Monomer purity in polyethylene PET directly impacts the polymer's mechanical strength and clarity, ensuring higher performance in packaging and industrial applications. In contrast, monomer blends may introduce variability in molecular weight distribution and crystallinity, potentially reducing consistency and durability. Optimizing monomer purity enhances processability and final product quality, making it the preferred choice for high-grade polyethylene PET production.

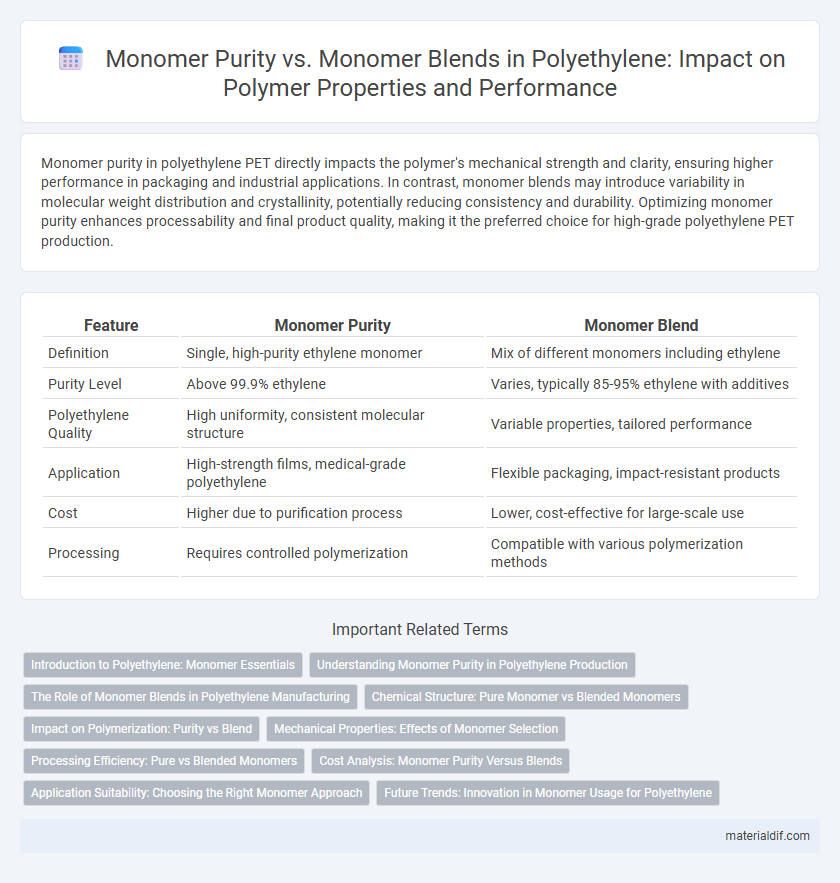

Table of Comparison

| Feature | Monomer Purity | Monomer Blend |

|---|---|---|

| Definition | Single, high-purity ethylene monomer | Mix of different monomers including ethylene |

| Purity Level | Above 99.9% ethylene | Varies, typically 85-95% ethylene with additives |

| Polyethylene Quality | High uniformity, consistent molecular structure | Variable properties, tailored performance |

| Application | High-strength films, medical-grade polyethylene | Flexible packaging, impact-resistant products |

| Cost | Higher due to purification process | Lower, cost-effective for large-scale use |

| Processing | Requires controlled polymerization | Compatible with various polymerization methods |

Introduction to Polyethylene: Monomer Essentials

Monomer purity in polyethylene production directly impacts polymer properties, with high-purity ethylene monomer yielding more consistent polymer chains and enhanced mechanical strength. In contrast, monomer blends, often containing comonomers like alpha-olefins, influence the polymer's density and crystallinity, tailoring material flexibility and toughness. Understanding the balance between monomer purity and blend composition is essential for optimizing polyethylene performance for specific applications.

Understanding Monomer Purity in Polyethylene Production

Monomer purity in polyethylene production critically influences polymer quality, affecting molecular weight distribution and mechanical properties. High-purity ethylene monomers lead to more consistent polymerization reactions and improved polyethylene performance, whereas monomer blends can introduce impurities that disrupt catalyst efficiency and polymer uniformity. Optimizing ethylene feedstock purity supports enhanced polymer chain structure, resulting in superior tensile strength and durability of the final polyethylene product.

The Role of Monomer Blends in Polyethylene Manufacturing

Monomer blends in polyethylene manufacturing enhance polymer properties by combining ethylene with comonomers like 1-butene, hexene, or octene, optimizing density and molecular weight distribution. Unlike monomer purity, which targets high-purity ethylene for consistent polymerization, monomer blends enable tailored polyethylene grades for specific applications such as film, pipe, or containers. The controlled ratio of comonomers in blends influences branching, crystallinity, and mechanical performance, driving innovation in high-density and linear low-density polyethylene production.

Chemical Structure: Pure Monomer vs Blended Monomers

Polyethylene produced from pure monomer exhibits a uniform chemical structure with consistent polymer chain lengths, resulting in predictable mechanical and thermal properties. In contrast, monomer blends introduce variability in chain branching and molecular weight distribution due to the presence of different monomer types, which can enhance impact resistance and flexibility but may reduce homogeneity. The purity of the monomer directly influences polymer crystallinity, density, and overall performance characteristics critical for specific applications.

Impact on Polymerization: Purity vs Blend

Monomer purity significantly influences polymerization efficiency and final polyethylene properties by reducing catalyst poisoning and enabling consistent molecular weight distribution. In contrast, monomer blends introduce variability in reactivity ratios and impurities that can lead to heterogeneous polymer chains and inconsistent polymerization kinetics. Controlling monomer purity is critical for achieving targeted mechanical strength and thermal stability in polyethylene production.

Mechanical Properties: Effects of Monomer Selection

Monomer purity significantly influences the mechanical properties of polyethylene, with high-purity monomers producing polymers with greater tensile strength and improved impact resistance due to uniform chain structures. In contrast, monomer blends often introduce compositional heterogeneity, leading to variations in crystallinity that can reduce stiffness and elongation at break. Selecting monomers with precise purity levels enables tailored mechanical performance, optimizing polyethylene for specific applications such as film strength or pipe durability.

Processing Efficiency: Pure vs Blended Monomers

Pure monomers in polyethylene production offer higher processing efficiency due to consistent polymerization rates and reduced catalyst deactivation, leading to uniform polymer properties. In contrast, monomer blends can introduce variability in reaction kinetics, causing fluctuations in molecular weight distribution and affecting the final polymer quality. Optimizing monomer purity minimizes impurities that interfere with catalyst activity, enabling smoother extrusion and higher throughput in polyethylene manufacturing.

Cost Analysis: Monomer Purity Versus Blends

High monomer purity in polyethylene production significantly elevates raw material costs but enhances polymer quality, leading to superior mechanical properties and processability. Monomer blends reduce feedstock expenses by incorporating lower-grade monomers, yet may compromise polymer performance and increase downstream processing complexity. Cost analysis reveals that optimizing the balance between monomer purity and blend ratios is crucial for minimizing overall production costs while maintaining targeted polyethylene specifications.

Application Suitability: Choosing the Right Monomer Approach

High monomer purity in polyethylene production ensures consistent polymer chain structure, enhancing mechanical properties and making it ideal for high-performance applications such as medical-grade films and food packaging. Monomer blends, offering cost efficiency and tailored polymer characteristics, suit applications like household containers and agricultural films where exact purity is less critical. Selecting the right monomer approach hinges on balancing performance requirements and economic factors related to the intended polyethylene application.

Future Trends: Innovation in Monomer Usage for Polyethylene

Future trends in polyethylene production emphasize enhanced monomer purity to improve polymer consistency, mechanical properties, and processing efficiency. Innovations in monomer blend formulations aim to create tailored polyethylene variants with optimized crystallinity and molecular weight distribution for specific applications. Advances in catalytic processes and in-line monitoring technologies drive the shift towards customizable monomer blends, balancing cost-effectiveness with performance.

Monomer purity vs Monomer blend Infographic

materialdif.com

materialdif.com