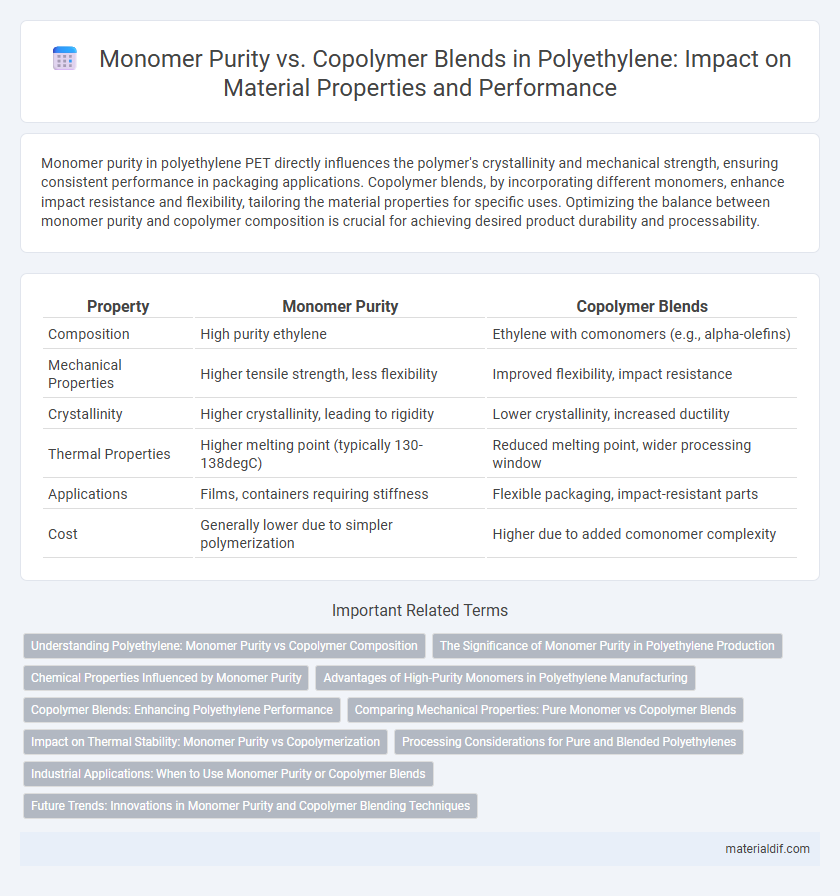

Monomer purity in polyethylene PET directly influences the polymer's crystallinity and mechanical strength, ensuring consistent performance in packaging applications. Copolymer blends, by incorporating different monomers, enhance impact resistance and flexibility, tailoring the material properties for specific uses. Optimizing the balance between monomer purity and copolymer composition is crucial for achieving desired product durability and processability.

Table of Comparison

| Property | Monomer Purity | Copolymer Blends |

|---|---|---|

| Composition | High purity ethylene | Ethylene with comonomers (e.g., alpha-olefins) |

| Mechanical Properties | Higher tensile strength, less flexibility | Improved flexibility, impact resistance |

| Crystallinity | Higher crystallinity, leading to rigidity | Lower crystallinity, increased ductility |

| Thermal Properties | Higher melting point (typically 130-138degC) | Reduced melting point, wider processing window |

| Applications | Films, containers requiring stiffness | Flexible packaging, impact-resistant parts |

| Cost | Generally lower due to simpler polymerization | Higher due to added comonomer complexity |

Understanding Polyethylene: Monomer Purity vs Copolymer Composition

Monomer purity in polyethylene synthesis critically influences polymer properties such as crystallinity, density, and mechanical strength, with higher purity leading to more consistent chain structures. Copolymer blends introduce comonomers like butene or hexene, adjusting crystallinity and enhancing impact resistance or flexibility by disrupting regular polymer chains. Balancing monomer purity and copolymer composition enables tailored polyethylene grades for specific applications, optimizing performance in packaging, automotive parts, and consumer goods.

The Significance of Monomer Purity in Polyethylene Production

Monomer purity plays a crucial role in polyethylene production by directly influencing polymer chain structure and material properties such as density, crystallinity, and mechanical strength. Impurities in monomers can disrupt polymerization, resulting in inconsistent copolymer blends and reduced performance in applications like packaging and automotive components. High monomer purity ensures uniform polymerization kinetics, leading to improved product quality and enhanced thermal and chemical resistance in polyethylene materials.

Chemical Properties Influenced by Monomer Purity

Monomer purity plays a critical role in defining the chemical properties of polyethylene, as impurities can introduce reactive sites that alter polymerization kinetics and final polymer structure. High-purity ethylene monomers lead to more consistent molecular weight distribution and enhanced crystallinity, improving mechanical strength and chemical resistance. In contrast, copolymer blends with different monomer units exhibit modified thermal stability and flexibility, directly influenced by the purity and composition of the initial monomers.

Advantages of High-Purity Monomers in Polyethylene Manufacturing

High-purity monomers enhance polyethylene manufacturing by producing polymers with consistent molecular weight distribution and superior mechanical properties. This leads to improved chemical resistance, clarity, and processability compared to copolymer blends, which may introduce variability due to mixed monomer incorporation. Utilizing high-purity monomers also reduces catalyst poisoning and by-product formation, resulting in higher polymer yield and efficiency.

Copolymer Blends: Enhancing Polyethylene Performance

Copolymer blends significantly enhance polyethylene performance by combining distinct monomer units to create materials with improved flexibility, impact resistance, and thermal stability. The integration of ethylene with comonomers such as butene, hexene, or octene in copolymer blends results in tailored molecular architectures that optimize mechanical properties and processability. Commercial applications benefit from these adaptations through enhanced durability in packaging, automotive components, and electrical insulation.

Comparing Mechanical Properties: Pure Monomer vs Copolymer Blends

Polyethylene derived from pure ethylene monomer exhibits higher tensile strength and crystallinity compared to copolymer blends, which typically show enhanced impact resistance and flexibility due to the presence of comonomers like butene or hexene. Copolymer blends demonstrate improved elongation at break and toughness, benefiting applications requiring durability under variable stress. Mechanical properties vary significantly with copolymer composition, affecting hardness, stiffness, and thermal resistance relative to pure monomer polyethylene.

Impact on Thermal Stability: Monomer Purity vs Copolymerization

Monomer purity significantly influences the thermal stability of polyethylene, as high-purity monomers produce polymers with fewer structural defects, thereby enhancing heat resistance. In contrast, copolymer blends introduce different monomer units that can disrupt polymer chain regularity, often resulting in varied thermal degradation profiles. Copolymerization allows tailoring thermal properties by adjusting comonomer type and concentration, balancing impact resistance and flexibility against thermal stability.

Processing Considerations for Pure and Blended Polyethylenes

Monomer purity in polyethylene production significantly influences processing parameters such as melt flow index, crystallinity, and thermal stability, resulting in more predictable extrusion and molding outcomes. Copolymer blends introduce variations in chain architecture and comonomer distribution, which affect viscosity and mechanical properties, necessitating adjusted processing conditions including temperature profiles and shear rates. Optimization of processing for both pure and blended polyethylenes demands precise control over polymer composition to achieve desired product performance while minimizing defects and energy consumption.

Industrial Applications: When to Use Monomer Purity or Copolymer Blends

Monomer purity in polyethylene production ensures consistent mechanical and chemical properties, ideal for high-performance industrial applications like food packaging and medical devices requiring strict FDA compliance. Copolymer blends provide enhanced impact resistance and flexibility, making them suitable for automotive parts and construction materials where durability and adaptability to environmental stress are critical. Selecting monomer purity or copolymer blends depends on the specific functional demands, cost-effectiveness, and regulatory standards of the target industrial application.

Future Trends: Innovations in Monomer Purity and Copolymer Blending Techniques

Future trends in polyethylene manufacturing emphasize advancing monomer purity to enhance polymer consistency and mechanical properties, minimizing impurities that affect polymerization kinetics. Innovations in copolymer blending techniques focus on precision control of molecular architecture, enabling tailored thermal and chemical resistance for specialized applications. Cutting-edge catalytic processes and real-time analytic tools drive these improvements, fostering the development of high-performance, customizable polyethylene materials.

Monomer purity vs Copolymer blends Infographic

materialdif.com

materialdif.com