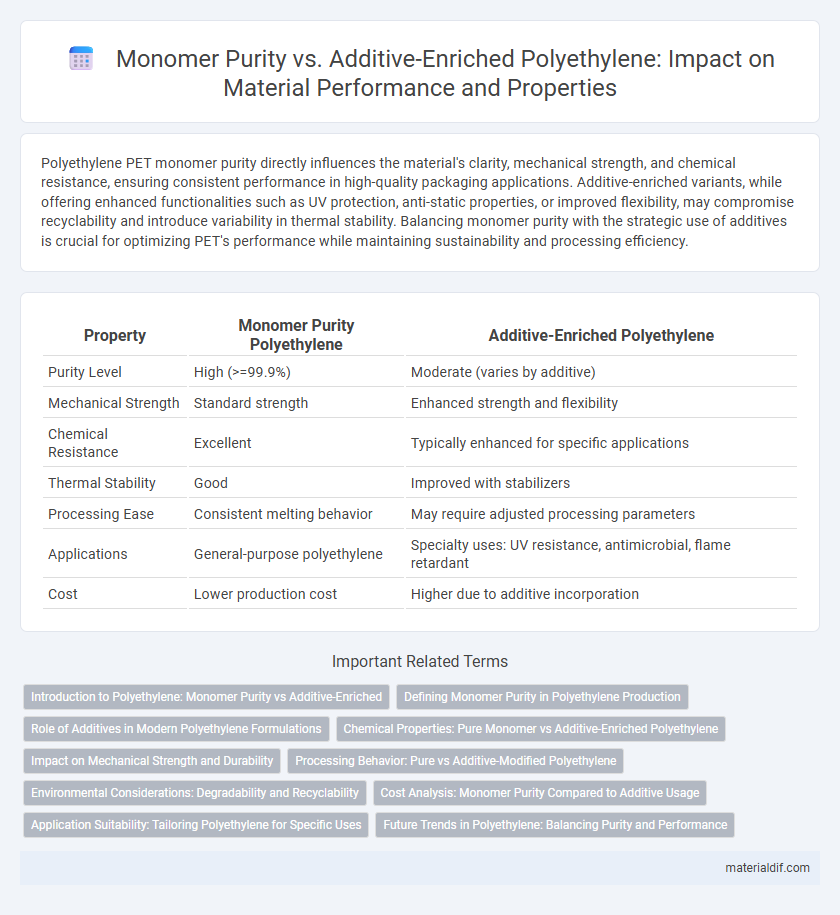

Polyethylene PET monomer purity directly influences the material's clarity, mechanical strength, and chemical resistance, ensuring consistent performance in high-quality packaging applications. Additive-enriched variants, while offering enhanced functionalities such as UV protection, anti-static properties, or improved flexibility, may compromise recyclability and introduce variability in thermal stability. Balancing monomer purity with the strategic use of additives is crucial for optimizing PET's performance while maintaining sustainability and processing efficiency.

Table of Comparison

| Property | Monomer Purity Polyethylene | Additive-Enriched Polyethylene |

|---|---|---|

| Purity Level | High (>=99.9%) | Moderate (varies by additive) |

| Mechanical Strength | Standard strength | Enhanced strength and flexibility |

| Chemical Resistance | Excellent | Typically enhanced for specific applications |

| Thermal Stability | Good | Improved with stabilizers |

| Processing Ease | Consistent melting behavior | May require adjusted processing parameters |

| Applications | General-purpose polyethylene | Specialty uses: UV resistance, antimicrobial, flame retardant |

| Cost | Lower production cost | Higher due to additive incorporation |

Introduction to Polyethylene: Monomer Purity vs Additive-Enriched

Polyethylene production fundamentally depends on the purity of the ethylene monomer, as high monomer purity ensures consistent polymer chain length and desirable mechanical properties. Additive-enriched polyethylene formulations incorporate stabilizers, antioxidants, and processing aids to enhance durability, thermal stability, and resistance to environmental stress cracking. The balance between monomer purity and additive content directly influences the final polymer's performance, processing behavior, and application suitability across industries.

Defining Monomer Purity in Polyethylene Production

Monomer purity in polyethylene production refers to the concentration of ethylene monomer free from contaminants and impurities that can affect polymerization efficiency and final resin properties. High monomer purity ensures consistent molecular weight distribution, enhanced mechanical strength, and improved clarity in polyethylene products. Additive-enriched systems introduce catalysts and stabilizers during polymerization, which can interact with monomer purity and require precise control to optimize polymer performance and processing characteristics.

Role of Additives in Modern Polyethylene Formulations

Additives in modern polyethylene formulations significantly enhance polymer performance by improving properties such as UV resistance, impact strength, and processability, which monomer purity alone cannot achieve. High monomer purity ensures base polymer consistency, but additives like antioxidants, slip agents, and nucleating agents tailor polyethylene to specific applications and environmental conditions. Balancing monomer purity with targeted additives enables optimized mechanical, thermal, and chemical properties crucial for advanced industrial and consumer uses.

Chemical Properties: Pure Monomer vs Additive-Enriched Polyethylene

Pure monomer polyethylene exhibits consistent chemical properties such as higher crystallinity and uniform molecular weight distribution, resulting in enhanced tensile strength and chemical resistance. Additive-enriched polyethylene contains stabilizers, antioxidants, and plasticizers that modify its chemical behavior, improving UV resistance and flexibility but potentially reducing crystallinity. The presence of these additives alters reaction kinetics during polymerization, influencing thermal stability and degradation patterns compared to pure monomer-based polyethylene.

Impact on Mechanical Strength and Durability

Monomer purity in polyethylene directly influences crystallinity, enhancing mechanical strength and long-term durability by reducing structural defects. Additive-enriched polyethylene formulations often incorporate stabilizers, plasticizers, and impact modifiers that improve flexibility and resistance to environmental stress cracking, but excessive additives can compromise tensile strength. Balancing monomer purity with optimized additive levels is critical to achieving desired performance characteristics in applications requiring robust mechanical integrity and extended service life.

Processing Behavior: Pure vs Additive-Modified Polyethylene

Monomer purity in polyethylene ensures consistent molecular weight distribution and crystallinity, resulting in predictable processing behavior such as uniform melt flow and thermal stability. Additive-enriched polyethylene, containing stabilizers, antioxidants, and fillers, exhibits modified rheological properties, enhanced thermal resistance, and improved mechanical strength during extrusion and molding. Processing parameters must be adjusted for additive-modified polyethylene to optimize flow characteristics and prevent degradation compared to pure polyethylene derived from high-purity monomers.

Environmental Considerations: Degradability and Recyclability

Monomer purity in polyethylene production enhances polymer consistency, resulting in improved recyclability by reducing contaminants that hinder reprocessing efficiency. Additive-enriched polyethylene often contains stabilizers and plasticizers that can negatively impact environmental degradability by prolonging polymer lifespans and complicating chemical breakdown. Balancing monomer purity with carefully selected additives is critical for optimizing both performance and environmental sustainability in polyethylene applications.

Cost Analysis: Monomer Purity Compared to Additive Usage

Monomer purity directly influences the overall cost of polyethylene production by reducing the need for costly additives that enhance polymer properties. High-purity monomers minimize impurities, leading to fewer processing steps and lower additive consumption, thereby decreasing raw material and operational expenses. Evaluating the cost-benefit ratio reveals that investing in monomer purification can offset additive costs and improve product performance efficiency.

Application Suitability: Tailoring Polyethylene for Specific Uses

Monomer purity in polyethylene production ensures high molecular uniformity and enhanced mechanical properties, making it ideal for medical and food packaging applications requiring strict safety standards. Additive-enriched polyethylene incorporates stabilizers, UV blockers, and impact modifiers, optimizing the material for outdoor use, automotive parts, and heavy-duty industrial products. Tailoring the balance between monomer purity and additives allows manufacturers to meet precise performance criteria and regulatory requirements for specific end-use applications.

Future Trends in Polyethylene: Balancing Purity and Performance

Future trends in polyethylene emphasize optimizing monomer purity levels to enhance polymer consistency while integrating additive-enriched formulations for tailored performance characteristics. Emerging technologies focus on advanced catalyst designs and purification processes to reduce impurities, thereby improving mechanical strength and chemical resistance. Concurrently, innovative additives such as antioxidants, UV stabilizers, and flame retardants are being strategically incorporated to meet specific application demands and environmental regulations.

Monomer purity vs Additive-enriched Infographic

materialdif.com

materialdif.com