Linear polyethylene (PE) features a straight-chain molecular structure that provides higher density, increased tensile strength, and improved chemical resistance, making it ideal for durable packaging and industrial applications. Branched polyethylene, with its irregular branching, results in lower density and greater flexibility, commonly used in films and plastic bags where softness and clarity are essential. The choice between linear and branched PE depends on the desired balance between mechanical strength and flexibility in products like polyethylene terephthalate (PET) containers.

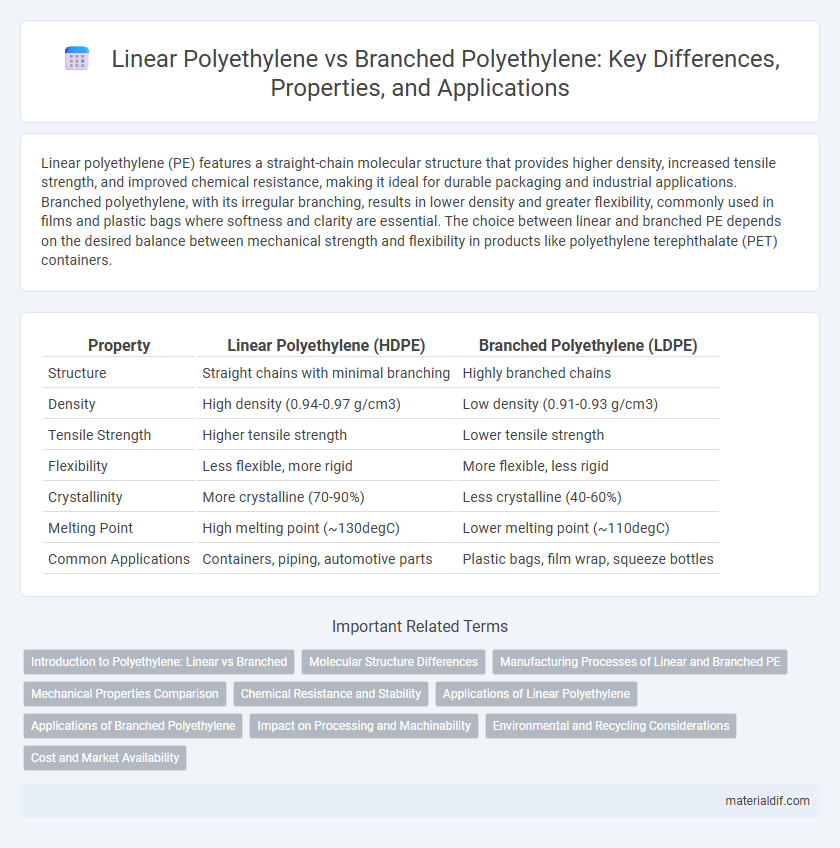

Table of Comparison

| Property | Linear Polyethylene (HDPE) | Branched Polyethylene (LDPE) |

|---|---|---|

| Structure | Straight chains with minimal branching | Highly branched chains |

| Density | High density (0.94-0.97 g/cm3) | Low density (0.91-0.93 g/cm3) |

| Tensile Strength | Higher tensile strength | Lower tensile strength |

| Flexibility | Less flexible, more rigid | More flexible, less rigid |

| Crystallinity | More crystalline (70-90%) | Less crystalline (40-60%) |

| Melting Point | High melting point (~130degC) | Lower melting point (~110degC) |

| Common Applications | Containers, piping, automotive parts | Plastic bags, film wrap, squeeze bottles |

Introduction to Polyethylene: Linear vs Branched

Linear polyethylene (PE) features a straight carbon chain with minimal branching, resulting in higher density, tensile strength, and crystallinity compared to branched polyethylene. Branched PE contains side chains that disrupt crystal formation, leading to lower density, increased flexibility, and improved impact resistance. These structural differences determine their applications, with linear PE commonly used in high-strength packaging and branched PE preferred for films and containers requiring flexibility.

Molecular Structure Differences

Linear polyethylene (PE) consists of long, straight polymer chains with minimal branching, resulting in a tightly packed molecular structure that enhances crystallinity and density. Branched polyethylene contains side chains of varying length attached to the main polymer backbone, disrupting molecular packing and reducing crystallinity and density. These structural differences directly influence the mechanical properties and melting temperatures of the polymers.

Manufacturing Processes of Linear and Branched PE

Linear polyethylene (PE) is primarily produced through high-pressure free-radical polymerization or by using Ziegler-Natta and metallocene catalysts in low-pressure processes, resulting in a polymer chain with minimal branching and higher density. Branched polyethylene typically involves high-pressure polymerization methods, like radical polymerization, which introduce long and short chain branches, reducing crystallinity and density. The choice of catalyst and polymerization conditions directly influences the molecular architecture, affecting the mechanical properties and applications of the resulting polyethylene.

Mechanical Properties Comparison

Linear polyethylene (PE) exhibits higher tensile strength and stiffness compared to branched PE due to its closely packed molecular chains and crystallinity. Branched PE, characterized by side chains that disrupt chain packing, offers greater flexibility and impact resistance but lower mechanical robustness. The reduced crystallinity in branched PE results in decreased density and mechanical strength, making linear PE preferable for load-bearing applications.

Chemical Resistance and Stability

Linear polyethylene (Linear PE) exhibits higher chemical resistance and enhanced stability compared to branched polyethylene due to its tightly packed molecular structure and reduced chain branching. The minimal branching in Linear PE results in increased crystallinity, which improves its barrier properties against solvents, acids, and alkalis. Branched polyethylene, with its irregular molecular configuration, tends to have lower chemical resistance and thermal stability, making it less suitable for applications requiring robust chemical durability.

Applications of Linear Polyethylene

Linear polyethylene (LPE) exhibits high density and tensile strength due to its minimal branching, making it ideal for applications such as packaging films, containers, and pipes that require durability and chemical resistance. Its uniform molecular structure enables excellent barrier properties, essential in food packaging and industrial liners. LPE is also widely used in automotive parts and wire insulation where rigidity and impact resistance are critical.

Applications of Branched Polyethylene

Branched polyethylene (PE), characterized by its numerous side chains, is widely used in applications requiring flexibility and toughness, such as plastic bags, squeeze bottles, and film wraps. Its branched structure lowers density and crystallinity, enhancing impact resistance and clarity, making it ideal for packaging materials. This form of PE is also preferred in manufacturing containers and toys due to its durability and ease of processing.

Impact on Processing and Machinability

Linear polyethylene (PE) exhibits higher crystallinity and density, resulting in improved tensile strength and better machinability due to its uniform molecular structure. Branched PE has lower crystallinity, causing increased flexibility but reduced mechanical strength, which can complicate processing and lead to challenges in maintaining dimensional stability during machining. The choice between linear and branched PE significantly influences melt flow behavior, cooling rates, and the precision of finished components in industrial applications.

Environmental and Recycling Considerations

Linear polyethylene (PE) exhibits higher density and crystallinity, resulting in enhanced mechanical properties and greater recyclability compared to branched PE. Branched polyethylene contains side chains that reduce density and crystallinity, making it more flexible but complicating recycling processes due to lower material uniformity. Environmentally, linear PE's improved recyclability contributes to reduced plastic waste and better circular economy outcomes, while branched PE often requires more energy-intensive recycling methods.

Cost and Market Availability

Linear polyethylene (PE) generally commands higher production costs due to its more complex catalyst systems, resulting in greater tensile strength and durability favored in high-performance applications. Branched PE, including low-density polyethylene (LDPE), boasts lower manufacturing costs and wider market availability, making it a cost-effective choice for packaging and film products. Market demand favors branched PE for flexible uses, while linear PE occupies niche segments requiring enhanced mechanical properties despite its higher price point.

Linear PE vs Branched PE Infographic

materialdif.com

materialdif.com