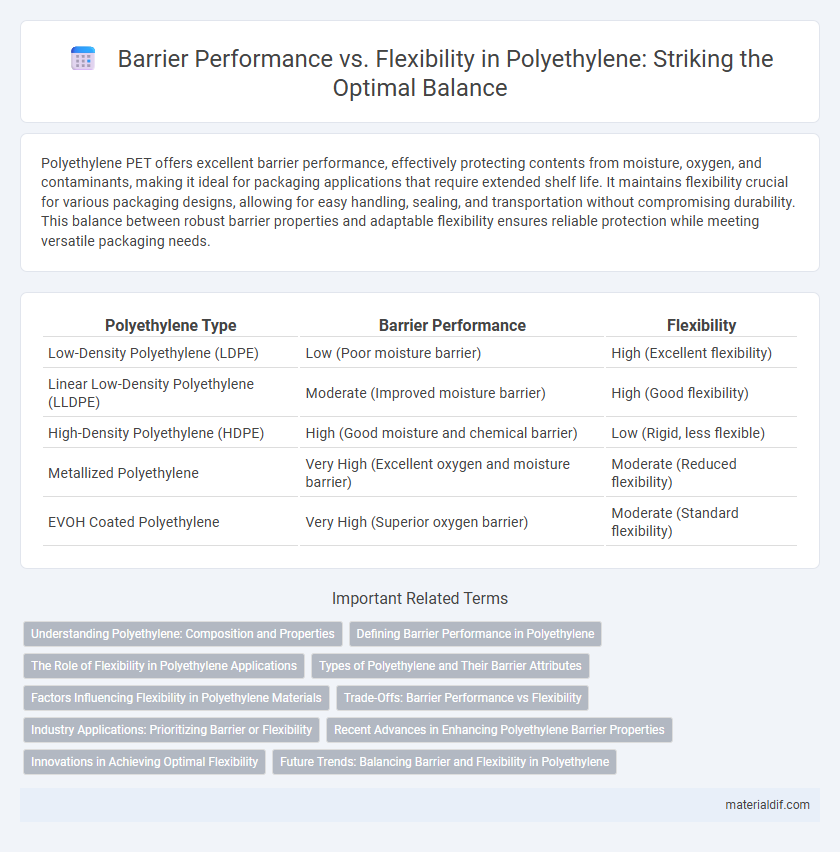

Polyethylene PET offers excellent barrier performance, effectively protecting contents from moisture, oxygen, and contaminants, making it ideal for packaging applications that require extended shelf life. It maintains flexibility crucial for various packaging designs, allowing for easy handling, sealing, and transportation without compromising durability. This balance between robust barrier properties and adaptable flexibility ensures reliable protection while meeting versatile packaging needs.

Table of Comparison

| Polyethylene Type | Barrier Performance | Flexibility |

|---|---|---|

| Low-Density Polyethylene (LDPE) | Low (Poor moisture barrier) | High (Excellent flexibility) |

| Linear Low-Density Polyethylene (LLDPE) | Moderate (Improved moisture barrier) | High (Good flexibility) |

| High-Density Polyethylene (HDPE) | High (Good moisture and chemical barrier) | Low (Rigid, less flexible) |

| Metallized Polyethylene | Very High (Excellent oxygen and moisture barrier) | Moderate (Reduced flexibility) |

| EVOH Coated Polyethylene | Very High (Superior oxygen barrier) | Moderate (Standard flexibility) |

Understanding Polyethylene: Composition and Properties

Polyethylene's barrier performance is influenced by its molecular density and crystallinity, with high-density polyethylene (HDPE) offering superior moisture resistance and chemical protection compared to low-density variants (LDPE) that provide greater flexibility. The polymer's linear structure in HDPE results in tighter molecular packing, enhancing barrier properties but reducing elasticity. Balancing polyethylene's composition enables tailored applications by optimizing flexibility and durability for packaging, films, and containers.

Defining Barrier Performance in Polyethylene

Barrier performance in polyethylene is defined by its ability to resist the permeation of gases, moisture, and chemicals, critical for preserving product integrity in packaging applications. The crystalline structure and molecular orientation significantly influence permeability rates, with higher crystallinity enhancing barrier properties but reducing flexibility. Optimizing polyethylene formulations balances barrier effectiveness with mechanical flexibility to meet specific industry requirements such as food packaging and medical devices.

The Role of Flexibility in Polyethylene Applications

Flexibility in polyethylene significantly enhances its barrier performance by allowing the material to conform closely to various shapes, reducing gaps that could compromise protection. This adaptability makes it ideal for applications such as flexible packaging, where maintaining a moisture and gas barrier is critical without sacrificing durability. Materials like low-density polyethylene (LDPE) exemplify this balance, combining flexibility with effective barrier properties for food preservation and industrial uses.

Types of Polyethylene and Their Barrier Attributes

Low-density polyethylene (LDPE) offers excellent flexibility due to its branched molecular structure but provides moderate barrier performance against moisture and gases. High-density polyethylene (HDPE) delivers superior barrier properties with its dense, linear polymer chains, enhancing resistance to chemical permeation while maintaining moderate flexibility. Linear low-density polyethylene (LLDPE) balances flexibility and barrier effectiveness, making it ideal for applications requiring both stretchability and protection from oxygen and moisture.

Factors Influencing Flexibility in Polyethylene Materials

Factors influencing flexibility in polyethylene materials include molecular weight, branching degree, and crystallinity level, which directly affect chain mobility and deformation capacity. Lower crystallinity and higher short-chain branching enhance flexibility by reducing intermolecular forces and increasing amorphous regions. Temperature and additives such as plasticizers also modulate flexibility by altering polymer chain dynamics and barrier performance.

Trade-Offs: Barrier Performance vs Flexibility

Polyethylene exhibits a notable trade-off between barrier performance and flexibility, where enhancements in barrier properties often result in decreased material pliability. High-density polyethylene (HDPE) offers superior gas and moisture resistance but sacrifices flexibility compared to low-density polyethylene (LDPE), which provides more elasticity but lower barrier protection. Optimizing polyethylene formulations and multilayer structures aims to balance these competing properties for applications like flexible packaging requiring both durability and environmental resistance.

Industry Applications: Prioritizing Barrier or Flexibility

In packaging industries, polyethylene's barrier performance is critical for preserving food freshness by preventing moisture and oxygen penetration, essential for pharmaceuticals and perishable goods. Conversely, applications in flexible packaging and agricultural films prioritize flexibility to allow easy handling and conformability without compromising durability. Manufacturers often tailor polyethylene formulations to balance barrier properties and flexibility based on specific industry needs, optimizing product performance for targeted applications.

Recent Advances in Enhancing Polyethylene Barrier Properties

Recent advances in enhancing polyethylene barrier properties focus on integrating nanocomposites and multilayer structures that significantly improve gas and moisture resistance without compromising flexibility. Incorporating clay nanoparticles and graphene oxide sheets creates tortuous paths for gas molecules, boosting barrier performance while maintaining elasticity. These innovations enable polyethylene films to meet the stringent demands of food packaging and medical applications, balancing durability with flexibility.

Innovations in Achieving Optimal Flexibility

Innovations in polyethylene have led to enhanced barrier performance while maintaining optimal flexibility through the development of advanced copolymers and multilayer structures. By incorporating nanocomposite fillers and optimizing molecular weight distribution, manufacturers improve gas and moisture resistance without compromising material elasticity. These technological advancements enable polyethylene films to meet rigorous packaging standards, balancing durability and pliability for diverse applications.

Future Trends: Balancing Barrier and Flexibility in Polyethylene

Emerging innovations in polyethylene focus on enhancing barrier performance without compromising flexibility, crucial for packaging and medical applications. Advanced copolymer structures and nanocomposites improve gas and moisture resistance while maintaining material pliability. Sustainable additives and bio-based modifiers are expected to drive future trends, optimizing the balance between barrier properties and mechanical flexibility.

Barrier performance vs Flexibility Infographic

materialdif.com

materialdif.com