mechanical properties. Non-crosslinked polyethylene features lower manufacturing expenses but may experience shorter lifecycle performance, leading to increased maintenance and replacement costs over time. Lifecycle cost analysis favors PEX in applications requiring durability under high temperature and pressure, despite its upfront cost premium.

Environmental Impact and Recyclability Considerations

Crosslinked Polyethylene (PEX) exhibits enhanced thermal and chemical resistance due to its three-dimensional network structure, but its crosslinked bonds hinder recyclability, often requiring specialized disposal methods that may contribute to environmental challenges. Non-crosslinked polyethylene, such as HDPE and LDPE, offers greater ease of recycling through mechanical processes, supporting circular economy initiatives and reducing landfill waste. Environmental impact assessments favor non-crosslinked polyethylene for sustainable applications, while PEX's durability may reduce replacement frequency, balancing its overall environmental footprint.

Selection Criteria: Choosing Between PEX and Non-crosslinked Polyethylene

PEX offers superior chemical resistance, enhanced thermal stability, and greater mechanical strength compared to non-crosslinked polyethylene, making it ideal for high-temperature plumbing and radiant heating applications. Non-crosslinked polyethylene is typically preferred for applications requiring flexibility and low-cost material, such as packaging or tubing for low-pressure environments. Selection criteria should prioritize operating temperature, pressure requirements, chemical exposure, and budget constraints to determine the appropriate polyethylene type.

Crosslinked Polyethylene (PEX) vs Non-crosslinked Polyethylene Infographic

materialdif.com

materialdif.com