Ethylene copolymer polyethylene incorporates comonomers to enhance flexibility and impact resistance, making it ideal for applications requiring durability and toughness. Homopolymer polyethylene consists solely of ethylene units, resulting in higher density and stiffness suitable for rigid packaging and containers. Choosing between copolymer and homopolymer polyethylene depends on the desired balance between mechanical properties and processing requirements in polyethylene PET products.

Table of Comparison

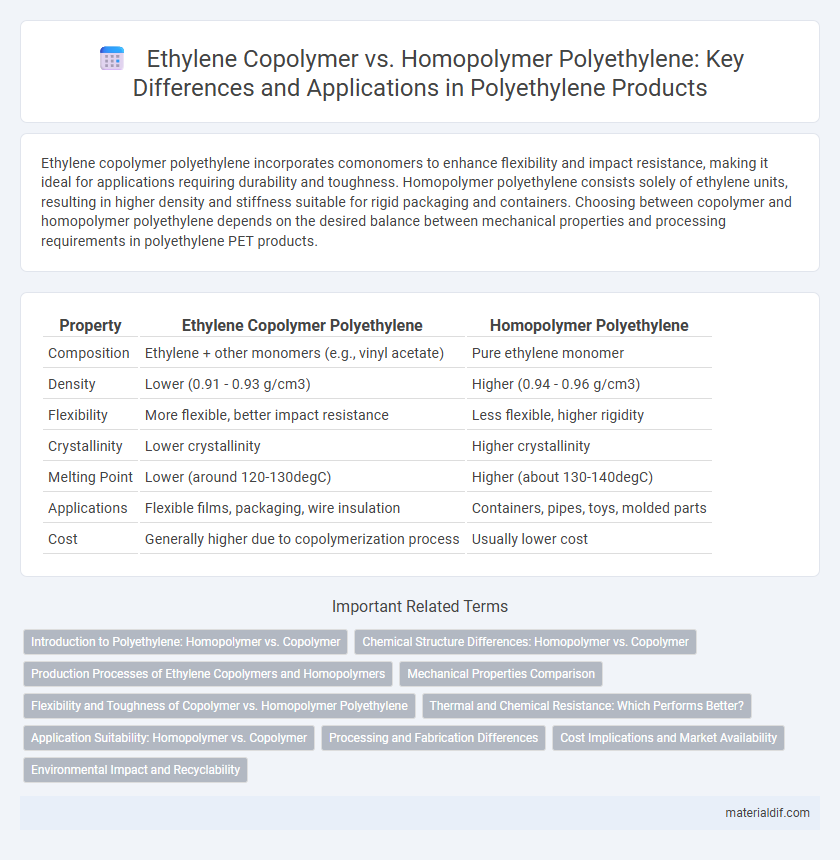

| Property | Ethylene Copolymer Polyethylene | Homopolymer Polyethylene |

|---|---|---|

| Composition | Ethylene + other monomers (e.g., vinyl acetate) | Pure ethylene monomer |

| Density | Lower (0.91 - 0.93 g/cm3) | Higher (0.94 - 0.96 g/cm3) |

| Flexibility | More flexible, better impact resistance | Less flexible, higher rigidity |

| Crystallinity | Lower crystallinity | Higher crystallinity |

| Melting Point | Lower (around 120-130degC) | Higher (about 130-140degC) |

| Applications | Flexible films, packaging, wire insulation | Containers, pipes, toys, molded parts |

| Cost | Generally higher due to copolymerization process | Usually lower cost |

Introduction to Polyethylene: Homopolymer vs. Copolymer

Polyethylene consists of two main types: homopolymer and copolymer, each distinguished by their polymerization process and molecular structure. Homopolymer polyethylene is composed of only ethylene monomers, offering high density, rigidity, and tensile strength, ideal for containers and pipes. Ethylene copolymer polyethylene includes comonomers like butene or hexene, enhancing flexibility, impact resistance, and low-temperature performance, commonly used in packaging and films.

Chemical Structure Differences: Homopolymer vs. Copolymer

Ethylene homopolymer polyethylene consists of a simple, repeating chain of ethylene monomers, resulting in a highly crystalline structure with uniform properties. In contrast, ethylene copolymer polyethylene incorporates comonomers such as 1-butene, 1-hexene, or 1-octene into the polymer chain, disrupting crystallinity and enhancing flexibility and impact resistance. The introduction of comonomers lowers the density and crystallinity compared to homopolymers, enabling tailored mechanical and thermal properties for diverse applications.

Production Processes of Ethylene Copolymers and Homopolymers

Ethylene copolymers are produced through copolymerization of ethylene with other alpha-olefins like butene or hexene, using techniques such as Ziegler-Natta or metallocene catalysis to control branching and density. Homopolymer polyethylene is synthesized via polymerization of pure ethylene monomers, commonly utilizing high-pressure radical polymerization for low-density polyethylene (LDPE) or catalytic processes for high-density polyethylene (HDPE). The choice of catalysts and polymerization conditions directly influences molecular weight distribution, crystallinity, and material properties in both ethylene copolymers and homopolymers.

Mechanical Properties Comparison

Ethylene copolymer polyethylene typically exhibits enhanced impact resistance and flexibility compared to homopolymer polyethylene due to the incorporation of comonomers like butene or hexene, which disrupt crystal packing and reduce stiffness. Homopolymer polyethylene, composed solely of ethylene units, offers higher tensile strength and rigidity because of its more uniform and crystalline structure. The mechanical properties of copolymers make them suitable for applications requiring toughness and elongation, while homopolymers are preferred where strength and hardness are critical.

Flexibility and Toughness of Copolymer vs. Homopolymer Polyethylene

Ethylene copolymer polyethylene exhibits enhanced flexibility and toughness compared to homopolymer polyethylene due to its incorporation of comonomers like butene or hexene, which disrupt the linear structure and increase chain mobility. This molecular architecture in copolymers results in improved impact resistance and elongation properties, making them ideal for applications requiring durability under stress. In contrast, homopolymer polyethylene's highly crystalline structure provides higher stiffness but lower flexibility, limiting its performance in dynamic or flexible environments.

Thermal and Chemical Resistance: Which Performs Better?

Ethylene copolymer polyethylene generally exhibits superior chemical resistance and enhanced flexibility compared to homopolymer polyethylene, due to the incorporation of comonomers like butene or hexene that disrupt crystallinity. Homopolymer polyethylene, characterized by higher crystallinity, achieves greater thermal resistance, maintaining structural integrity under elevated temperatures. Selecting between ethylene copolymer and homopolymer polyethylene depends on application-specific requirements for chemical exposure and thermal stability.

Application Suitability: Homopolymer vs. Copolymer

Homopolymer polyethylene offers high tensile strength and stiffness, making it ideal for rigid packaging, containers, and plastic parts requiring durability. Ethylene copolymer polyethylene, with enhanced flexibility and impact resistance, suits applications like film wraps, squeeze bottles, and impact-modified molded products. Selecting between homopolymer and copolymer polyethylene depends on the balance of mechanical properties needed for specific industrial and consumer applications.

Processing and Fabrication Differences

Ethylene copolymer polyethylene exhibits enhanced flexibility and processability compared to homopolymer polyethylene due to the incorporation of comonomers, which disrupt crystallinity and lower melting points. Homopolymer polyethylene typically requires higher processing temperatures and exhibits increased stiffness, making it suitable for applications demanding rigidity and tensile strength. Fabrication of copolymers involves extrusion and molding techniques adapted to manage lower viscosity and improved impact resistance, while homopolymers benefit from more straightforward thermal processing with slower cooling rates to maximize crystalline structure.

Cost Implications and Market Availability

Ethylene copolymer polyethylene generally incurs higher production costs than homopolymer polyethylene due to the complexity of incorporating comonomers, affecting overall pricing structures in the plastic industry. Homopolymer polyethylene, produced from a single monomer type, offers greater market availability and lower cost, making it the preferred choice for applications requiring high density and stiffness. The balance between cost efficiency and material properties influences procurement decisions in sectors such as packaging and automotive manufacturing.

Environmental Impact and Recyclability

Ethylene copolymer polyethylene, such as polyethylene terephthalate (PET) blends, generally exhibit enhanced material properties but complicate recycling due to mixed polymer chains that require specialized processing techniques. Homopolymer polyethylene, primarily composed of high-density polyethylene (HDPE) or low-density polyethylene (LDPE), offers simpler recyclability with established recovery streams and lower environmental impact from recycling operations. The environmental footprint of ethylene copolymers often includes higher energy consumption and more complex separation systems, while homopolymers benefit from widespread infrastructure supporting efficient reuse and reduced landfill contribution.

Ethylene Copolymer vs Homopolymer Polyethylene Infographic

materialdif.com

materialdif.com