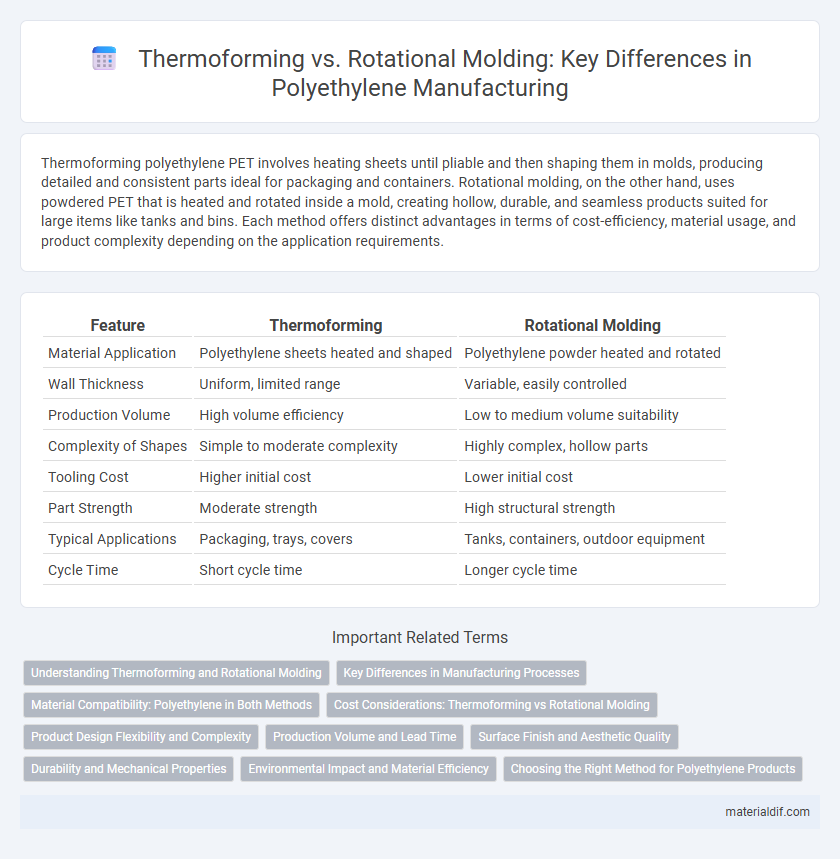

Thermoforming polyethylene PET involves heating sheets until pliable and then shaping them in molds, producing detailed and consistent parts ideal for packaging and containers. Rotational molding, on the other hand, uses powdered PET that is heated and rotated inside a mold, creating hollow, durable, and seamless products suited for large items like tanks and bins. Each method offers distinct advantages in terms of cost-efficiency, material usage, and product complexity depending on the application requirements.

Table of Comparison

| Feature | Thermoforming | Rotational Molding |

|---|---|---|

| Material Application | Polyethylene sheets heated and shaped | Polyethylene powder heated and rotated |

| Wall Thickness | Uniform, limited range | Variable, easily controlled |

| Production Volume | High volume efficiency | Low to medium volume suitability |

| Complexity of Shapes | Simple to moderate complexity | Highly complex, hollow parts |

| Tooling Cost | Higher initial cost | Lower initial cost |

| Part Strength | Moderate strength | High structural strength |

| Typical Applications | Packaging, trays, covers | Tanks, containers, outdoor equipment |

| Cycle Time | Short cycle time | Longer cycle time |

Understanding Thermoforming and Rotational Molding

Thermoforming shapes polyethylene sheets by heating them to a pliable state before molding them over a defined surface, ideal for creating thin-walled, detailed components. Rotational molding involves heating polyethylene powder inside a mold that rotates on multiple axes, producing hollow, seamless parts with uniform wall thickness. Understanding these processes highlights thermoforming's efficiency in high-volume production versus rotational molding's flexibility for custom, durable polyethylene products.

Key Differences in Manufacturing Processes

Thermoforming involves heating a polyethylene sheet until pliable, then shaping it over a mold using vacuum or pressure, allowing for fast production and detailed surface finishes. Rotational molding heats powdered polyethylene inside a hollow mold that rotates on multiple axes, producing uniform, hollow parts ideal for low-stress, seamless designs. The key differences lie in thermoforming's reliance on sheet materials and pressure forming versus rotational molding's use of powdered resin and slow, multi-axis heating for complex wall thickness distribution.

Material Compatibility: Polyethylene in Both Methods

Polyethylene exhibits excellent compatibility with both thermoforming and rotational molding due to its versatile thermal properties and chemical resistance. In thermoforming, polyethylene sheets are easily heated and shaped, enabling the production of thin, rigid components with precise details. Rotational molding leverages polyethylene's low melting point and homogenous material distribution to create seamless, hollow parts with uniform wall thickness.

Cost Considerations: Thermoforming vs Rotational Molding

Thermoforming generally incurs lower initial tooling and mold costs compared to rotational molding, making it cost-effective for high-volume production of thin-walled polyethylene parts. Rotational molding involves higher upfront investment due to complex molds but offers lower per-unit costs in low-to-medium volume runs and produces thicker, more durable polyethylene products. Choosing between these methods depends on production scale, part design complexity, and desired polyethylene thickness, with thermoforming favored for large quantities and rotational molding for versatile, robust components.

Product Design Flexibility and Complexity

Thermoforming offers limited product design flexibility, favoring simpler shapes and thin-walled components due to its pressure and vacuum forming process. Rotational molding provides greater design complexity, enabling the creation of hollow, intricate, and large polyethylene products with uniform wall thickness and minimal material stress. The choice between these methods impacts the ability to produce detailed, customized polyethylene parts with varying wall thicknesses and structural features.

Production Volume and Lead Time

Thermoforming is ideal for high production volumes, offering fast lead times due to its automated, continuous processing of polyethylene sheets. Rotational molding suits lower production volumes with longer lead times, as it involves slower cycle times and manual intervention in the polyethylene powder melting and cooling stages. Choosing between thermoforming and rotational molding depends on balancing production scale and delivery speed for polyethylene parts.

Surface Finish and Aesthetic Quality

Thermoforming of polyethylene produces smooth, high-gloss surface finishes ideal for visually appealing applications, offering precise detail and consistent texture. In contrast, rotational molding often results in a matte or textured surface with less refined aesthetics but excels in creating uniform thickness for complex shapes. The choice between thermoforming and rotational molding depends on prioritizing surface finish quality versus structural uniformity and design complexity in polyethylene manufacturing.

Durability and Mechanical Properties

Thermoforming polyethylene produces parts with higher tensile strength and better impact resistance due to uniform material distribution and controlled crystallinity. Rotational molding results in thicker walls with enhanced toughness and excellent fatigue resistance, ideal for large, hollow structures. Durability in thermoformed parts excels under dynamic loads, while rotationally molded items offer superior performance against environmental stress and long-term wear.

Environmental Impact and Material Efficiency

Thermoforming uses polyethylene sheets heated and shaped under pressure, resulting in minimal waste due to precise material usage and efficient energy consumption, which lowers its environmental footprint compared to rotational molding. Rotational molding, while versatile for complex shapes, involves longer cycle times and higher energy usage, leading to increased carbon emissions and less material efficiency as excess polyethylene often remains unused or trimmed. Choosing thermoforming enhances sustainability by optimizing polyethylene material utilization and reducing environmental impact through lower energy demands and waste generation.

Choosing the Right Method for Polyethylene Products

Thermoforming offers precise dimensional control and is ideal for producing thin-walled polyethylene products with smooth surfaces, making it suitable for packaging and automotive components. Rotational molding excels in creating large, hollow, and complex shapes with uniform wall thickness, often used for tanks, containers, and outdoor furniture. Selecting the right method depends on product size, wall thickness requirements, production volume, and design complexity to optimize performance and cost-efficiency.

Thermoforming vs Rotational molding Infographic

materialdif.com

materialdif.com