Oxo-biodegradable polyethylene incorporates pro-oxidant additives that accelerate its degradation under specific environmental conditions, offering a more sustainable alternative to conventional polyethylene which can persist in the environment for hundreds of years. Conventional polyethylene is highly resilient and resistant to biodegradation, leading to significant environmental pollution issues, especially in marine and landfill ecosystems. The integration of oxo-biodegradable technology enhances the lifecycle management of plastic products by promoting faster breakdown into micro-fragments, although concerns about complete mineralization and environmental impacts remain under scientific evaluation.

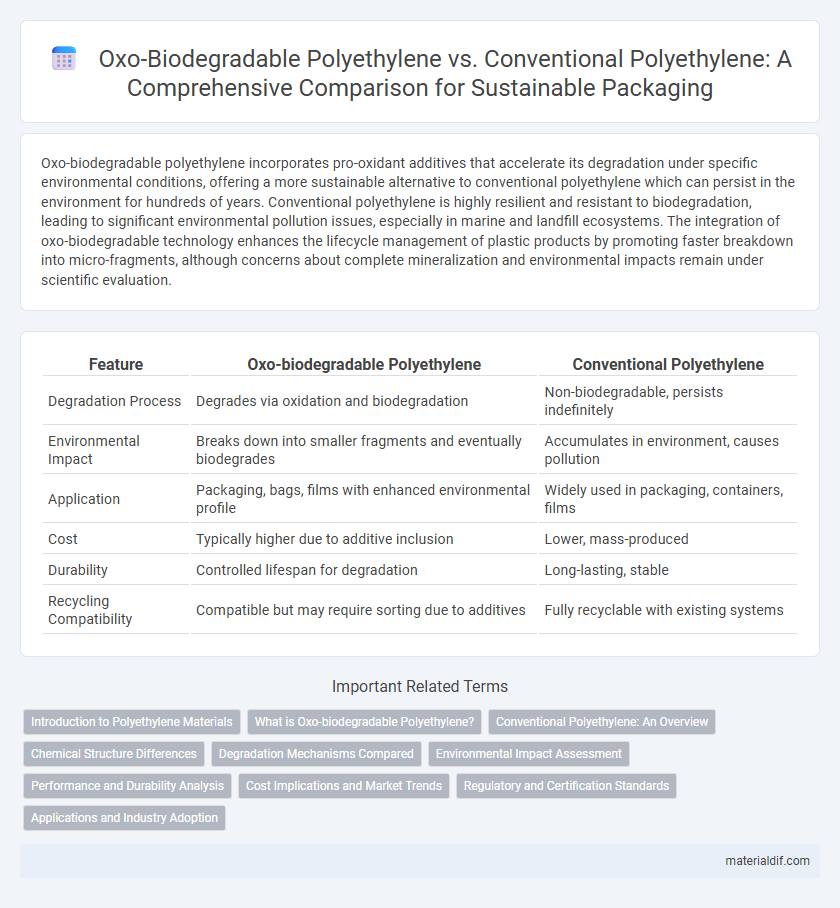

Table of Comparison

| Feature | Oxo-biodegradable Polyethylene | Conventional Polyethylene |

|---|---|---|

| Degradation Process | Degrades via oxidation and biodegradation | Non-biodegradable, persists indefinitely |

| Environmental Impact | Breaks down into smaller fragments and eventually biodegrades | Accumulates in environment, causes pollution |

| Application | Packaging, bags, films with enhanced environmental profile | Widely used in packaging, containers, films |

| Cost | Typically higher due to additive inclusion | Lower, mass-produced |

| Durability | Controlled lifespan for degradation | Long-lasting, stable |

| Recycling Compatibility | Compatible but may require sorting due to additives | Fully recyclable with existing systems |

Introduction to Polyethylene Materials

Polyethylene is a widely used polymer with variations including conventional polyethylene and oxo-biodegradable polyethylene, each differing in environmental impact and degradation properties. Conventional polyethylene is a durable, non-biodegradable plastic primarily made from ethylene monomers derived from petroleum, known for its resistance to chemicals and moisture. Oxo-biodegradable polyethylene incorporates pro-oxidant additives that trigger fragmentation under specific conditions, facilitating partial biodegradation and reducing long-term environmental persistence compared to conventional polyethylene.

What is Oxo-biodegradable Polyethylene?

Oxo-biodegradable polyethylene is a type of conventional polyethylene embedded with pro-oxidant additives that trigger fragmentation under specific environmental conditions such as sunlight, heat, and oxygen. This process accelerates the breakdown of polyethylene into micro-fragments, which are then further decomposed by microorganisms, enhancing its environmental degradability compared to conventional polyethylene. Unlike conventional polyethylene, which resists natural degradation and persists for centuries, oxo-biodegradable variants aim to reduce plastic pollution by promoting faster disintegration and biodegradation.

Conventional Polyethylene: An Overview

Conventional polyethylene is a widely used thermoplastic polymer derived from ethylene, characterized by its durability, flexibility, and resistance to moisture and chemicals. It is extensively employed in packaging, containers, and plastic films due to its high tensile strength and cost-effectiveness. However, its non-biodegradable nature contributes significantly to long-term environmental pollution, persisting in ecosystems for hundreds of years.

Chemical Structure Differences

Oxo-biodegradable polyethylene incorporates pro-oxidant additives, typically transition metal salts, which catalyze the oxidative degradation of the polymer chain, introducing carbonyl groups and facilitating fragmentation. Conventional polyethylene consists of long, saturated hydrocarbon chains with a highly stable carbon-carbon backbone, lacking functional groups that promote biodegradation. The chemical modification in oxo-biodegradable polyethylene disrupts the polymer's inert structure, enabling environmental breakdown that conventional polyethylene's purely hydrocarbon structure resists.

Degradation Mechanisms Compared

Oxo-biodegradable polyethylene undergoes degradation through a two-step process involving initial oxidative breakdown triggered by exposure to heat, UV light, or mechanical stress, leading to molecular fragmentation and formation of low-molecular-weight compounds that microbes can assimilate. Conventional polyethylene primarily relies on slow abiotic degradation, characterized by limited photodegradation and minimal microbial assimilation due to its high molecular weight and hydrophobicity. The incorporation of pro-oxidant additives in oxo-biodegradable polyethylene accelerates oxidation, enhancing fragmentation rates compared to the recalcitrant nature of conventional polyethylene.

Environmental Impact Assessment

Oxo-biodegradable polyethylene incorporates pro-oxidant additives that accelerate fragmentation under oxidative conditions, potentially reducing plastic pollution persistence compared to conventional polyethylene. Environmental impact assessments reveal that while oxo-biodegradable polyethylene degrades faster in terrestrial and marine environments, it may generate microplastics and does not fully mineralize into biomass or carbon dioxide. Conventional polyethylene exhibits high durability and resistance to degradation, leading to long-term environmental accumulation and greater challenges in waste management and ecosystem health.

Performance and Durability Analysis

Oxo-biodegradable polyethylene incorporates pro-oxidant additives that accelerate degradation under specific environmental conditions, resulting in a reduction of polymer chain length and mechanical properties over time. Conventional polyethylene maintains consistent performance and durability due to its long-chain polymer structure resistant to environmental stressors like UV radiation and microbial activity. Comparative analysis reveals that while oxo-biodegradable polyethylene offers enhanced environmental breakdown, it generally exhibits lower tensile strength and shorter service life compared to conventional polyethylene in long-term applications.

Cost Implications and Market Trends

Oxo-biodegradable polyethylene typically incurs higher production costs due to the incorporation of pro-oxidant additives, impacting its price competitiveness compared to conventional polyethylene. Market trends indicate rising demand for sustainable packaging solutions, prompting growth in oxo-biodegradable polyethylene despite cost challenges. Conventional polyethylene maintains dominance in sectors prioritizing low-cost and high durability materials.

Regulatory and Certification Standards

Oxo-biodegradable polyethylene complies with standards such as ASTM D6954 and BS8472, which assess oxidative and biodegradation phases, ensuring environmental safety and regulatory acceptance in regions promoting sustainable plastics. Conventional polyethylene, primarily regulated under ISO 9001 and FDA guidelines for food contact, lacks specific biodegradation certifications, posing challenges in meeting emerging circular economy mandates. Increasing regulatory focus on plastic waste reduction drives policy frameworks favoring oxo-biodegradable polyethylene certifications for market access in Europe and parts of Asia.

Applications and Industry Adoption

Oxo-biodegradable polyethylene is increasingly adopted in packaging, agricultural films, and single-use products due to its enhanced environmental degradation properties, meeting rising industry demands for sustainability. Conventional polyethylene remains dominant in long-lasting applications like automotive parts, construction materials, and durable goods because of its unmatched strength and chemical resistance. Market trends indicate a gradual shift toward oxo-biodegradable variants in consumer goods sectors seeking to reduce plastic waste while maintaining performance standards.

Oxo-biodegradable Polyethylene vs Conventional Polyethylene Infographic

materialdif.com

materialdif.com