Metallocene polyethylene (PE) offers superior clarity, uniformity, and mechanical properties compared to Ziegler-Natta PE due to its single-site catalyst system that controls polymer structure at a molecular level. Ziegler-Natta PE typically features broader molecular weight distribution and less precise comonomer incorporation, resulting in varied material performance. Choosing metallocene PE delivers enhanced toughness, better processability, and consistent product quality for advanced applications.

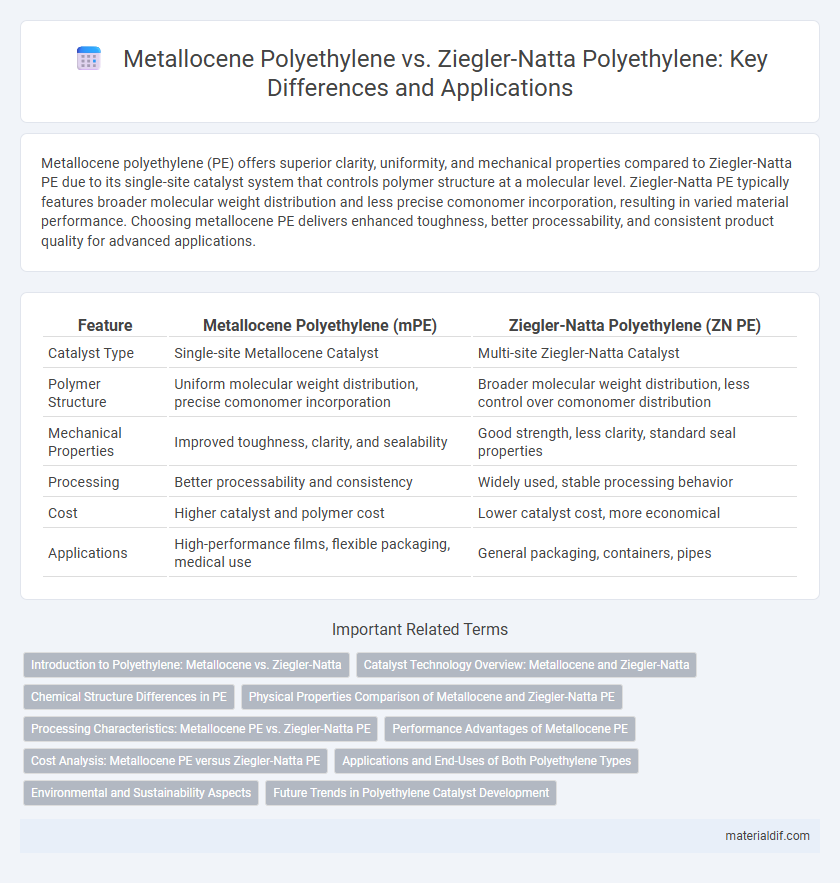

Table of Comparison

| Feature | Metallocene Polyethylene (mPE) | Ziegler-Natta Polyethylene (ZN PE) |

|---|---|---|

| Catalyst Type | Single-site Metallocene Catalyst | Multi-site Ziegler-Natta Catalyst |

| Polymer Structure | Uniform molecular weight distribution, precise comonomer incorporation | Broader molecular weight distribution, less control over comonomer distribution |

| Mechanical Properties | Improved toughness, clarity, and sealability | Good strength, less clarity, standard seal properties |

| Processing | Better processability and consistency | Widely used, stable processing behavior |

| Cost | Higher catalyst and polymer cost | Lower catalyst cost, more economical |

| Applications | High-performance films, flexible packaging, medical use | General packaging, containers, pipes |

Introduction to Polyethylene: Metallocene vs. Ziegler-Natta

Metallocene polyethylene (mPE) offers enhanced molecular uniformity and superior clarity compared to Ziegler-Natta polyethylene (ZNPE), which is characterized by a broader molecular weight distribution and cost-efficiency. Metallocene catalysts enable precise control over polymer architecture, resulting in improved mechanical properties and processability. Ziegler-Natta catalysts remain widely used for large-scale polyethylene production due to their established technology and versatility in polymer grades.

Catalyst Technology Overview: Metallocene and Ziegler-Natta

Metallocene polyethylene (PE) utilizes metallocene catalysts, offering precise molecular weight distribution and enhanced polymer architecture control compared to traditional Ziegler-Natta catalysts. Ziegler-Natta PE relies on titanium-based catalysts that produce polymers with broader molecular weight distribution and less control over stereoregularity. The advanced metallocene catalyst technology enables production of polyethylene with superior clarity, strength, and flexibility, optimizing performance for high-value packaging and film applications.

Chemical Structure Differences in PE

Metallocene polyethylene (mPE) features a uniform molecular structure with narrow molecular weight distribution, resulting from single-site catalysts that enable precise control over polymer chain architecture. In contrast, Ziegler-Natta polyethylene (ZNPE) exhibits a broader molecular weight distribution and less uniformity due to heterogeneous catalytic sites leading to varied chain branching and molecular arrangements. This structural difference influences properties such as clarity, strength, and processability, with mPE generally offering superior mechanical and optical performance compared to traditional ZNPE.

Physical Properties Comparison of Metallocene and Ziegler-Natta PE

Metallocene polyethylene (PE) exhibits superior molecular uniformity and narrower molecular weight distribution compared to Ziegler-Natta PE, resulting in enhanced mechanical properties such as increased tensile strength and improved clarity. The precise catalyst control in metallocene PE production allows for better density and crystallinity tuning, which contributes to higher impact resistance and flexibility relative to Ziegler-Natta PE. Additionally, metallocene PE demonstrates improved environmental stress crack resistance and more consistent thermal properties, making it suitable for advanced packaging and film applications.

Processing Characteristics: Metallocene PE vs. Ziegler-Natta PE

Metallocene polyethylene (PE) offers superior processing characteristics compared to Ziegler-Natta PE, including enhanced clarity, uniform molecular weight distribution, and improved stiffness. Its narrow molecular weight distribution enables precise control during extrusion and injection molding, resulting in optimized surface finish and better dimensional stability. In contrast, Ziegler-Natta PE typically exhibits broader molecular weight distribution, leading to less consistent processing and variations in mechanical properties.

Performance Advantages of Metallocene PE

Metallocene polyethylene (PE) offers superior clarity, uniform molecular weight distribution, and enhanced mechanical properties compared to Ziegler-Natta PE, resulting in improved toughness and flexibility. The precise catalyst control in metallocene PE production yields consistent polymer chains that enhance processing efficiency and product performance. These characteristics make metallocene PE ideal for high-performance applications such as films, medical devices, and flexible packaging.

Cost Analysis: Metallocene PE versus Ziegler-Natta PE

Metallocene polyethylene (PE) typically incurs higher production costs than Ziegler-Natta PE due to the expensive catalysts and complex polymerization processes involved. Despite the increased expense, Metallocene PE offers superior material properties such as enhanced clarity, toughness, and uniformity, which can justify the higher price in specialized applications. Ziegler-Natta PE remains more cost-effective for large-scale, general-purpose uses, benefiting from established technology and lower catalyst costs.

Applications and End-Uses of Both Polyethylene Types

Metallocene polyethylene (PE) is preferred for applications requiring superior clarity, flexibility, and uniformity, such as food packaging films, medical devices, and high-performance irrigation tubing due to its precise molecular structure and narrow molecular weight distribution. Ziegler-Natta PE, known for its cost-effectiveness and versatility, is widely used in consumer goods, pipes, blow-molded containers, and injection-molded products where mechanical strength and toughness are critical. Both types serve overlapping markets, but metallocene PE dominates sectors demanding high optical properties and regulatory compliance, while Ziegler-Natta PE remains dominant in large-scale, general-purpose polyethylene manufacturing.

Environmental and Sustainability Aspects

Metallocene polyethylene (PE) offers superior environmental benefits compared to Ziegler-Natta PE due to its enhanced polymer uniformity and narrower molecular weight distribution, leading to improved recyclability and reduced material waste. The precise catalyst control in metallocene PE production enables lower energy consumption and fewer emissions during manufacturing, supporting sustainability goals. Ziegler-Natta PE, while widely used, typically generates more by-products and has a broader polymer structure, which can hinder efficient recycling and contribute to higher environmental impact.

Future Trends in Polyethylene Catalyst Development

Metallocene polyethylene (PE) catalysts offer superior control over polymer architecture, resulting in enhanced material properties such as clarity, strength, and flexibility compared to traditional Ziegler-Natta PE catalysts. Future trends in polyethylene catalyst development focus on combining the precision of metallocene catalysts with the cost-effectiveness and scalability of Ziegler-Natta processes to create hybrid catalysts that optimize polymer performance and production efficiency. Advances in catalyst design aim to improve environmental sustainability by reducing energy consumption and enabling the use of bio-based monomers in PE production.

Metallocene PE vs Ziegler-Natta PE Infographic

materialdif.com

materialdif.com