UV stabilized polyethylene offers enhanced durability and resistance to degradation when exposed to sunlight, making it ideal for outdoor applications. Non-stabilized polyethylene lacks this protection, leading to premature aging, brittleness, and reduced lifespan under UV exposure. Choosing UV stabilized polyethylene ensures better performance and longevity in environments with high sunlight exposure.

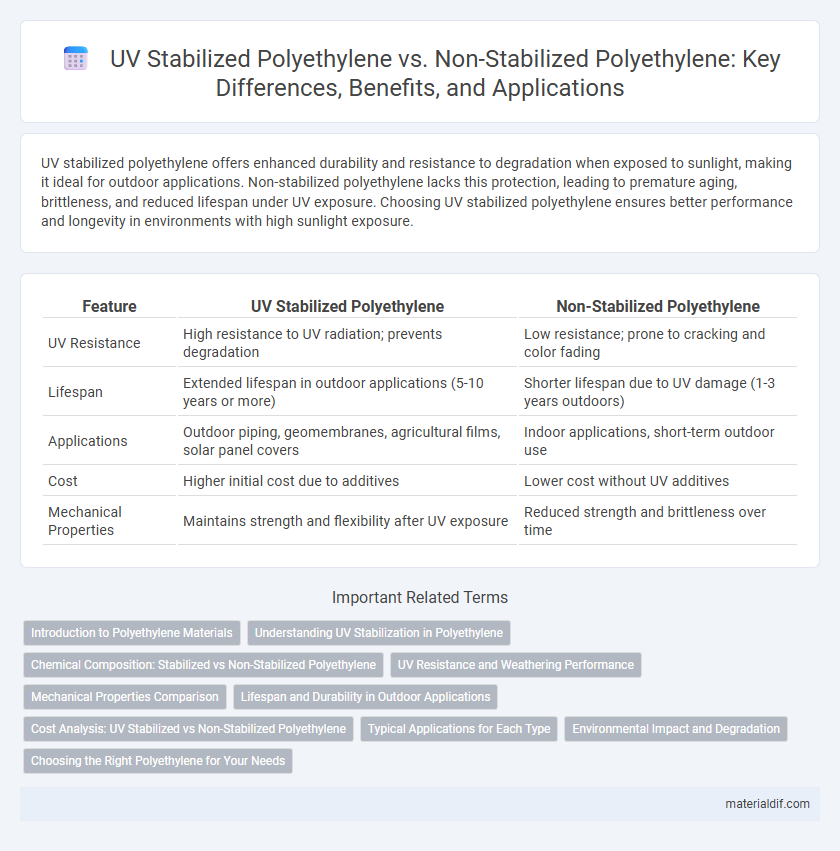

Table of Comparison

| Feature | UV Stabilized Polyethylene | Non-Stabilized Polyethylene |

|---|---|---|

| UV Resistance | High resistance to UV radiation; prevents degradation | Low resistance; prone to cracking and color fading |

| Lifespan | Extended lifespan in outdoor applications (5-10 years or more) | Shorter lifespan due to UV damage (1-3 years outdoors) |

| Applications | Outdoor piping, geomembranes, agricultural films, solar panel covers | Indoor applications, short-term outdoor use |

| Cost | Higher initial cost due to additives | Lower cost without UV additives |

| Mechanical Properties | Maintains strength and flexibility after UV exposure | Reduced strength and brittleness over time |

Introduction to Polyethylene Materials

UV stabilized polyethylene contains additives that protect the polymer chains from degradation caused by ultraviolet radiation, significantly enhancing its durability and lifespan in outdoor applications. Non-stabilized polyethylene lacks these UV inhibitors, making it more prone to brittleness, discoloration, and mechanical failure when exposed to prolonged sunlight. This distinction is critical in selecting polyethylene materials for products such as pipes, packaging, and geomembranes used in environments with high UV exposure.

Understanding UV Stabilization in Polyethylene

UV stabilized polyethylene contains additives such as UV absorbers and hindered amine light stabilizers (HALS) that protect the polymer chains from degradation caused by ultraviolet radiation exposure. Non-stabilized polyethylene lacks these protective compounds, resulting in accelerated oxidation, embrittlement, and discoloration when exposed to sunlight over time. Understanding UV stabilization is crucial for applications like outdoor piping, agricultural films, and packaging, where prolonged UV exposure compromises mechanical properties and lifespan.

Chemical Composition: Stabilized vs Non-Stabilized Polyethylene

UV stabilized polyethylene contains added chemical additives such as hindered amine light stabilizers (HALS) and UV absorbers that protect the polymer chains from photodegradation caused by ultraviolet radiation. Non-stabilized polyethylene lacks these protective additives, making it more susceptible to chain scission, discoloration, and loss of mechanical properties when exposed to prolonged UV light. The chemical composition of stabilized polyethylene ensures enhanced durability and longevity in outdoor applications compared to non-stabilized variants.

UV Resistance and Weathering Performance

UV stabilized polyethylene contains additives like carbon black or hindered amine light stabilizers (HALS) that significantly enhance its UV resistance compared to non-stabilized polyethylene. This stabilization prevents polymer chain degradation, extending the material's lifespan in outdoor applications exposed to sunlight and harsh weather conditions. Non-stabilized polyethylene degrades rapidly under UV exposure, leading to surface cracking, loss of mechanical properties, and reduced weathering performance.

Mechanical Properties Comparison

UV stabilized polyethylene exhibits enhanced mechanical properties compared to non-stabilized polyethylene, including greater tensile strength and improved elongation at break due to reduced degradation from ultraviolet light exposure. The incorporation of UV stabilizers effectively prevents polymer chain scission, maintaining the material's impact resistance and flexibility over extended outdoor use. Non-stabilized polyethylene tends to show significant decreases in mechanical performance such as embrittlement and surface cracking after prolonged UV exposure.

Lifespan and Durability in Outdoor Applications

UV stabilized polyethylene significantly outperforms non-stabilized polyethylene in outdoor applications by resisting degradation from ultraviolet radiation, thereby extending its lifespan by up to 3 to 5 times. The incorporation of UV stabilizers prevents molecular breakdown, maintaining mechanical integrity and flexibility under prolonged sun exposure. Non-stabilized polyethylene typically experiences brittleness, discoloration, and reduced durability within months, limiting its practical use in outdoor environments.

Cost Analysis: UV Stabilized vs Non-Stabilized Polyethylene

UV stabilized polyethylene incorporates additives that protect against degradation from ultraviolet radiation, resulting in higher initial material costs compared to non-stabilized polyethylene. Although the upfront expense of UV stabilized polyethylene is greater, it offers extended product lifespan and reduced maintenance or replacement frequency, which can lead to lower total lifecycle costs in outdoor applications. Non-stabilized polyethylene may be more cost-effective for short-term or indoor use but often incurs higher expenses over time due to UV-induced brittleness and material failure.

Typical Applications for Each Type

UV stabilized polyethylene is commonly used in outdoor applications such as agricultural films, outdoor furniture, and piping systems where exposure to sunlight can cause degradation. Non-stabilized polyethylene is typically employed in indoor applications like packaging, containers, and liners that do not require resistance to ultraviolet radiation. Selecting UV stabilized polyethylene ensures prolonged durability and performance in environments with direct UV exposure, unlike non-stabilized variants.

Environmental Impact and Degradation

UV stabilized polyethylene contains additives that significantly reduce photodegradation caused by sunlight exposure, enhancing its durability and extending its lifespan in outdoor environments. Non-stabilized polyethylene degrades faster under UV radiation, leading to the formation of microplastics and increased environmental pollution. The slower degradation of UV stabilized polyethylene results in less frequent replacement and reduced plastic waste accumulation, mitigating its overall environmental impact.

Choosing the Right Polyethylene for Your Needs

UV stabilized polyethylene incorporates additives that significantly enhance its resistance to ultraviolet radiation, making it ideal for outdoor applications where prolonged sun exposure is expected. Non-stabilized polyethylene lacks these additives and tends to degrade more quickly under UV light, leading to brittleness and reduced lifespan. Selecting the right polyethylene depends on factors such as environmental exposure, durability requirements, and cost considerations to ensure optimal performance and longevity.

UV Stabilized Polyethylene vs Non-Stabilized Polyethylene Infographic

materialdif.com

materialdif.com