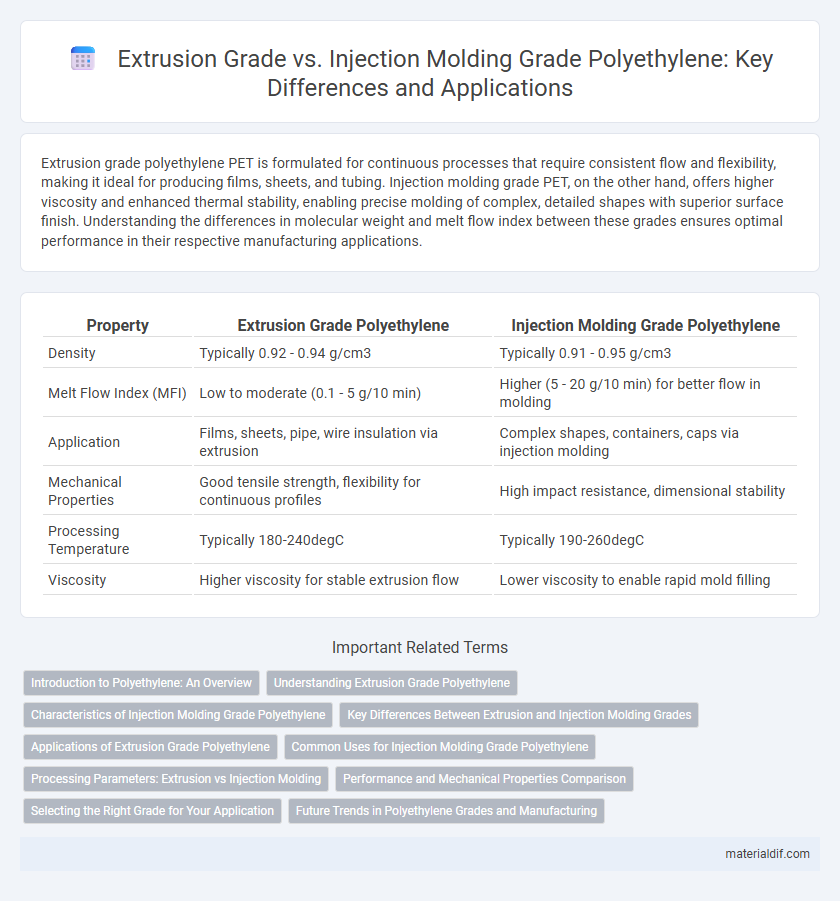

Extrusion grade polyethylene PET is formulated for continuous processes that require consistent flow and flexibility, making it ideal for producing films, sheets, and tubing. Injection molding grade PET, on the other hand, offers higher viscosity and enhanced thermal stability, enabling precise molding of complex, detailed shapes with superior surface finish. Understanding the differences in molecular weight and melt flow index between these grades ensures optimal performance in their respective manufacturing applications.

Table of Comparison

| Property | Extrusion Grade Polyethylene | Injection Molding Grade Polyethylene |

|---|---|---|

| Density | Typically 0.92 - 0.94 g/cm3 | Typically 0.91 - 0.95 g/cm3 |

| Melt Flow Index (MFI) | Low to moderate (0.1 - 5 g/10 min) | Higher (5 - 20 g/10 min) for better flow in molding |

| Application | Films, sheets, pipe, wire insulation via extrusion | Complex shapes, containers, caps via injection molding |

| Mechanical Properties | Good tensile strength, flexibility for continuous profiles | High impact resistance, dimensional stability |

| Processing Temperature | Typically 180-240degC | Typically 190-260degC |

| Viscosity | Higher viscosity for stable extrusion flow | Lower viscosity to enable rapid mold filling |

Introduction to Polyethylene: An Overview

Polyethylene is a versatile polymer widely used in various manufacturing processes, with extrusion grade and injection molding grade being key distinctions. Extrusion grade polyethylene is formulated for continuous shaping methods such as pipe, sheet, and film production, offering excellent flow and melt strength. Injection molding grade polyethylene features enhanced melt flow properties suited for producing complex and precise parts with high dimensional stability.

Understanding Extrusion Grade Polyethylene

Extrusion grade polyethylene exhibits a consistent melt flow index (MFI) optimized for continuous processes like film blowing and pipe manufacturing, ensuring uniform material flow and superior mechanical properties. Its molecular weight distribution is tailored to enhance elongation and toughness during extrusion, providing excellent surface finish and dimensional stability. Understanding these characteristics allows manufacturers to select the appropriate grade for high-performance applications requiring durability and flexibility.

Characteristics of Injection Molding Grade Polyethylene

Injection molding grade polyethylene exhibits high melt flow index values, enabling precise and rapid filling of intricate molds during the injection molding process. This grade offers superior dimensional stability and excellent surface finish, making it ideal for producing complex, high-detail components. Its enhanced thermal properties and controlled molecular weight distribution ensure consistent mechanical strength and resistance to warping or shrinkage in finished parts.

Key Differences Between Extrusion and Injection Molding Grades

Extrusion grade polyethylene features higher melt flow index, allowing continuous shaping through dies, ideal for pipes and films, whereas injection molding grade has lower melt flow for better dimensional stability and surface finish in complex molds. Extrusion grade typically exhibits better impact resistance and flexibility, while injection molding grade offers enhanced tensile strength and rigidity critical for precise, detailed parts. Processing temperatures and additives vary to optimize performance in their respective manufacturing methods, influencing crystallinity and mechanical properties significantly.

Applications of Extrusion Grade Polyethylene

Extrusion grade polyethylene is primarily used in applications such as film production, pipes, and profiles due to its excellent flow properties and high melt strength. This grade is ideal for creating flexible packaging materials, agricultural films, and cable insulation where durability and consistent thickness are critical. Its ability to form uniform, continuous shapes makes it the preferred choice over injection molding grade polyethylene for large-scale, continuous manufacturing processes.

Common Uses for Injection Molding Grade Polyethylene

Injection molding grade polyethylene is widely used in manufacturing precise, complex shapes such as containers, caps, and automotive parts due to its excellent flow properties and dimensional stability. This grade is preferred for producing high-volume, intricate components like medical devices, toys, and household items, where detailed molding and surface finish are critical. Its ability to withstand repeated thermal cycles and provide strong, durable end products makes it ideal for applications requiring both toughness and aesthetic quality.

Processing Parameters: Extrusion vs Injection Molding

Extrusion grade polyethylene typically requires lower melt temperatures around 180-230degC and higher shear rates to ensure continuous flow through the die, whereas injection molding grade polyethylene demands precise temperature control between 200-260degC and optimized pressure profiles to fill complex molds effectively. Screw speed and back pressure differ significantly; extrusion relies on steady screw speed to maintain a constant melt viscosity, while injection molding uses variable injection speed and holding pressure to reduce shrinkage and warpage. Cooling rates also vary, with extrusion benefiting from gradual cooling for dimensional stability and injection molding utilizing rapid cooling cycles to accelerate part ejection and cycle time efficiency.

Performance and Mechanical Properties Comparison

Extrusion grade polyethylene typically offers superior melt flow rates and enhanced flexibility, making it ideal for continuous shaping processes, while injection molding grade exhibits higher tensile strength and improved impact resistance suited for complex, detailed parts. Mechanical properties such as elongation at break and hardness vary, with injection molding grades providing better dimensional stability and surface finish. Performance differences stem from variations in molecular weight distribution and additives used to tailor the polymer's flow behavior and structural integrity.

Selecting the Right Grade for Your Application

Choosing the appropriate polyethylene grade depends on the fabrication method and final product requirements. Extrusion grade polyethylene offers superior melt flow and is ideal for continuous shapes like films and pipes, while injection molding grade provides enhanced viscosity control for detailed and complex parts. Understanding the material's melt index and tensile strength ensures optimal performance and longevity in applications ranging from packaging to automotive components.

Future Trends in Polyethylene Grades and Manufacturing

Future trends in polyethylene grades emphasize enhanced extrusion and injection molding formulations with improved thermal stability and mechanical properties to meet growing demands in automotive and packaging industries. Advances in catalyst technology and copolymerization techniques enable tailored molecular weight distribution and branching, optimizing flow behavior and surface finish for both extrusion grade and injection molding grade resins. Sustainable manufacturing approaches, including bio-based polyethylene and recyclability enhancements, are increasingly integrated to reduce environmental impact while maintaining performance standards in diversified applications.

Extrusion Grade vs Injection Molding Grade Infographic

materialdif.com

materialdif.com