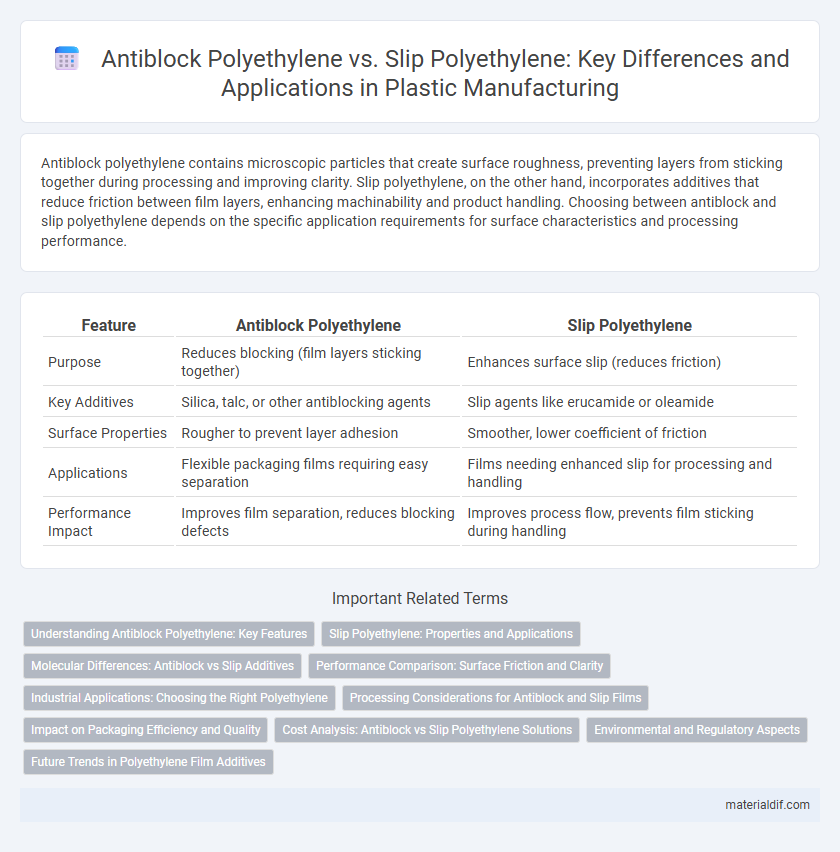

Antiblock polyethylene contains microscopic particles that create surface roughness, preventing layers from sticking together during processing and improving clarity. Slip polyethylene, on the other hand, incorporates additives that reduce friction between film layers, enhancing machinability and product handling. Choosing between antiblock and slip polyethylene depends on the specific application requirements for surface characteristics and processing performance.

Table of Comparison

| Feature | Antiblock Polyethylene | Slip Polyethylene |

|---|---|---|

| Purpose | Reduces blocking (film layers sticking together) | Enhances surface slip (reduces friction) |

| Key Additives | Silica, talc, or other antiblocking agents | Slip agents like erucamide or oleamide |

| Surface Properties | Rougher to prevent layer adhesion | Smoother, lower coefficient of friction |

| Applications | Flexible packaging films requiring easy separation | Films needing enhanced slip for processing and handling |

| Performance Impact | Improves film separation, reduces blocking defects | Improves process flow, prevents film sticking during handling |

Understanding Antiblock Polyethylene: Key Features

Antiblock polyethylene incorporates fine particles such as silica or talc to enhance surface friction, preventing film layers from sticking together during processing and handling. This modification improves clarity and printability while maintaining the material's inherent strength and flexibility. Understanding these key features is essential for selecting antiblock polyethylene in packaging applications where slip control is critical.

Slip Polyethylene: Properties and Applications

Slip Polyethylene is engineered with slip agents that reduce the coefficient of friction on the film surface, enhancing processability and handling in packaging applications. Its key properties include improved surface smoothness, resistance to blocking, and excellent clarity, making it ideal for flexible packaging, shrink films, and laminations. Common uses of Slip Polyethylene involve food packaging, industrial wrapping, and agricultural films, where easy unwind, reduced sticking, and high durability are critical performance factors.

Molecular Differences: Antiblock vs Slip Additives

Antiblock polyethylene contains additives such as silica or clay, which create microscopic surface roughness to prevent film layers from sticking together, enhancing material separation during processing. Slip polyethylene incorporates erucamide or oleamide additives that migrate to the surface, reducing friction and improving the slip properties of the polymer film. The molecular distinction lies in antiblock additives being particulate fillers that increase surface texture, whereas slip additives are fatty acid amides that act as lubricants at the molecular level.

Performance Comparison: Surface Friction and Clarity

Antiblock polyethylene features surface additives that increase friction, preventing film blocking while maintaining high optical clarity. Slip polyethylene contains additives that reduce surface friction, enhancing slip properties but potentially decreasing haze and overall transparency. Performance comparison reveals antiblock films are ideal for clarity-sensitive applications requiring non-sticking surfaces, whereas slip films excel where easy film handling and processing are prioritized despite minor clarity compromise.

Industrial Applications: Choosing the Right Polyethylene

Antiblock polyethylene enhances clarity and printability by preventing film layers from sticking, making it ideal for packaging applications that require transparency and high-quality graphics. Slip polyethylene incorporates slip agents to reduce surface friction, improving processing speed and handling in automated packaging lines, especially in flexible films and bags. Selecting the right polyethylene depends on the balance between surface properties and functional requirements in industries such as food packaging, pharmaceuticals, and consumer goods.

Processing Considerations for Antiblock and Slip Films

Antiblock polyethylene films require precise control of processing parameters like melt temperature and cooling rate to maintain uniform dispersion of antiblocking agents, preventing surface defects and preserving clarity. Slip polyethylene films demand careful adjustment of die gap and cooling conditions to achieve optimal surface lubrication, reducing friction and improving machinability in converting processes. Both antiblock and slip films necessitate tailored processing conditions to balance film performance and production efficiency in flexible packaging applications.

Impact on Packaging Efficiency and Quality

Antiblock polyethylene incorporates microscopic particles to reduce film clinging, enhancing packaging efficiency by preventing sheet sticking and facilitating smoother machine operation. Slip polyethylene contains lubricants that decrease surface friction, improving film handling speed and reducing jams, which elevates packaging throughput and product quality. The combined use of antiblock and slip additives optimizes film performance by balancing clarity, printability, and mechanical strength, crucial for high-quality packaging applications.

Cost Analysis: Antiblock vs Slip Polyethylene Solutions

Antiblock polyethylene typically incurs higher production costs due to the incorporation of specialized additives that enhance surface friction and prevent film blocking, resulting in increased raw material expenses. Slip polyethylene offers a cost-effective solution by reducing surface friction through slip agents, leading to lower material costs and improved processing efficiency. Evaluating total cost of ownership, slip polyethylene often provides better value in high-speed packaging applications, while antiblock polyethylene is preferred for films requiring superior clarity and anti-blocking performance despite higher costs.

Environmental and Regulatory Aspects

Antiblock polyethylene incorporates additives that enhance transparency by preventing film layers from sticking, though these additives may introduce environmental concerns related to chemical migration and disposal regulations. Slip polyethylene contains lubricants that reduce friction and improve processing efficiency but can pose challenges in recyclability due to residue affecting polymer purity. Regulatory agencies increasingly scrutinize additive compositions in both antiblock and slip polyethylenes to ensure compliance with safety, migration limits, and environmental impact standards in packaging applications.

Future Trends in Polyethylene Film Additives

Future trends in polyethylene film additives emphasize the development of multifunctional antiblock and slip agents that enhance film clarity, processability, and mechanical properties. Innovations target biodegradable and bio-based additives to improve sustainability while maintaining performance in antiblock polyethylene and slip polyethylene films. Advances in nanotechnology and surface treatment further optimize additive efficiency, extending service life and reducing environmental impact in packaging applications.

Antiblock Polyethylene vs Slip Polyethylene Infographic

materialdif.com

materialdif.com