High molecular weight polyethylene (HMWPE) exhibits superior tensile strength, abrasion resistance, and impact durability compared to low molecular weight polyethylene (LMWPE), making it ideal for demanding applications such as bulletproof vests and medical implants. In contrast, LMWPE offers greater flexibility and ease of processing, suitable for products like films and packaging. The distinct molecular weights directly influence the polymer chain length, affecting mechanical properties and end-use performance in polyethylene PET composites.

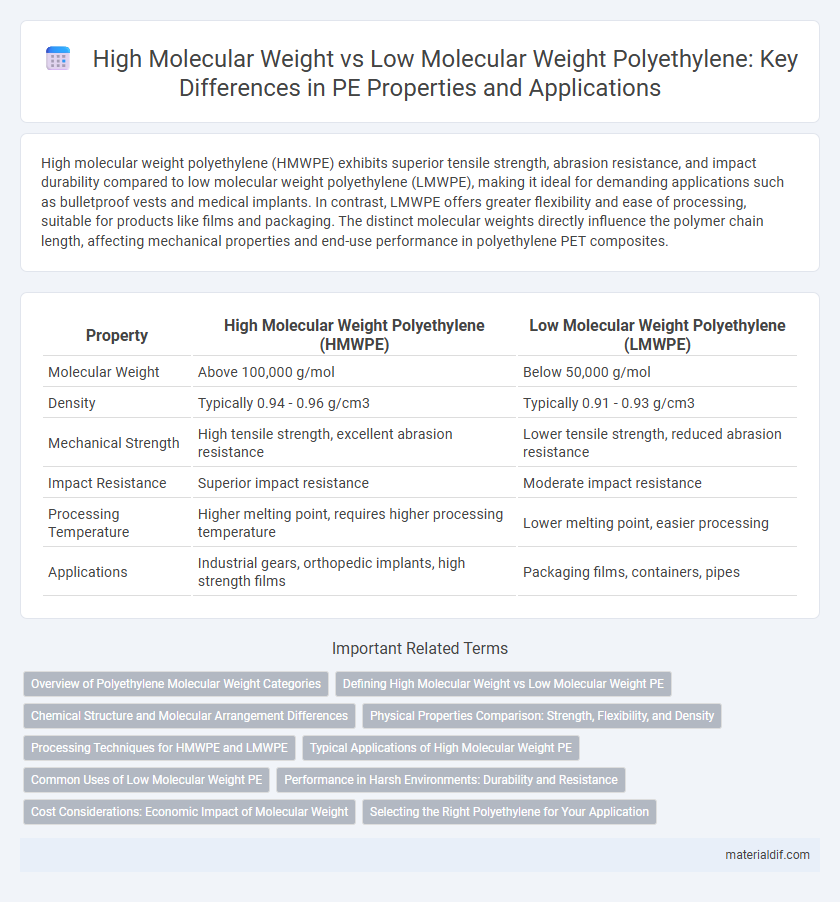

Table of Comparison

| Property | High Molecular Weight Polyethylene (HMWPE) | Low Molecular Weight Polyethylene (LMWPE) |

|---|---|---|

| Molecular Weight | Above 100,000 g/mol | Below 50,000 g/mol |

| Density | Typically 0.94 - 0.96 g/cm3 | Typically 0.91 - 0.93 g/cm3 |

| Mechanical Strength | High tensile strength, excellent abrasion resistance | Lower tensile strength, reduced abrasion resistance |

| Impact Resistance | Superior impact resistance | Moderate impact resistance |

| Processing Temperature | Higher melting point, requires higher processing temperature | Lower melting point, easier processing |

| Applications | Industrial gears, orthopedic implants, high strength films | Packaging films, containers, pipes |

Overview of Polyethylene Molecular Weight Categories

Polyethylene (PE) is classified into high molecular weight (HMWPE) and low molecular weight (LMWPE) categories based on polymer chain length, impacting strength and processing characteristics. HMWPE features longer chains, resulting in higher tensile strength, greater impact resistance, and improved wear properties, commonly used in high-performance applications like medical devices and industrial components. LMWPE, with shorter chains, exhibits lower density and enhanced processability, making it suitable for packaging films, containers, and flexible piping.

Defining High Molecular Weight vs Low Molecular Weight PE

High molecular weight polyethylene (HMWPE) typically has a molecular weight ranging from 100,000 to 500,000 g/mol, giving it superior tensile strength, abrasion resistance, and impact toughness compared to low molecular weight polyethylene (LMWPE), which usually falls below 100,000 g/mol. The higher molecular weight in HMWPE enhances chain entanglement and crystallinity, leading to improved mechanical properties and chemical resistance. In contrast, LMWPE offers better processability and flexibility but sacrifices durability and strength.

Chemical Structure and Molecular Arrangement Differences

High molecular weight polyethylene (HMWPE) consists of longer polymer chains leading to higher tensile strength and greater resistance to abrasion due to its dense molecular arrangement and stronger intermolecular forces. In contrast, low molecular weight polyethylene (LMWPE) has shorter polymer chains, resulting in a less ordered molecular structure with increased flexibility but lower mechanical strength. The chemical structure difference primarily lies in the chain length, which influences crystallinity and molecular packing, thereby affecting physical properties like density and melting point.

Physical Properties Comparison: Strength, Flexibility, and Density

High molecular weight polyethylene (HMWPE) exhibits superior tensile strength and impact resistance compared to low molecular weight polyethylene (LMWPE) due to its longer polymer chains and higher degree of crystallinity. LMWPE offers greater flexibility and easier processability but has lower density and reduced mechanical strength relative to HMWPE. The density of HMWPE typically ranges from 0.93 to 0.94 g/cm3, providing enhanced durability, while LMWPE density is marginally lower, contributing to its softer and more pliable nature.

Processing Techniques for HMWPE and LMWPE

High molecular weight polyethylene (HMWPE) requires specialized processing techniques such as gel spinning and compression molding to preserve its exceptional tensile strength and abrasion resistance, while low molecular weight polyethylene (LMWPE) is typically processed using conventional extrusion and injection molding methods due to its lower viscosity and ease of flow. HMWPE's high melt viscosity limits its processability in standard equipment, necessitating slow cooling rates and controlled shear conditions to maintain its molecular alignment and mechanical properties. In contrast, LMWPE's lower molecular weight facilitates rapid crystallization and faster production cycles, making it suitable for mass production of films, containers, and pipes.

Typical Applications of High Molecular Weight PE

High molecular weight polyethylene (HMWPE) is widely used in applications requiring exceptional strength and abrasion resistance, such as heavy-duty industrial liners, load-bearing components, and high-performance fibers. Its densely packed polymer chains provide superior impact resistance, making it ideal for ballistic protection and medical prosthetics. In contrast, low molecular weight polyethylene (LMWPE) finds common use in flexible films and packaging due to its lower tensile strength and higher processability.

Common Uses of Low Molecular Weight PE

Low molecular weight polyethylene (LMWPE) is widely used in applications requiring flexibility and ease of processing, such as film production for packaging, plastic bags, and shrink wraps. Its lower density and softer texture make it ideal for manufacturing squeeze bottles and liners for containers. In contrast to high molecular weight polyethylene (HMWPE), which is favored for its toughness and impact resistance in products like pipes and industrial parts, LMWPE excels in cost-effective, consumer-oriented plastic goods.

Performance in Harsh Environments: Durability and Resistance

High molecular weight polyethylene (HMWPE) exhibits superior durability and chemical resistance in harsh environments due to its longer polymer chains, resulting in enhanced impact strength and abrasion resistance. Low molecular weight polyethylene (LMWPE) tends to have lower mechanical strength and is more susceptible to environmental stress cracking and chemical degradation. Therefore, HMWPE is preferred for applications demanding long-term performance against aggressive chemicals, extreme temperatures, and mechanical wear.

Cost Considerations: Economic Impact of Molecular Weight

High molecular weight polyethylene (HMWPE) typically incurs higher production costs due to increased polymerization time and catalyst usage, impacting overall manufacturing expenses. Low molecular weight polyethylene (LMWPE) offers lower raw material and processing costs, making it more economical for applications requiring less mechanical strength. Cost efficiency in polymer selection hinges on balancing molecular weight with performance requirements and end-use specifications.

Selecting the Right Polyethylene for Your Application

High molecular weight polyethylene (HMWPE) offers superior impact resistance and tensile strength, making it ideal for heavy-duty applications such as industrial containers and piping systems. Low molecular weight polyethylene (LMWPE) provides greater flexibility and ease of processing, often preferred for film wrapping, packaging, and injection molding. Selecting the right polyethylene depends on specific performance requirements, balancing durability with manufacturability to optimize product functionality.

High molecular weight PE vs Low molecular weight PE Infographic

materialdif.com

materialdif.com