Monomer recovery in polyethylene PET production involves reclaiming unreacted ethylene glycol and terephthalic acid to minimize waste and improve cost efficiency. Polymerization converts these monomers into long-chain polymers, determining the material's mechanical strength and clarity. Optimizing the balance between monomer recovery and polymerization enhances overall process sustainability and product quality.

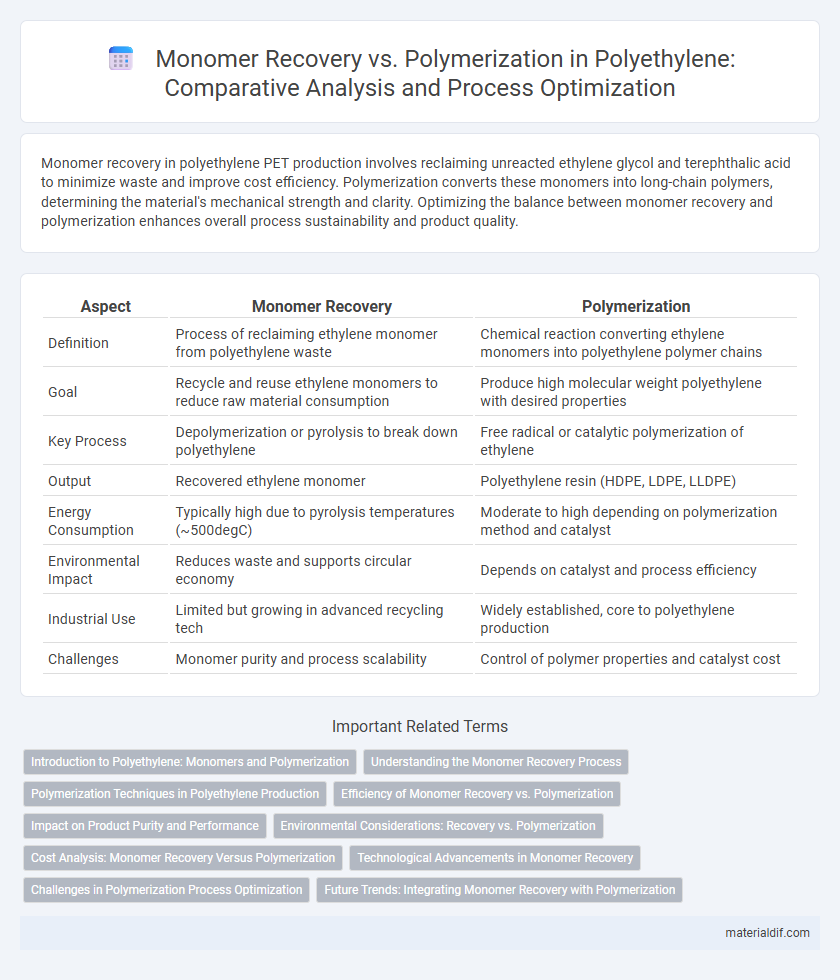

Table of Comparison

| Aspect | Monomer Recovery | Polymerization |

|---|---|---|

| Definition | Process of reclaiming ethylene monomer from polyethylene waste | Chemical reaction converting ethylene monomers into polyethylene polymer chains |

| Goal | Recycle and reuse ethylene monomers to reduce raw material consumption | Produce high molecular weight polyethylene with desired properties |

| Key Process | Depolymerization or pyrolysis to break down polyethylene | Free radical or catalytic polymerization of ethylene |

| Output | Recovered ethylene monomer | Polyethylene resin (HDPE, LDPE, LLDPE) |

| Energy Consumption | Typically high due to pyrolysis temperatures (~500degC) | Moderate to high depending on polymerization method and catalyst |

| Environmental Impact | Reduces waste and supports circular economy | Depends on catalyst and process efficiency |

| Industrial Use | Limited but growing in advanced recycling tech | Widely established, core to polyethylene production |

| Challenges | Monomer purity and process scalability | Control of polymer properties and catalyst cost |

Introduction to Polyethylene: Monomers and Polymerization

Polyethylene is synthesized through the polymerization of ethylene monomers, a process where monomer recovery plays a crucial role in optimizing production efficiency. Efficient monomer recovery techniques reduce waste and lower costs by capturing unreacted ethylene for reuse, enhancing overall polymerization yield. Understanding the balance between monomer recovery and polymerization dynamics is essential for producing high-quality polyethylene with desired molecular weight and properties.

Understanding the Monomer Recovery Process

Monomer recovery in polyethylene production involves capturing unreacted ethylene monomers from the polymerization reactor to enhance process efficiency and reduce waste. This process typically uses methods such as distillation and adsorption to separate and recycle the monomers back into the polymerization system, minimizing raw material consumption. Optimizing monomer recovery directly impacts polyethylene yield, product quality, and overall environmental footprint by lowering volatile organic compound emissions.

Polymerization Techniques in Polyethylene Production

Polymerization techniques in polyethylene production, including solution, slurry, and gas-phase polymerization, directly impact monomer recovery rates and overall process efficiency. Gas-phase polymerization offers superior monomer recovery due to its ability to recycle unreacted ethylene, minimizing waste and reducing production costs. Advanced catalyst systems like Ziegler-Natta and metallocene catalysts enhance polymerization control, leading to higher yields and optimized polyethylene properties while maintaining effective monomer utilization.

Efficiency of Monomer Recovery vs. Polymerization

Evaluating monomer recovery efficiency against polymerization efficiency is critical in polyethylene production, as higher monomer recovery reduces raw material waste and lowers production costs. Advanced recovery systems achieve over 95% reclamation of unreacted ethylene, directly impacting overall process sustainability and profitability. Balancing rapid polymerization rates with effective monomer recovery ensures optimized product quality and energy consumption.

Impact on Product Purity and Performance

Monomer recovery in polyethylene production significantly enhances product purity by minimizing residual monomer content, which improves the polymer's mechanical properties and thermal stability. Efficient polymerization processes reduce unreacted monomers, resulting in higher molecular weight distribution and consistent polymer morphology. Optimizing the balance between monomer recovery and polymerization directly influences polyethylene's performance in applications such as packaging, automotive parts, and consumer goods.

Environmental Considerations: Recovery vs. Polymerization

Monomer recovery in polyethylene production significantly reduces environmental impact by minimizing volatile organic compound emissions and decreasing raw material waste, enhancing sustainability. Polymerization processes, while energy-intensive, can be optimized using advanced catalysts to improve polymer yield and reduce greenhouse gas emissions. Balancing monomer recovery with efficient polymerization technologies is critical for lowering the carbon footprint of polyethylene manufacturing and supporting circular economy goals.

Cost Analysis: Monomer Recovery Versus Polymerization

Monomer recovery in polyethylene production significantly reduces raw material costs by recycling unreacted monomers, lowering overall feedstock expenses compared to initiating new polymerization cycles. Polymerization processes demand substantial energy inputs and catalyst usage, increasing operational costs, whereas efficient monomer recovery systems optimize resource utilization and improve economic feasibility. The cost analysis highlights that investing in advanced monomer recovery technologies can achieve higher profit margins through minimized waste and reduced dependency on fresh monomer supply.

Technological Advancements in Monomer Recovery

Technological advancements in monomer recovery during polyethylene production have significantly enhanced efficiency and reduced environmental impact. Innovative catalytic processes and membrane separation technologies enable higher purity recovery of ethylene monomers, minimizing waste and energy consumption. These improvements directly contribute to more sustainable polymerization cycles and increased overall yield in polyethylene manufacturing.

Challenges in Polymerization Process Optimization

Monomer recovery in polyethylene production significantly impacts polymerization process optimization by addressing challenges such as maintaining catalyst efficiency and controlling reaction kinetics. Inefficient monomer recovery can lead to accumulation of impurities and variation in monomer concentration, causing defects in polymer chain structure and inconsistent molecular weight distribution. Optimizing polymerization requires balancing recovery rates with reaction conditions to ensure stable polymer yields and high-quality polyethylene resin properties.

Future Trends: Integrating Monomer Recovery with Polymerization

Integrating monomer recovery directly within polyethylene polymerization processes enhances resource efficiency by reducing feedstock waste and lowering energy consumption. Advanced catalytic systems and reactor designs are emerging to enable in-situ monomer recycling, improving overall polymer yield and purity. Future trends highlight the development of circular polyethylene production methods that seamlessly combine polymerization with monomer recovery to support sustainable plastics manufacturing.

Monomer Recovery vs Polymerization Infographic

materialdif.com

materialdif.com