Crosslinked polyethylene (PEX) offers enhanced thermal resistance, chemical stability, and mechanical strength compared to non-crosslinked polyethylene, making it ideal for high-temperature applications such as plumbing and radiant heating systems. Non-crosslinked polyethylene, while more flexible and easier to process, lacks the durability and resistance to deformation found in PEX. The crosslinking process creates a three-dimensional network within the polymer, significantly improving its performance under stress and elevated temperatures.

Table of Comparison

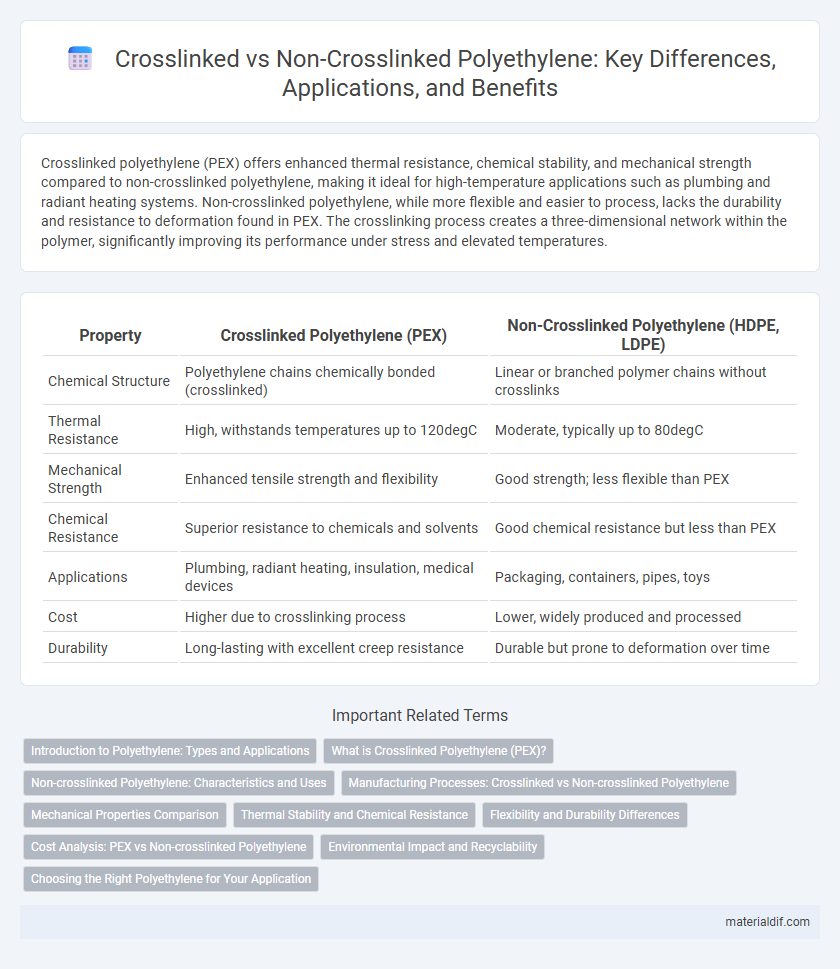

| Property | Crosslinked Polyethylene (PEX) | Non-Crosslinked Polyethylene (HDPE, LDPE) |

|---|---|---|

| Chemical Structure | Polyethylene chains chemically bonded (crosslinked) | Linear or branched polymer chains without crosslinks |

| Thermal Resistance | High, withstands temperatures up to 120degC | Moderate, typically up to 80degC |

| Mechanical Strength | Enhanced tensile strength and flexibility | Good strength; less flexible than PEX |

| Chemical Resistance | Superior resistance to chemicals and solvents | Good chemical resistance but less than PEX |

| Applications | Plumbing, radiant heating, insulation, medical devices | Packaging, containers, pipes, toys |

| Cost | Higher due to crosslinking process | Lower, widely produced and processed |

| Durability | Long-lasting with excellent creep resistance | Durable but prone to deformation over time |

Introduction to Polyethylene: Types and Applications

Crosslinked polyethylene (PEX) features a three-dimensional molecular network that enhances thermal resistance, mechanical strength, and chemical stability compared to non-crosslinked polyethylene (PE), which consists of linear or branched polymer chains. PEX is widely used in plumbing, radiant heating systems, and insulation due to its superior durability and flexibility, while non-crosslinked PE finds applications in packaging, containers, and films because of its ease of processing and cost-effectiveness. The choice between PEX and non-crosslinked PE depends on the specific requirements for temperature tolerance, mechanical properties, and environmental resistance in various industrial and consumer applications.

What is Crosslinked Polyethylene (PEX)?

Crosslinked Polyethylene (PEX) is a type of polyethylene that undergoes a chemical process to create a three-dimensional network of bonds, significantly enhancing its thermal, mechanical, and chemical resistance properties. This crosslinking improves PEX's durability, flexibility, and resistance to high temperatures and pressure, making it ideal for applications such as plumbing, radiant heating, and industrial piping. In contrast, non-crosslinked polyethylene lacks this bonded structure, resulting in lower heat resistance and mechanical strength.

Non-crosslinked Polyethylene: Characteristics and Uses

Non-crosslinked polyethylene (PE) features a linear molecular structure without chemical bonds linking polymer chains, resulting in high flexibility, ease of processing, and recyclability. Commonly used in packaging films, plastic bags, and containers, its excellent chemical resistance and low density make it ideal for lightweight, cost-effective applications. Unlike crosslinked polyethylene (PEX), non-crosslinked PE lacks enhanced thermal stability and mechanical strength but offers superior transparency and weldability for diverse industrial and consumer uses.

Manufacturing Processes: Crosslinked vs Non-crosslinked Polyethylene

Crosslinked polyethylene (PEX) is produced through chemical or physical crosslinking methods such as peroxide, silane, or irradiation processes that enhance thermal stability and mechanical strength by forming covalent bonds between polymer chains. Non-crosslinked polyethylene (PE), typically high-density polyethylene (HDPE) or low-density polyethylene (LDPE), is manufactured via polymerization processes like Ziegler-Natta or metallocene catalysis without subsequent crosslinking, resulting in a thermoplastic with linear or branched molecular structures. The manufacturing distinction impacts properties, with PEX offering superior temperature resistance and durability, while non-crosslinked PE remains easier to process and recycle due to its thermoplastic nature.

Mechanical Properties Comparison

Crosslinked polyethylene (PEX) exhibits superior mechanical properties compared to non-crosslinked polyethylene, including enhanced tensile strength, flexibility, and resistance to environmental stress cracking. The crosslinking process creates a three-dimensional network within the polymer matrix, improving impact resistance and dimensional stability under high temperatures. Non-crosslinked polyethylene tends to have lower mechanical durability and is more prone to deformation and failure under mechanical loads.

Thermal Stability and Chemical Resistance

Crosslinked polyethylene (PEX) exhibits superior thermal stability compared to non-crosslinked polyethylene, withstanding higher temperatures up to 120-130degC without deformation, ideal for plumbing and heating applications. Its enhanced chemical resistance resists solvents, fuels, and harsh chemicals more effectively than non-crosslinked polyethylene, which tends to soften and degrade under similar conditions. These properties make crosslinked polyethylene a preferred choice for industrial environments requiring long-term durability under thermal and chemical stress.

Flexibility and Durability Differences

Crosslinked polyethylene (PEX) exhibits superior flexibility due to its three-dimensional molecular network, allowing it to bend without cracking, unlike non-crosslinked polyethylene which tends to be more rigid. In terms of durability, PEX resists chemical degradation, high temperatures, and pressure much better than its non-crosslinked counterpart, making it ideal for demanding applications such as plumbing and radiant heating. Non-crosslinked polyethylene, while easier to manufacture and recycle, lacks the long-term resilience that crosslinked polyethylene provides.

Cost Analysis: PEX vs Non-crosslinked Polyethylene

Crosslinked polyethylene (PEX) generally has a higher upfront cost compared to non-crosslinked polyethylene due to its advanced manufacturing process and enhanced thermal and chemical resistance. Despite this, PEX often offers better long-term value by reducing maintenance and replacement expenses in applications such as plumbing and radiant heating systems. Non-crosslinked polyethylene is more economical initially but may incur higher operational costs over time because of lower durability and performance under stress conditions.

Environmental Impact and Recyclability

Crosslinked polyethylene (PEX) exhibits enhanced chemical and thermal stability, resulting in lower degradation rates but presents challenges in recyclability due to its irreversible crosslinked structure, which limits mechanical recycling options. Non-crosslinked polyethylene (LDPE, HDPE) offers higher recyclability through established mechanical recycling channels, contributing to reduced environmental impact by facilitating material recovery and reuse. The environmental footprint of non-crosslinked polyethylene is generally lower over the lifecycle, as it supports circular economy practices more effectively than crosslinked variants.

Choosing the Right Polyethylene for Your Application

Crosslinked polyethylene (PEX) offers enhanced thermal resistance and mechanical strength, making it ideal for plumbing, heating systems, and industrial applications requiring durability under high temperatures and pressures. Non-crosslinked polyethylene (PE), including HDPE and LDPE, provides flexibility, chemical resistance, and lower cost, suitable for packaging, containers, and general-purpose piping. Selecting the right polyethylene depends on factors like temperature tolerance, mechanical stress, chemical exposure, and application-specific requirements to ensure optimal performance and longevity.

Crosslinked Polyethylene vs Non-crosslinked Polyethylene Infographic

materialdif.com

materialdif.com