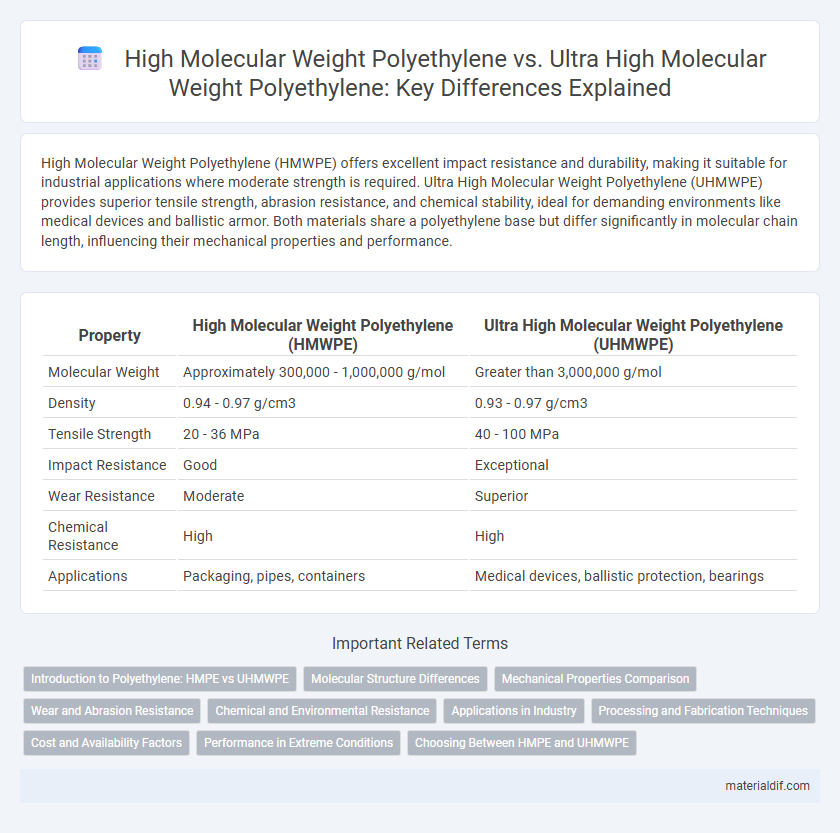

High Molecular Weight Polyethylene (HMWPE) offers excellent impact resistance and durability, making it suitable for industrial applications where moderate strength is required. Ultra High Molecular Weight Polyethylene (UHMWPE) provides superior tensile strength, abrasion resistance, and chemical stability, ideal for demanding environments like medical devices and ballistic armor. Both materials share a polyethylene base but differ significantly in molecular chain length, influencing their mechanical properties and performance.

Table of Comparison

| Property | High Molecular Weight Polyethylene (HMWPE) | Ultra High Molecular Weight Polyethylene (UHMWPE) |

|---|---|---|

| Molecular Weight | Approximately 300,000 - 1,000,000 g/mol | Greater than 3,000,000 g/mol |

| Density | 0.94 - 0.97 g/cm3 | 0.93 - 0.97 g/cm3 |

| Tensile Strength | 20 - 36 MPa | 40 - 100 MPa |

| Impact Resistance | Good | Exceptional |

| Wear Resistance | Moderate | Superior |

| Chemical Resistance | High | High |

| Applications | Packaging, pipes, containers | Medical devices, ballistic protection, bearings |

Introduction to Polyethylene: HMPE vs UHMWPE

High Molecular Weight Polyethylene (HMPE) and Ultra High Molecular Weight Polyethylene (UHMWPE) are both durable thermoplastics characterized by their exceptionally high molecular weights, with UHMWPE boasting molecules typically over 3.1 million g/mol compared to HMPE's lower range around 1 million g/mol. This molecular weight difference results in UHMWPE exhibiting superior wear resistance, impact strength, and chemical inertness, making it ideal for advanced applications such as medical implants and ballistic protection. HMPE, while robust and resistant to abrasion, serves well in industrial applications like ropes and nets, balancing strength with easier processability.

Molecular Structure Differences

High Molecular Weight Polyethylene (HMWPE) features longer polymer chains with moderate branching, resulting in enhanced tensile strength and toughness compared to standard polyethylene. Ultra High Molecular Weight Polyethylene (UHMWPE) consists of extremely long, linear polymer chains with minimal branching, providing superior impact resistance and exceptional abrasion resistance due to its highly crystalline molecular structure. The significantly higher molecular weight of UHMWPE leads to stronger intermolecular interactions and increased chain entanglement, distinguishing its physical properties from HMWPE.

Mechanical Properties Comparison

High Molecular Weight Polyethylene (HMWPE) exhibits excellent tensile strength and impact resistance, making it suitable for applications requiring durability and flexibility. Ultra High Molecular Weight Polyethylene (UHMWPE) surpasses HMWPE with superior abrasion resistance, higher tensile strength, and outstanding impact toughness due to its extremely long polymer chains. The enhanced mechanical properties of UHMWPE result in exceptional wear resistance and low friction, ideal for demanding industrial and medical applications.

Wear and Abrasion Resistance

Ultra High Molecular Weight Polyethylene (UHMWPE) exhibits significantly superior wear and abrasion resistance compared to High Molecular Weight Polyethylene (HMWPE) due to its longer polymer chains and higher molecular weight, which enhance durability. UHMWPE's dense molecular structure reduces friction and improves impact resistance, making it ideal for applications requiring extreme wear resistance such as medical implants, conveyor belts, and protective gear. The enhanced performance of UHMWPE in abrasive environments ensures extended service life and reduced maintenance compared to standard HMWPE materials.

Chemical and Environmental Resistance

High Molecular Weight Polyethylene (HMWPE) exhibits excellent chemical resistance to acids, bases, and organic solvents, making it suitable for various industrial applications. Ultra High Molecular Weight Polyethylene (UHMWPE) surpasses HMWPE in chemical inertness and provides superior resistance to abrasion and environmental stress cracking. UHMWPE's molecular structure enhances its durability in harsh chemical environments and extends its lifespan in outdoor and corrosive conditions.

Applications in Industry

High Molecular Weight Polyethylene (HMWPE) is widely used in packaging, automotive components, and containers due to its balance of toughness and processability. Ultra High Molecular Weight Polyethylene (UHMWPE) finds critical applications in medical implants, ballistic protection, and heavy-duty industrial machinery because of its exceptional abrasion resistance and impact strength. Industry sectors such as healthcare, defense, and manufacturing leverage UHMWPE for high-performance, durable solutions where wear resistance is paramount.

Processing and Fabrication Techniques

High Molecular Weight Polyethylene (HMWPE) offers excellent processability through conventional extrusion and injection molding techniques, making it suitable for a wide range of industrial applications. Ultra High Molecular Weight Polyethylene (UHMWPE), characterized by its extremely long polymer chains, requires specialized processing methods such as compression molding and ram extrusion due to its high viscosity and resistance to flow. Fabrication of UHMWPE often involves machining techniques like CNC milling and laser cutting to achieve precise shapes, whereas HMWPE can be fabricated using standard thermoplastic equipment.

Cost and Availability Factors

High Molecular Weight Polyethylene (HMWPE) offers a more cost-effective solution with greater availability compared to Ultra High Molecular Weight Polyethylene (UHMWPE), which demands higher production expenses due to its extended polymer chains. The enhanced mechanical properties of UHMWPE, such as superior abrasion resistance and impact strength, contribute to its increased price point and limited supply. HMWPE finds widespread use in applications requiring moderate durability at a lower cost, while UHMWPE is reserved for specialized, high-performance needs where cost is less of a constraint.

Performance in Extreme Conditions

Ultra High Molecular Weight Polyethylene (UHMWPE) outperforms High Molecular Weight Polyethylene (HMWPE) in extreme conditions due to its superior impact strength, abrasion resistance, and chemical stability. UHMWPE maintains structural integrity at low temperatures and exhibits exceptional wear resistance in aggressive environments, making it ideal for heavy-duty industrial applications. Its molecular weight, often exceeding 3 million g/mol, significantly enhances durability compared to HMWPE, which typically ranges between 100,000 and 500,000 g/mol.

Choosing Between HMPE and UHMWPE

High Molecular Weight Polyethylene (HMPE) offers excellent tensile strength and abrasion resistance, making it ideal for applications requiring durability and flexibility, such as ropes and protective gear. Ultra High Molecular Weight Polyethylene (UHMWPE) provides superior impact resistance and low friction properties, suitable for high-performance biomedical devices and bulletproof vests. Choosing between HMPE and UHMWPE depends on the specific mechanical requirements, cost considerations, and environmental exposure of the intended application.

High Molecular Weight Polyethylene vs Ultra High Molecular Weight Polyethylene Infographic

materialdif.com

materialdif.com