Monolayer polyethylene film offers simplicity, cost-effectiveness, and ease of recycling, making it suitable for applications with minimal barrier requirements. Multilayer polyethylene film enhances performance with superior strength, moisture resistance, and oxygen barriers by combining different materials, ideal for preserving perishable goods. Choosing between monolayer and multilayer films depends on balancing budget constraints with desired protective properties for specific packaging needs.

Table of Comparison

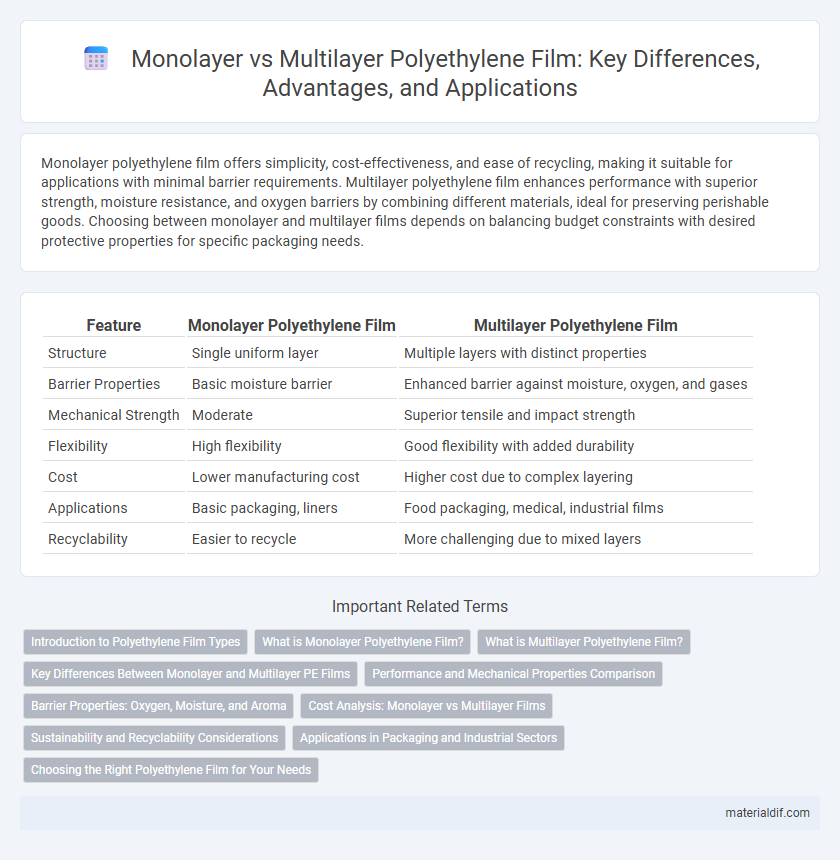

| Feature | Monolayer Polyethylene Film | Multilayer Polyethylene Film |

|---|---|---|

| Structure | Single uniform layer | Multiple layers with distinct properties |

| Barrier Properties | Basic moisture barrier | Enhanced barrier against moisture, oxygen, and gases |

| Mechanical Strength | Moderate | Superior tensile and impact strength |

| Flexibility | High flexibility | Good flexibility with added durability |

| Cost | Lower manufacturing cost | Higher cost due to complex layering |

| Applications | Basic packaging, liners | Food packaging, medical, industrial films |

| Recyclability | Easier to recycle | More challenging due to mixed layers |

Introduction to Polyethylene Film Types

Polyethylene film types primarily include monolayer and multilayer structures, each serving distinct purposes in packaging and industrial applications. Monolayer polyethylene film consists of a single uniform layer, offering simplicity, lower cost, and adequate barrier properties for basic uses. Multilayer polyethylene film combines two or more layers, enhancing mechanical strength, barrier performance, and flexibility for more demanding environments.

What is Monolayer Polyethylene Film?

Monolayer polyethylene film consists of a single uniform layer of polyethylene material, offering basic barrier properties and flexibility. It is commonly used for packaging applications requiring moisture resistance and lightweight protection. While simpler in structure, monolayer films often have limitations in durability and gas barrier performance compared to multilayer options.

What is Multilayer Polyethylene Film?

Multilayer polyethylene film consists of multiple layers of polyethylene or other polymers combined to enhance mechanical, barrier, and chemical properties compared to monolayer films. This structure improves resistance to moisture, oxygen, and punctures, making it ideal for packaging applications requiring extended shelf life and durability. The ability to customize each layer for specific functions allows multilayer polyethylene films to outperform single-layer films in performance and versatility.

Key Differences Between Monolayer and Multilayer PE Films

Monolayer polyethylene film consists of a single uniform layer, offering simplicity, cost-effectiveness, and ease of recycling, but it may lack advanced barrier properties. Multilayer polyethylene film combines multiple layers with different materials or additives, enhancing strength, moisture, oxygen resistance, and overall performance in packaging applications. The choice between monolayer and multilayer PE films depends on specific functional requirements, including durability, protection, and environmental impact.

Performance and Mechanical Properties Comparison

Monolayer polyethylene film offers uniform mechanical strength and excellent clarity but lacks the enhanced barrier properties of multilayer polyethylene film, which combines different resin layers to improve tensile strength, puncture resistance, and moisture barrier performance. Multilayer configurations enable tailored functionality by integrating high-density polyethylene (HDPE) with low-density polyethylene (LDPE) or linear low-density polyethylene (LLDPE), resulting in superior impact toughness and elongation at break. Performance in packaging applications favors multilayer films for demanding environments, while monolayer films are suitable for cost-effective, less critical uses.

Barrier Properties: Oxygen, Moisture, and Aroma

Monolayer polyethylene film offers moderate barrier properties against oxygen, moisture, and aroma, making it suitable for basic packaging needs. Multilayer polyethylene film incorporates specialized barrier layers such as EVOH or adhesive polymers that significantly enhance resistance to oxygen and moisture transmission, preserving product freshness and aroma integrity over extended periods. Advanced multilayer structures are preferred in food packaging industries where superior barrier performance is critical to maintaining shelf life and sensory quality.

Cost Analysis: Monolayer vs Multilayer Films

Monolayer polyethylene films typically incur lower production costs due to simpler manufacturing processes and reduced material usage compared to multilayer films. Multilayer polyethylene films, while more expensive to produce, offer enhanced barrier properties and mechanical strength that can reduce overall packaging costs by improving product shelf life and minimizing waste. Cost analysis must balance initial production expenses against long-term benefits such as durability, performance, and reduced material consumption.

Sustainability and Recyclability Considerations

Monolayer polyethylene film offers easier recyclability due to its uniform composition, enabling efficient recycling processes and minimal contamination risks. Multilayer polyethylene film, while providing enhanced barrier properties and durability, presents significant challenges for recycling because of its composite structure and diverse material layers. Sustainable packaging efforts increasingly favor monolayer films to improve circularity and reduce plastic waste, aligning with environmental regulations and corporate sustainability goals.

Applications in Packaging and Industrial Sectors

Monolayer polyethylene film offers cost-effective packaging solutions with excellent moisture barrier properties, widely used in food wrap and retail bags. Multilayer polyethylene film combines different material layers to enhance strength, oxygen barrier, and puncture resistance, making it ideal for industrial packaging and heavy-duty applications. In the packaging sector, multilayer films improve shelf life and product protection, while monolayer films are preferred for lightweight, flexible packaging needs.

Choosing the Right Polyethylene Film for Your Needs

Monolayer polyethylene film offers simplicity and cost-effectiveness, ideal for applications requiring basic moisture resistance and light barrier properties. Multilayer polyethylene film provides enhanced performance through combining different polymer layers, improving strength, flexibility, and superior barrier protection against gases, moisture, and contaminants. Selecting the right polyethylene film depends on specific application requirements such as durability, barrier efficiency, and budget constraints.

Monolayer Polyethylene Film vs Multilayer Polyethylene Film Infographic

materialdif.com

materialdif.com