Plasticizer-free polyethylene offers enhanced chemical resistance and durability compared to plasticized polyethylene, which incorporates additives to increase flexibility but can compromise mechanical strength over time. The absence of plasticizers in polyethylene ensures better environmental stability and reduces the risk of additive migration, making it ideal for applications requiring long-term performance and safety. Plasticized polyethylene, while more flexible, is prone to degradation and potential chemical leaching, limiting its use in sensitive or high-performance environments.

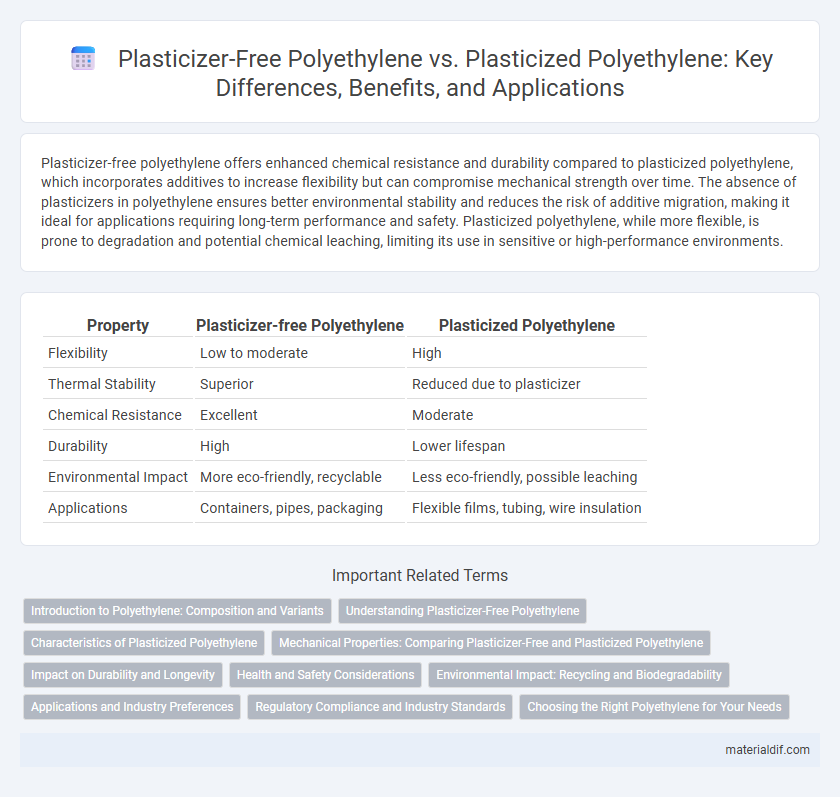

Table of Comparison

| Property | Plasticizer-free Polyethylene | Plasticized Polyethylene |

|---|---|---|

| Flexibility | Low to moderate | High |

| Thermal Stability | Superior | Reduced due to plasticizer |

| Chemical Resistance | Excellent | Moderate |

| Durability | High | Lower lifespan |

| Environmental Impact | More eco-friendly, recyclable | Less eco-friendly, possible leaching |

| Applications | Containers, pipes, packaging | Flexible films, tubing, wire insulation |

Introduction to Polyethylene: Composition and Variants

Polyethylene is a versatile polymer composed of repeating ethylene monomers, classified primarily into high-density polyethylene (HDPE) and low-density polyethylene (LDPE) based on branching and density variations. Plasticizer-free polyethylene maintains its inherent rigidity and chemical resistance, making it suitable for applications requiring durability and thermal stability. In contrast, plasticized polyethylene incorporates additives that enhance flexibility and softness, expanding its uses in flexible packaging, films, and pliable molded products.

Understanding Plasticizer-Free Polyethylene

Plasticizer-free polyethylene offers enhanced chemical stability and environmental resistance compared to plasticized polyethylene, which contains additives that improve flexibility but may leach over time. This type of polyethylene maintains its rigidity and strength without the risk of plasticizer migration, ensuring better durability in applications requiring long-term integrity. Understanding the molecular structure differences reveals that plasticizer-free polyethylene has a more consistent polymer matrix, leading to improved mechanical properties and reduced environmental impact.

Characteristics of Plasticized Polyethylene

Plasticized polyethylene exhibits enhanced flexibility and improved elongation properties compared to plasticizer-free polyethylene, due to the incorporation of additives that reduce intermolecular forces. This modification also results in increased softness and lower glass transition temperatures, making plasticized variants suitable for applications requiring pliability and impact resistance. However, the presence of plasticizers can affect thermal stability and may lead to migration or environmental concerns over time.

Mechanical Properties: Comparing Plasticizer-Free and Plasticized Polyethylene

Plasticizer-free polyethylene exhibits higher tensile strength and improved rigidity compared to plasticized polyethylene, which tends to have increased flexibility and elongation at break. The absence of plasticizers enhances the polymer's thermal stability and mechanical durability, making it suitable for load-bearing applications. In contrast, plasticized polyethylene offers better impact resistance and softness, favored in products requiring flexibility and cushioning.

Impact on Durability and Longevity

Plasticizer-free polyethylene exhibits enhanced durability and longevity due to its rigid molecular structure, which resists deformation and degradation over time. In contrast, plasticized polyethylene contains additives that increase flexibility but can lead to reduced mechanical strength and accelerated aging under environmental stressors. The absence of plasticizers in polyethylene formulations ensures sustained performance in applications requiring long-term stability and resistance to wear.

Health and Safety Considerations

Plasticizer-free polyethylene eliminates the risks associated with chemical migration and potential toxicity from additives commonly found in plasticized variants, enhancing consumer safety in food packaging and medical applications. Plasticized polyethylene, while offering increased flexibility, may release plasticizers such as phthalates that have been linked to endocrine disruption and other health concerns. Health and safety regulations increasingly favor plasticizer-free formulations to minimize exposure to harmful substances and ensure compliance with strict environmental and human toxicity standards.

Environmental Impact: Recycling and Biodegradability

Plasticizer-free polyethylene offers improved recyclability due to its pure polymer structure, which reduces contamination issues during the recycling process. In contrast, plasticized polyethylene contains additives that can hinder mechanical recycling and lead to the release of potentially harmful substances. Biodegradability remains low for both types, but plasticizer-free variants reduce environmental risks associated with additive leaching and microplastic formation.

Applications and Industry Preferences

Plasticizer-free polyethylene is favored in food packaging and medical industries due to its chemical purity and stability, ensuring no migration of additives that could contaminate products. Plasticized polyethylene offers enhanced flexibility and softness, making it ideal for applications like cable insulation, flexible tubing, and automotive parts where pliability is crucial. Industry preference typically leans towards plasticizer-free variants for high-purity requirements, while plasticized versions dominate sectors prioritizing material flexibility and durability.

Regulatory Compliance and Industry Standards

Plasticizer-free polyethylene complies more easily with stringent regulatory requirements such as FDA 21 CFR 177.1520, ensuring suitability for food contact and medical applications due to its inherently stable composition. In contrast, plasticized polyethylene often faces challenges meeting regulations like REACH and RoHS, as the added plasticizers can leach or degrade, necessitating rigorous testing and certification. Industry standards such as ASTM D638 and ISO 178 favor plasticizer-free variants for long-term durability and environmental safety, driving preference in sectors prioritizing compliance and sustainability.

Choosing the Right Polyethylene for Your Needs

Plasticizer-free polyethylene offers enhanced chemical resistance and stability, making it ideal for applications requiring durability and purity, such as food packaging and medical containers. Plasticized polyethylene, infused with additives to increase flexibility and softness, suits products like flexible films, cables, and toys where improved elasticity is essential. Selecting the appropriate polyethylene depends on balancing performance attributes like rigidity and flexibility with the end-use conditions, ensuring optimal functionality and lifespan.

Plasticizer-free Polyethylene vs Plasticized Polyethylene Infographic

materialdif.com

materialdif.com