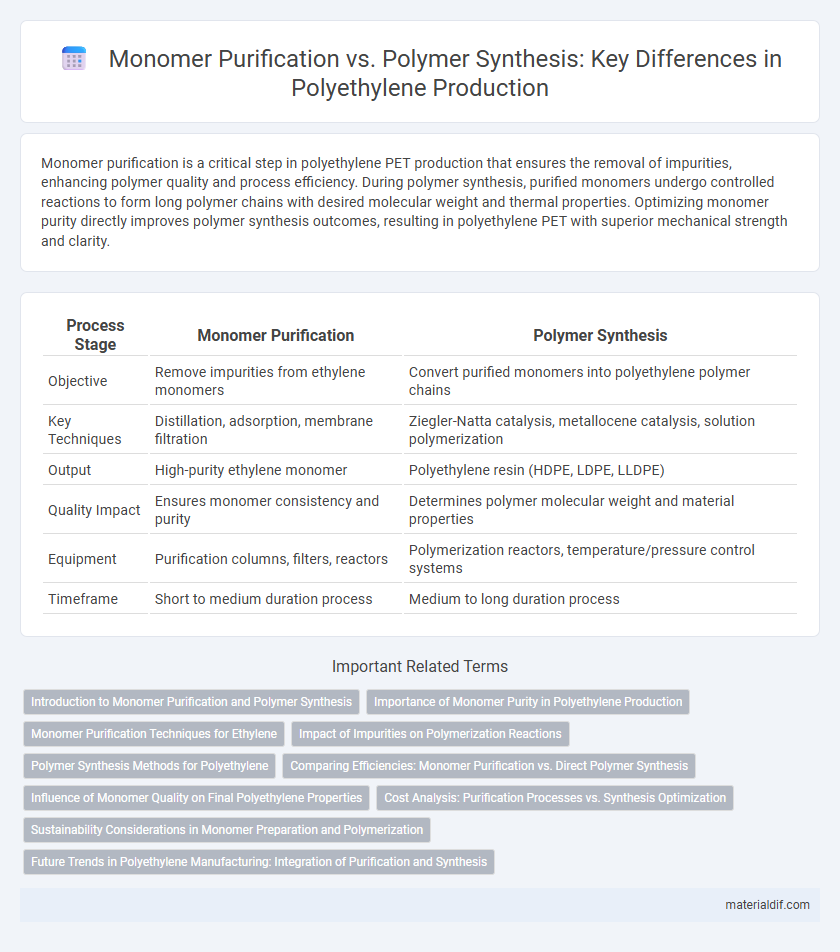

Monomer purification is a critical step in polyethylene PET production that ensures the removal of impurities, enhancing polymer quality and process efficiency. During polymer synthesis, purified monomers undergo controlled reactions to form long polymer chains with desired molecular weight and thermal properties. Optimizing monomer purity directly improves polymer synthesis outcomes, resulting in polyethylene PET with superior mechanical strength and clarity.

Table of Comparison

| Process Stage | Monomer Purification | Polymer Synthesis |

|---|---|---|

| Objective | Remove impurities from ethylene monomers | Convert purified monomers into polyethylene polymer chains |

| Key Techniques | Distillation, adsorption, membrane filtration | Ziegler-Natta catalysis, metallocene catalysis, solution polymerization |

| Output | High-purity ethylene monomer | Polyethylene resin (HDPE, LDPE, LLDPE) |

| Quality Impact | Ensures monomer consistency and purity | Determines polymer molecular weight and material properties |

| Equipment | Purification columns, filters, reactors | Polymerization reactors, temperature/pressure control systems |

| Timeframe | Short to medium duration process | Medium to long duration process |

Introduction to Monomer Purification and Polymer Synthesis

Monomer purification in polyethylene production involves removing impurities such as moisture, oxygen, and catalyst poisons to enhance polymer quality and process efficiency. Effective purification methods, including distillation and adsorption, ensure consistent reactor performance and polymer properties. Polymer synthesis subsequently converts purified ethylene monomers into polyethylene chains through controlled polymerization techniques like Ziegler-Natta or metallocene catalysis to achieve desired molecular weight and branching.

Importance of Monomer Purity in Polyethylene Production

Monomer purity critically influences polyethylene production, as impurities in ethylene can lead to defects in polymer chains, reducing molecular weight and overall polymer quality. Maintaining high-purity monomers minimizes catalyst poisoning, enhances polymerization efficiency, and ensures consistent mechanical properties in the final polyethylene product. Rigorous purification techniques such as distillation and adsorption are essential to achieving optimal monomer purity before polymer synthesis.

Monomer Purification Techniques for Ethylene

Ethylene monomer purification involves techniques such as distillation, adsorption, and membrane separation to remove impurities like acetylene, methane, and other hydrocarbons that affect polyethylene polymerization. High-purity ethylene ensures improved catalyst performance and polymer structure consistency during polymer synthesis processes such as Ziegler-Natta or metallocene catalysis. Efficient monomer purification leads to higher molecular weight polyethylene with enhanced mechanical and chemical properties.

Impact of Impurities on Polymerization Reactions

Impurities in monomer feedstocks critically affect polymerization reactions, often leading to incomplete polymerization and reduced polyethylene molecular weight. Residual catalysts or moisture can deactivate polymerization catalysts, causing defects like branching irregularities and diminished mechanical properties. Effective monomer purification ensures high catalyst efficiency and consistent polyethylene quality by minimizing these adverse effects during polymer synthesis.

Polymer Synthesis Methods for Polyethylene

Polyethylene polymer synthesis primarily utilizes catalytic processes such as Ziegler-Natta and metallocene catalysis, enabling precise control over molecular weight distribution and polymer architecture. Gas-phase, solution-phase, and slurry-phase polymerization reactors serve as standard industrial methods, each optimized for producing high-density polyethylene (HDPE), low-density polyethylene (LDPE), or linear low-density polyethylene (LLDPE). Advances in catalyst design continue to improve polymer properties like crystallinity, density, and branching, directly impacting mechanical strength and processability.

Comparing Efficiencies: Monomer Purification vs. Direct Polymer Synthesis

Monomer purification enhances polyethylene quality by reducing impurities that inhibit polymerization, resulting in higher molecular weight and improved mechanical properties. Direct polymer synthesis bypasses extensive purification, increasing production speed but potentially introducing defects that lower polymer consistency and durability. Optimizing the balance between purification and synthesis efficiency is critical for maximizing yield and material performance in industrial polyethylene manufacturing.

Influence of Monomer Quality on Final Polyethylene Properties

Monomer purification plays a critical role in determining the final polyethylene properties, as impurities such as sulfur or oxygen-containing compounds can act as polymerization inhibitors or chain transfer agents, adversely affecting polymer molecular weight distribution and thermal stability. High-purity ethylene monomer ensures consistent polymer synthesis, leading to improved mechanical strength, clarity, and chemical resistance in the resulting polyethylene. Optimizing monomer quality reduces defects and enhances polymer crystallinity, which directly influences tensile strength and impact resistance in commercial polyethylene products.

Cost Analysis: Purification Processes vs. Synthesis Optimization

Monomer purification in polyethylene production significantly increases operational costs due to energy-intensive processes such as distillation and drying, which require advanced equipment and maintenance. In contrast, optimizing polymer synthesis through catalyst development and process conditions can reduce raw material waste and reaction time, leading to more cost-effective production cycles. Balancing expenses between purification processes and synthesis optimization is crucial for minimizing overall manufacturing costs while maintaining product quality.

Sustainability Considerations in Monomer Preparation and Polymerization

Monomer purification for polyethylene production involves advanced techniques such as distillation and adsorption to minimize impurities that can deactivate catalysts, thereby enhancing polymerization efficiency and reducing waste. Sustainable polymer synthesis emphasizes energy-efficient catalytic processes like metallocene or Ziegler-Natta catalysis that lower greenhouse gas emissions and enable precise molecular weight control. Integrating green chemistry principles in monomer preparation and polymerization results in decreased solvent use, lower toxic byproducts, and improved recyclability of the final polyethylene product.

Future Trends in Polyethylene Manufacturing: Integration of Purification and Synthesis

Future trends in polyethylene manufacturing emphasize seamless integration of monomer purification with polymer synthesis to enhance product quality and process efficiency. Advanced catalytic systems and continuous purification techniques reduce impurities in ethylene feedstock, enabling precise control over polymer chain structure and molecular weight distribution. This integrated approach supports scalable production of high-performance polyethylene grades with tailored properties for diverse industrial applications.

Monomer Purification vs Polymer Synthesis Infographic

materialdif.com

materialdif.com