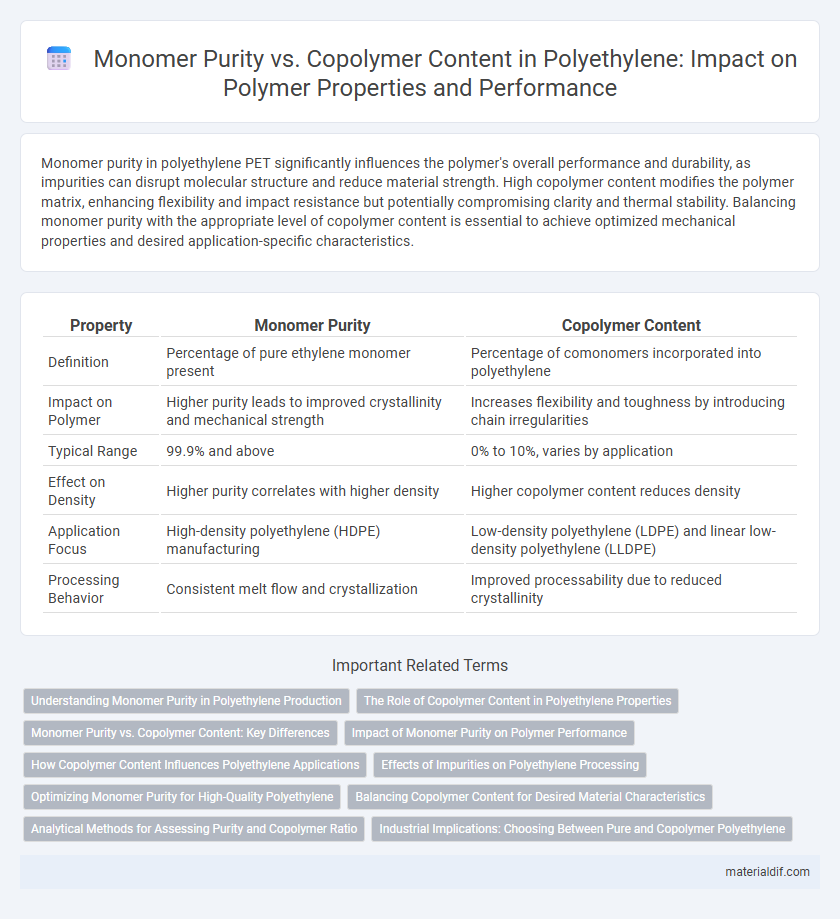

Monomer purity in polyethylene PET significantly influences the polymer's overall performance and durability, as impurities can disrupt molecular structure and reduce material strength. High copolymer content modifies the polymer matrix, enhancing flexibility and impact resistance but potentially compromising clarity and thermal stability. Balancing monomer purity with the appropriate level of copolymer content is essential to achieve optimized mechanical properties and desired application-specific characteristics.

Table of Comparison

| Property | Monomer Purity | Copolymer Content |

|---|---|---|

| Definition | Percentage of pure ethylene monomer present | Percentage of comonomers incorporated into polyethylene |

| Impact on Polymer | Higher purity leads to improved crystallinity and mechanical strength | Increases flexibility and toughness by introducing chain irregularities |

| Typical Range | 99.9% and above | 0% to 10%, varies by application |

| Effect on Density | Higher purity correlates with higher density | Higher copolymer content reduces density |

| Application Focus | High-density polyethylene (HDPE) manufacturing | Low-density polyethylene (LDPE) and linear low-density polyethylene (LLDPE) |

| Processing Behavior | Consistent melt flow and crystallization | Improved processability due to reduced crystallinity |

Understanding Monomer Purity in Polyethylene Production

Monomer purity directly impacts the structural consistency and mechanical properties of polyethylene, influencing polymerization efficiency and end-product quality. High monomer purity reduces unwanted side reactions during copolymerization, resulting in more precise control over copolymer content and polymer architecture. Controlling impurities such as oxygen, moisture, and residual catalysts ensures optimal polymer chain formation, enhancing polyethylene's thermal stability and durability.

The Role of Copolymer Content in Polyethylene Properties

Copolymer content in polyethylene significantly influences its mechanical and thermal properties, with higher copolymer incorporation typically enhancing flexibility and impact resistance while reducing crystallinity. The purity of the monomer directly affects the consistency and performance of the copolymer, as impurities can disrupt polymerization and alter the copolymer distribution. Optimizing copolymer content allows for tailored polyethylene materials suited for applications ranging from packaging films to high-strength automotive components.

Monomer Purity vs. Copolymer Content: Key Differences

Monomer purity directly influences the polymerization efficiency and the structural consistency of polyethylene, affecting its mechanical properties and application suitability. In contrast, copolymer content determines the polymer's thermal flexibility and chemical resistance by incorporating different monomer units into the polyethylene chain. Understanding the key differences between monomer purity and copolymer content is essential for optimizing polyethylene production processes and tailoring material characteristics.

Impact of Monomer Purity on Polymer Performance

High monomer purity in polyethylene production directly enhances polymer performance by minimizing impurities that can cause defects and degrade mechanical properties. Elevated purity levels result in polymers with improved tensile strength, clarity, and consistent molecular weight distribution. Conversely, lower monomer purity increases copolymer content variations, leading to reduced polymer durability and processing efficiency.

How Copolymer Content Influences Polyethylene Applications

Copolymer content in polyethylene significantly impacts its mechanical properties, such as flexibility, tensile strength, and chemical resistance, enabling tailored applications across industries. Higher copolymer content typically enhances impact resistance and processability, making it ideal for packaging films, automotive parts, and piping systems. Precise control of monomer purity and copolymer ratios optimizes performance characteristics for specific end-use requirements.

Effects of Impurities on Polyethylene Processing

Monomer purity significantly impacts polyethylene processing by influencing the physical properties and consistency of the final polymer product. Impurities in monomers can alter copolymer content, leading to variations in molecular weight distribution, melt flow index, and mechanical strength. Controlling these impurities ensures enhanced polymerization efficiency and improved film clarity, tensile strength, and processing stability in polyethylene manufacturing.

Optimizing Monomer Purity for High-Quality Polyethylene

Optimizing monomer purity directly influences the copolymer content and overall quality of polyethylene, as impurities can disrupt polymerization processes and degrade material properties. High monomer purity ensures consistent molecular weight distribution and enhances mechanical strength, chemical resistance, and clarity of the final polyethylene product. Controlling feedstock purity through advanced purification techniques is essential to achieve superior performance in applications requiring high-density polyethylene and linear low-density polyethylene grades.

Balancing Copolymer Content for Desired Material Characteristics

Achieving optimal polyethylene performance requires carefully balancing monomer purity with copolymer content to tailor mechanical properties and chemical resistance. High monomer purity minimizes unwanted side reactions, while controlled copolymer incorporation adjusts density and flexibility for specific applications. Precise regulation of ethylene and comonomer ratios directly influences crystallinity, impact strength, and processing behavior in polyethylene products.

Analytical Methods for Assessing Purity and Copolymer Ratio

Analytical methods for assessing monomer purity and copolymer content in polyethylene primarily include gas chromatography (GC) and nuclear magnetic resonance (NMR) spectroscopy, which provide precise quantification of residual monomers and copolymer ratios. Fourier-transform infrared spectroscopy (FTIR) is frequently utilized to identify functional groups and determine copolymer composition by analyzing characteristic absorption bands. High-performance liquid chromatography (HPLC) also plays a role in separating and quantifying polymer components, ensuring accurate evaluation of purity and copolymer distribution.

Industrial Implications: Choosing Between Pure and Copolymer Polyethylene

Monomer purity directly affects the mechanical properties and processability of polyethylene, with higher purity leading to more consistent polymer chains and enhanced material strength for industrial applications. Copolymer content introduces comonomers that modify crystallinity and flexibility, impacting impact resistance and environmental stress crack resistance, crucial for specific product requirements. Industrial decision-making balances cost considerations and performance demands, where pure polyethylene suits applications requiring rigidity and clarity, while copolymers are preferred for products needing toughness and improved low-temperature performance.

Monomer Purity vs Copolymer Content Infographic

materialdif.com

materialdif.com