Extrusion grade polyethylene PET is specifically formulated for processing methods like injection molding and blow molding, offering excellent thermal stability and mechanical strength. Film grade polyethylene PET is optimized for producing thin, flexible films with enhanced clarity, sealability, and barrier properties. Selecting the appropriate grade ensures optimal performance and product quality based on the intended manufacturing process and application.

Table of Comparison

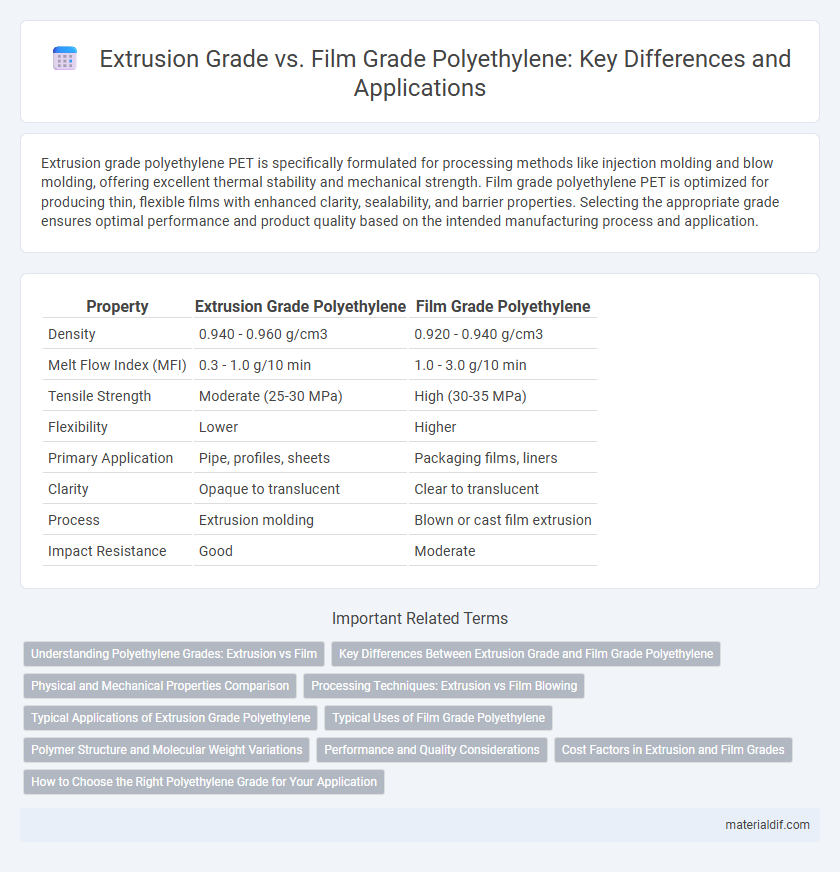

| Property | Extrusion Grade Polyethylene | Film Grade Polyethylene |

|---|---|---|

| Density | 0.940 - 0.960 g/cm3 | 0.920 - 0.940 g/cm3 |

| Melt Flow Index (MFI) | 0.3 - 1.0 g/10 min | 1.0 - 3.0 g/10 min |

| Tensile Strength | Moderate (25-30 MPa) | High (30-35 MPa) |

| Flexibility | Lower | Higher |

| Primary Application | Pipe, profiles, sheets | Packaging films, liners |

| Clarity | Opaque to translucent | Clear to translucent |

| Process | Extrusion molding | Blown or cast film extrusion |

| Impact Resistance | Good | Moderate |

Understanding Polyethylene Grades: Extrusion vs Film

Extrusion grade polyethylene is engineered for processes requiring high melt strength and uniform flow to create products like pipes, sheets, and profiles with excellent mechanical properties. Film grade polyethylene offers enhanced clarity, flexibility, and sealability, optimized for thin, durable packaging films used in food wrapping and industrial applications. Understanding these grades involves evaluating their molecular weight distribution and additives, which influence the processing behavior and end-use performance.

Key Differences Between Extrusion Grade and Film Grade Polyethylene

Extrusion grade polyethylene, characterized by higher molecular weight and density, offers superior mechanical strength and is ideal for producing rigid, durable products like pipes and sheets. Film grade polyethylene features lower molecular weight and improved clarity, flexibility, and sealability, making it optimal for thin, transparent packaging films and bags. The key differences lie in molecular structure, processing methods, and end-use applications, impacting physical properties such as tensile strength, flexibility, and barrier performance.

Physical and Mechanical Properties Comparison

Extrusion grade polyethylene typically exhibits higher melt flow index (MFI) values, enabling easier processing through extrusion equipment, while film grade polyethylene offers superior tensile strength and elongation properties ideal for flexible packaging applications. The molecular weight distribution in film grade is narrower, enhancing clarity and impact resistance, whereas extrusion grades have broader distributions to improve melt viscosity and processability. Density and crystallinity differences also contribute to film grade polyethylene's enhanced flexibility and toughness compared to the more rigid extrusion grade.

Processing Techniques: Extrusion vs Film Blowing

Extrusion grade polyethylene is specifically formulated for melt extrusion processes, where the polymer is melted and shaped through a die to create solid profiles, sheets, or pipes with uniform thickness and high mechanical strength. Film grade polyethylene, on the other hand, is optimized for film blowing techniques, producing thin, flexible films by inflating a molten polymer tube to form bubbles, which results in films with high clarity, elongation, and sealability. The molecular weight distribution and melt flow index differ significantly between the two grades, influencing their processing behavior and final product properties in extrusion and film blowing applications.

Typical Applications of Extrusion Grade Polyethylene

Extrusion grade polyethylene is primarily used in manufacturing pipes, profiles, and sheets, offering excellent processing characteristics for rigid and semi-rigid products. Its high melt strength and viscosity make it ideal for applications requiring dimensional stability, such as tubing, wire coatings, and geomembranes. This grade supports heavy-duty uses where durability and impact resistance are critical, distinguishing it from the more flexible film grade polyethylene commonly used in packaging films and bags.

Typical Uses of Film Grade Polyethylene

Film grade polyethylene is primarily used in packaging applications such as plastic bags, shrink films, and agricultural films due to its excellent clarity, flexibility, and moisture barrier properties. It is engineered to provide superior sealability and processability in blown or cast film extrusion, making it ideal for food wrap and protective coverings. Unlike extrusion grade polyethylene, film grade offers enhanced toughness and puncture resistance suitable for flexible film applications.

Polymer Structure and Molecular Weight Variations

Extrusion grade polyethylene typically features a higher molecular weight with a broader molecular weight distribution, enhancing melt strength and processability for applications like pipe and profile extrusion. Film grade polyethylene, in contrast, exhibits a narrower molecular weight distribution and a more linear polymer structure, optimizing clarity, flexibility, and mechanical properties critical for film applications. Variations in branching and polymer chain length directly influence the polymer's rheological behavior, impacting extrusion stability and film performance.

Performance and Quality Considerations

Extrusion grade polyethylene offers superior melt strength and thermal stability, making it ideal for producing complex profiles, pipes, and sheets with consistent dimensional accuracy and surface finish. Film grade polyethylene is engineered for enhanced clarity, flexibility, and tensile strength, ensuring optimal performance in packaging applications requiring durability, puncture resistance, and transparency. Quality considerations for extrusion grade emphasize uniformity in melt index and impact resistance, while film grade prioritizes improved elongation properties and sealability to meet stringent packaging standards.

Cost Factors in Extrusion and Film Grades

Extrusion grade polyethylene typically incurs lower raw material costs due to its broader molecular weight distribution, which enhances processing flexibility and reduces the need for costly additives. Film grade polyethylene demands higher purity and narrower molecular weight distribution for superior clarity and strength, resulting in increased production expenses and raw material premiums. Cost efficiency in extrusion grades is driven by energy savings and faster throughput, whereas film grades prioritize quality, impacting overall manufacturing costs significantly.

How to Choose the Right Polyethylene Grade for Your Application

Selecting the right polyethylene grade depends on the specific application requirements, such as flexibility, strength, and processing method. Extrusion grade polyethylene is ideal for producing rigid products and tubing due to its higher density and melt strength, while film grade polyethylene offers superior clarity, flexibility, and sealability for packaging films. Evaluating factors like mechanical properties, thickness, and end-use environment ensures optimal performance and cost-efficiency in choosing between extrusion and film grade polyethylene.

Extrusion grade vs Film grade Infographic

materialdif.com

materialdif.com