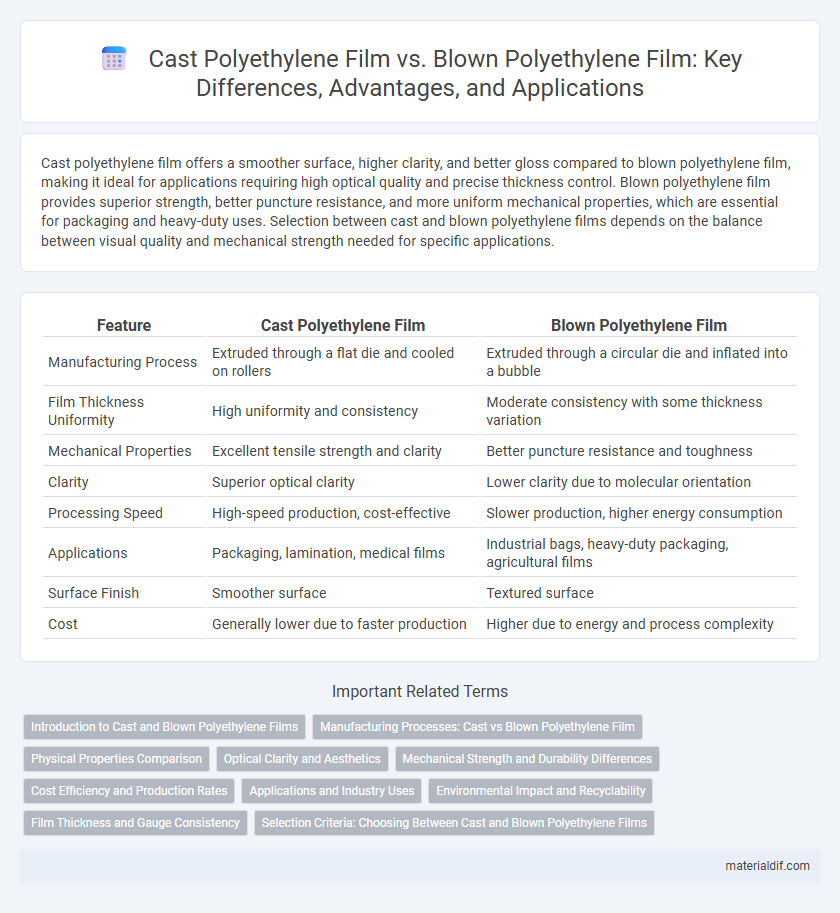

Cast polyethylene film offers a smoother surface, higher clarity, and better gloss compared to blown polyethylene film, making it ideal for applications requiring high optical quality and precise thickness control. Blown polyethylene film provides superior strength, better puncture resistance, and more uniform mechanical properties, which are essential for packaging and heavy-duty uses. Selection between cast and blown polyethylene films depends on the balance between visual quality and mechanical strength needed for specific applications.

Table of Comparison

| Feature | Cast Polyethylene Film | Blown Polyethylene Film |

|---|---|---|

| Manufacturing Process | Extruded through a flat die and cooled on rollers | Extruded through a circular die and inflated into a bubble |

| Film Thickness Uniformity | High uniformity and consistency | Moderate consistency with some thickness variation |

| Mechanical Properties | Excellent tensile strength and clarity | Better puncture resistance and toughness |

| Clarity | Superior optical clarity | Lower clarity due to molecular orientation |

| Processing Speed | High-speed production, cost-effective | Slower production, higher energy consumption |

| Applications | Packaging, lamination, medical films | Industrial bags, heavy-duty packaging, agricultural films |

| Surface Finish | Smoother surface | Textured surface |

| Cost | Generally lower due to faster production | Higher due to energy and process complexity |

Introduction to Cast and Blown Polyethylene Films

Cast polyethylene film is produced by extruding molten polymer onto a chilled roller, creating a uniform thickness and smooth surface ideal for packaging applications requiring clarity and gloss. Blown polyethylene film is made by extruding molten polymer through a circular die and inflating it into a bubble, resulting in enhanced strength and flexibility suited for industrial uses like agricultural films and heavy-duty bags. Both cast and blown films offer distinct advantages in terms of mechanical properties, surface finish, and production efficiency depending on end-use requirements.

Manufacturing Processes: Cast vs Blown Polyethylene Film

Cast polyethylene film is produced by extruding molten resin onto a chilled roller, which rapidly cools the film to create a smooth, uniform surface with high clarity and excellent dimensional stability. Blown polyethylene film is manufactured by extruding molten resin through a circular die to form a tubular bubble that is cooled by air, resulting in a film with better stretch properties and higher impact resistance but lower clarity. The cast process allows for faster production speeds and precise thickness control, whereas the blown process offers enhanced mechanical strength and flexibility for applications like packaging and agricultural films.

Physical Properties Comparison

Cast polyethylene film exhibits superior clarity, uniform thickness, and higher tensile strength due to its cooling process on a chilled roller, resulting in a denser, more consistent molecular structure. Blown polyethylene film offers better cross-directional strength and flexibility because of its bubble expansion method, allowing for greater elongation and impact resistance. The choice between cast and blown films depends on specific application requirements such as transparency, mechanical strength, and stretchability.

Optical Clarity and Aesthetics

Cast polyethylene film offers superior optical clarity and a smoother, glossier surface compared to blown polyethylene film, making it ideal for applications requiring high-quality visual appeal. The cast process produces a more uniform film with less haze, enhancing transparency and color vibrancy. Blown polyethylene film, while more cost-effective and durable, typically exhibits higher haze and a matte finish, which can reduce aesthetic quality.

Mechanical Strength and Durability Differences

Cast polyethylene film exhibits superior mechanical strength due to its uniform thickness and higher tensile properties, resulting from the controlled cooling process during production. Blown polyethylene film, while generally offering enhanced puncture resistance and durability from its biaxial orientation, tends to have slightly lower tensile strength and is more prone to gauge variability. These mechanical and durability differences make cast films ideal for applications requiring consistent strength and blown films better suited for flexible packaging demanding toughness and abrasion resistance.

Cost Efficiency and Production Rates

Cast polyethylene film offers superior cost efficiency due to lower energy consumption and faster cooling times in its production process, resulting in higher production rates compared to blown polyethylene film. The blown film process involves multiple steps with slower cooling, which increases manufacturing costs and limits output speed. Manufacturers targeting high-volume, cost-effective production typically prefer cast film for applications requiring consistent gauge and clarity.

Applications and Industry Uses

Cast polyethylene film offers superior clarity and uniform thickness, making it ideal for high-quality packaging in food, medical, and electronics industries. Blown polyethylene film provides enhanced strength and puncture resistance, suitable for heavy-duty applications like construction sheeting, agricultural covers, and industrial packaging. Both variants serve critical roles in flexible packaging, with cast film favored for printability and blown film chosen for durability and cost-effectiveness.

Environmental Impact and Recyclability

Cast polyethylene film typically has a thinner gauge and smoother surface, resulting in less material usage and easier recyclability compared to blown polyethylene film, which involves higher energy consumption due to its extrusion process. Blown film, however, offers superior strength and puncture resistance but can be more challenging to recycle because of its thicker, less uniform layers. Environmentally, cast film production generates lower carbon emissions and waste, contributing to a smaller ecological footprint than blown film manufacturing.

Film Thickness and Gauge Consistency

Cast polyethylene film offers superior gauge consistency with thickness typically ranging from 0.5 mil to 10 mil, achieved through a controlled cooling process that results in uniform film properties. Blown polyethylene film generally varies in thickness from 0.5 mil to 6 mil but exhibits less uniformity due to rapid cooling and stretching during production, leading to gauge variations. Precise control of film thickness and gauge consistency in cast film makes it ideal for applications requiring high optical clarity and dimensional stability.

Selection Criteria: Choosing Between Cast and Blown Polyethylene Films

Selection between cast and blown polyethylene films primarily depends on desired film properties and application needs. Cast polyethylene film offers superior clarity, uniform thickness, and better gloss, ideal for high-quality packaging and printed materials. Blown polyethylene film provides greater tensile strength, better puncture resistance, and enhanced stretchability, making it suitable for heavy-duty packaging and industrial uses.

Cast Polyethylene Film vs Blown Polyethylene Film Infographic

materialdif.com

materialdif.com