Polyethylene PET offers a unique balance between impact strength and tensile strength, making it ideal for applications requiring durability and flexibility. Its high impact strength allows for excellent resistance to sudden forces and shocks, while the tensile strength ensures the material can withstand substantial stretching and pulling without breaking. This combination enhances performance in packaging, automotive parts, and industrial components where both toughness and resilience are critical.

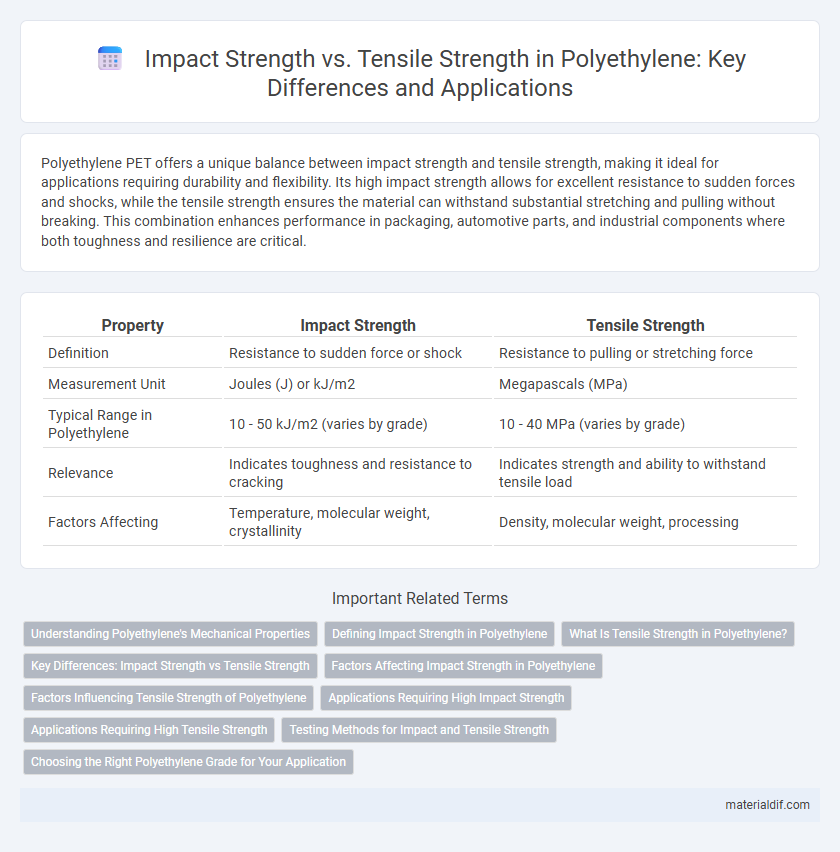

Table of Comparison

| Property | Impact Strength | Tensile Strength |

|---|---|---|

| Definition | Resistance to sudden force or shock | Resistance to pulling or stretching force |

| Measurement Unit | Joules (J) or kJ/m2 | Megapascals (MPa) |

| Typical Range in Polyethylene | 10 - 50 kJ/m2 (varies by grade) | 10 - 40 MPa (varies by grade) |

| Relevance | Indicates toughness and resistance to cracking | Indicates strength and ability to withstand tensile load |

| Factors Affecting | Temperature, molecular weight, crystallinity | Density, molecular weight, processing |

Understanding Polyethylene's Mechanical Properties

Polyethylene exhibits a unique balance between impact strength and tensile strength, critical for various industrial applications. Its impact strength allows it to absorb energy and resist sudden forces without fracturing, while the tensile strength defines its ability to withstand pulling or stretching forces. Understanding these mechanical properties helps engineers select the right polyethylene grade, such as high-density polyethylene (HDPE) for rigidity and tensile strength or low-density polyethylene (LDPE) for enhanced impact resistance and flexibility.

Defining Impact Strength in Polyethylene

Impact strength in polyethylene measures the material's ability to absorb and resist sudden forces or shocks without fracturing, highlighting its toughness under dynamic loads. It is a critical parameter for applications requiring durability against impact, such as packaging, automotive parts, and piping systems. This property differs from tensile strength, which quantifies the maximum stress polyethylene can withstand while being stretched before failure.

What Is Tensile Strength in Polyethylene?

Tensile strength in polyethylene refers to the maximum stress the material can withstand while being stretched or pulled before breaking. It is a critical measure of polyethylene's durability and resistance to deformation under tension, typically expressed in megapascals (MPa). In comparison, impact strength assesses polyethylene's ability to absorb sudden forces or shocks without fracturing, highlighting its toughness in dynamic conditions.

Key Differences: Impact Strength vs Tensile Strength

Impact strength measures a material's ability to resist sudden forces or shocks without breaking, while tensile strength quantifies the maximum stress polyethylene can endure when stretched or pulled before failure. Unlike tensile strength, which is a static property indicating load-bearing capacity under gradual tension, impact strength reflects dynamic resistance to rapid, high-energy impacts. Understanding these differences is crucial for selecting polyethylene grades tailored for applications requiring either durability under constant loads or resilience against abrupt impacts.

Factors Affecting Impact Strength in Polyethylene

Impact strength in polyethylene is influenced by molecular weight, crystallinity, and temperature, with higher molecular weight and lower crystallinity generally enhancing toughness. The amorphous regions in polyethylene absorb impact energy more effectively, while increased crystallinity tends to increase tensile strength but reduce impact resistance. Environmental factors such as low temperatures and the presence of stress concentrators significantly diminish the impact strength of polyethylene without substantially altering its tensile strength.

Factors Influencing Tensile Strength of Polyethylene

Tensile strength of polyethylene is primarily influenced by its molecular weight, degree of crystallinity, and branching structure. Higher molecular weight and increased crystallinity enhance intermolecular forces, resulting in improved tensile strength, while extensive branching reduces chain packing efficiency, lowering strength. Processing conditions such as cooling rate and orientation during extrusion also play critical roles in determining the final tensile properties of polyethylene materials.

Applications Requiring High Impact Strength

Polyethylene's high impact strength makes it ideal for applications such as protective packaging, automotive components, and sports equipment, where materials must absorb shocks without fracturing. While its tensile strength varies across types--HDPE offers higher tensile strength suited for structural uses--LLDPE excels in impact resistance, providing excellent durability under sudden force. Selecting polyethylene grades with superior impact strength ensures enhanced performance and longevity in demanding environments requiring toughness and flexibility.

Applications Requiring High Tensile Strength

Polyethylene exhibits varying mechanical properties, with high-density polyethylene (HDPE) offering superior tensile strength compared to low-density polyethylene (LDPE), making it ideal for applications requiring durability and resistance to mechanical stress. HDPE's tensile strength ranges from 20 to 37 MPa, enabling its use in containers, piping, and automotive parts where structural integrity is critical. While HDPE has moderate impact strength, its balance of high tensile strength and chemical resistance suits demanding industrial and packaging applications.

Testing Methods for Impact and Tensile Strength

Impact strength of polyethylene is typically evaluated using Charpy or Izod impact tests, which measure the energy absorbed during fracture under sudden loading conditions, providing insights into the material's resistance to shock. Tensile strength testing involves uniaxial tension using a universal testing machine, determining the maximum stress polyethylene can withstand before failure, essential for assessing its load-bearing capacity. Standardized testing methods such as ASTM D256 for impact and ASTM D638 for tensile strength ensure consistent, reliable characterization of polyethylene's mechanical properties.

Choosing the Right Polyethylene Grade for Your Application

Impact strength and tensile strength are critical parameters when selecting the right polyethylene grade for specific applications. High-density polyethylene (HDPE) offers superior tensile strength, making it ideal for load-bearing uses, while low-density polyethylene (LDPE) provides excellent impact resistance suitable for flexible packaging and protective films. Balancing these mechanical properties ensures optimal performance, durability, and cost-efficiency in product design.

Impact strength vs Tensile strength Infographic

materialdif.com

materialdif.com