Medical-grade polyethylene (PE) is specifically engineered for biocompatibility, sterility, and regulatory compliance, making it ideal for medical devices, implants, and pharmaceutical packaging. In contrast, general-purpose PE prioritizes cost-efficiency and versatility, used extensively in packaging, containers, and everyday consumer products. The enhanced purity and controlled manufacturing processes of medical-grade PE ensure safety and performance standards that general-purpose PE cannot guarantee.

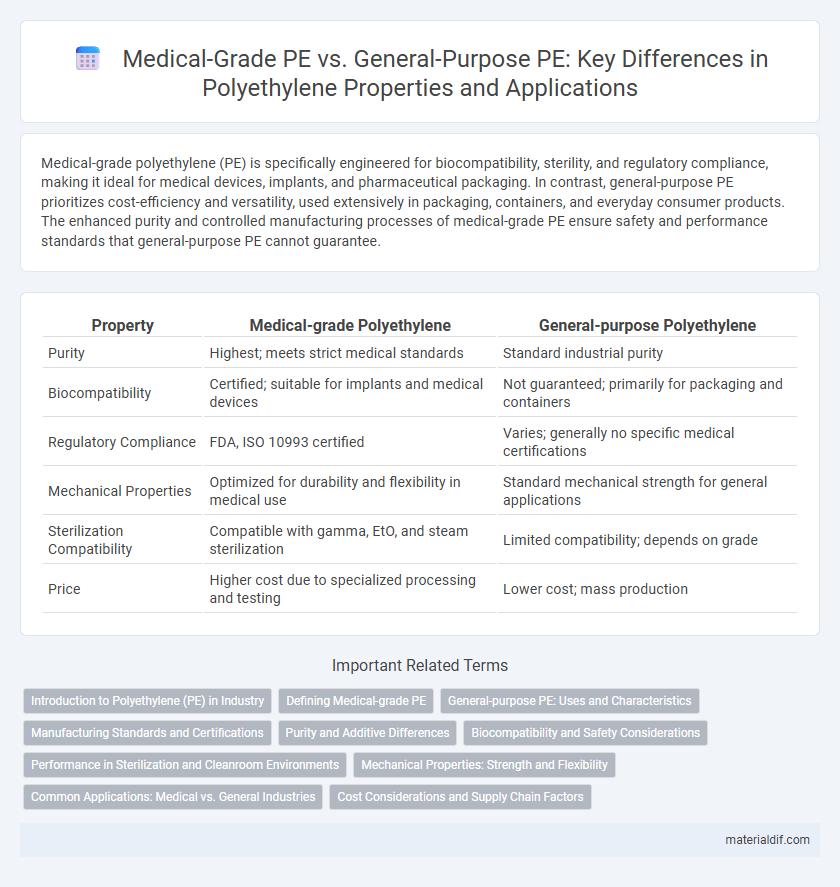

Table of Comparison

| Property | Medical-grade Polyethylene | General-purpose Polyethylene |

|---|---|---|

| Purity | Highest; meets strict medical standards | Standard industrial purity |

| Biocompatibility | Certified; suitable for implants and medical devices | Not guaranteed; primarily for packaging and containers |

| Regulatory Compliance | FDA, ISO 10993 certified | Varies; generally no specific medical certifications |

| Mechanical Properties | Optimized for durability and flexibility in medical use | Standard mechanical strength for general applications |

| Sterilization Compatibility | Compatible with gamma, EtO, and steam sterilization | Limited compatibility; depends on grade |

| Price | Higher cost due to specialized processing and testing | Lower cost; mass production |

Introduction to Polyethylene (PE) in Industry

Medical-grade polyethylene (PE) differs from general-purpose PE primarily in purity, biocompatibility, and regulatory compliance, making it suitable for critical applications like implants and surgical devices. General-purpose PE is widely used in packaging, containers, and everyday products due to its cost-effectiveness and versatile physical properties. Both types of PE offer excellent chemical resistance and durability, but medical-grade PE undergoes stringent quality control to meet industry standards such as FDA and ISO certifications.

Defining Medical-grade PE

Medical-grade polyethylene (PE) is specifically formulated to meet stringent biocompatibility and purity standards required for medical applications, ensuring it is free from harmful additives and contaminants. Unlike general-purpose PE, medical-grade variants undergo rigorous testing for cytotoxicity, sterilization compatibility, and chemical stability to guarantee safety within the human body. This specialized formulation ensures medical-grade PE is suitable for implants, drug delivery systems, and surgical devices, where regulatory compliance and patient safety are paramount.

General-purpose PE: Uses and Characteristics

General-purpose polyethylene (PE) is widely utilized in packaging, plastic bags, containers, and household goods due to its excellent chemical resistance, flexibility, and durability. Unlike medical-grade PE, it does not meet stringent purity or biocompatibility standards, making it unsuitable for sterile or implantable medical applications. Its versatility and cost-effectiveness make general-purpose PE ideal for everyday consumer products and industrial applications.

Manufacturing Standards and Certifications

Medical-grade polyethylene (PE) complies with stringent manufacturing standards such as ISO 13485 and FDA 21 CFR Part 820, ensuring biocompatibility and purity for safe use in medical applications. General-purpose PE typically adheres to less rigorous standards like ASTM D1248, focusing more on mechanical properties and chemical resistance suitable for industrial and consumer goods. Certifications for medical-grade PE often include USP Class VI and ISO 10993 biocompatibility testing, which are not standard requirements for general-purpose PE.

Purity and Additive Differences

Medical-grade polyethylene (PE) exhibits significantly higher purity levels compared to general-purpose PE, achieved through rigorous purification processes that eliminate contaminants and impurities. The additive formulations in medical-grade PE are carefully selected to meet biocompatibility standards, avoiding potentially harmful stabilizers, plasticizers, and fillers commonly found in general-purpose PE. These distinctions ensure medical-grade PE performs safely in implants and devices, maintaining sterility and reducing adverse biological reactions.

Biocompatibility and Safety Considerations

Medical-grade polyethylene (PE) exhibits superior biocompatibility compared to general-purpose PE, making it ideal for implants and surgical devices due to its minimal cytotoxicity and resistance to sterilization processes. Its enhanced purity and controlled manufacturing standards ensure reduced leachables and extractables, significantly lowering the risk of adverse tissue reactions. General-purpose PE lacks these stringent safety considerations, limiting its application in medical environments where biocompatibility is critical.

Performance in Sterilization and Cleanroom Environments

Medical-grade polyethylene (PE) exhibits superior performance in sterilization and cleanroom environments compared to general-purpose PE due to its enhanced purity, controlled molecular weight distribution, and resistance to gamma and ethylene oxide sterilization methods. This type of PE maintains structural integrity and prevents contamination under stringent FDA and ISO 13485 standards, making it ideal for medical devices and pharmaceutical packaging. In contrast, general-purpose PE lacks the stringent quality controls and may degrade or leach contaminants during sterilization, compromising product safety and efficacy.

Mechanical Properties: Strength and Flexibility

Medical-grade polyethylene (PE) exhibits superior mechanical properties compared to general-purpose PE, including enhanced tensile strength and greater flexibility, which are critical for biomedical applications such as implants and prosthetics. Its molecular structure and manufacturing processes result in a more uniform polymer matrix, reducing the risk of mechanical failure under stress and fatigue. In contrast, general-purpose PE offers lower strength and flexibility, making it less suitable for demanding medical environments where durability and biocompatibility are essential.

Common Applications: Medical vs. General Industries

Medical-grade polyethylene (PE) is primarily used in applications requiring biocompatibility and sterility, such as surgical instruments, implants, and drug delivery systems, where purity and non-toxicity are critical. General-purpose PE finds widespread applications in packaging, containers, automotive parts, and household goods due to its versatility, durability, and cost-effectiveness. The stringent regulatory standards for medical-grade PE ensure its suitability for sensitive healthcare uses, contrasting with the broader, less regulated general industrial applications of standard polyethylene.

Cost Considerations and Supply Chain Factors

Medical-grade polyethylene (PE) typically incurs higher costs due to stricter regulatory compliance, enhanced purity requirements, and specialized manufacturing processes essential for biocompatibility. Supply chain factors for medical-grade PE involve limited suppliers, longer lead times, and stringent quality controls, increasing overall procurement complexity compared to general-purpose PE. General-purpose PE benefits from broader availability and lower material costs, making it more economical for high-volume applications without stringent medical standards.

Medical-grade PE vs General-purpose PE Infographic

materialdif.com

materialdif.com